Abstract

Interfacial temperatures and pressures in liquid and vapor phases near liquid–vapor interfaces in pool boiling experiment for titanium tetrachloride have been measured recently. The interfacial vapor temperature is higher than that of liquid phase. Specific entropy generation rate increases with net boiling flux, as does the temperature discontinuity. Although the discontinuities in the temperatures and the chemical potential exist across the interfaces, the Δsiso can be zero when a physical relation should be provided between the properties in each phase. The entropy generation rate depends on conditions existing in that phase and that in each phase near liquid–vapor interfaces.

Similar content being viewed by others

Abbreviations

- A :

-

Boiling area

- d 1 :

-

Distance (mm)

- h :

-

Specific enthalpy

- Δh r :

-

Latent heat of vaporization (J mol−1)

- k :

-

Thermal conductivity of pure copper (W m−1 K−1)

- n :

-

Net boiling flux (mol m−2 s−1)

- Δn :

-

Micro-molecules of the titanium tetrachloride

- N :

-

Molecules of the titanium tetrachloride

- p :

-

Pressure

- Q :

-

Heat flux (kW m−2)

- s :

-

Specific entropy

- S :

-

Entropy

- Δs iso :

-

Specific entropy generation rate (kJ mol−1 K−1)

- S iso :

-

Total entropy of the isolated system

- S g :

-

Interfacial entropy generation rate (kJ m−2 s−1 K−1)

- T, T 1, T 2 :

-

Temperature (K)

- u :

-

Intensive internal energy of the surface phase

- U l :

-

Internal energy of the liquid

- σ :

-

Surface tension

- μ :

-

Chemical potential

- l:

-

Liquid phase

- v:

-

Vapor phase

- s:

-

Interface phase

References

Nagesh CHRVS, Rao CS, Ballal NB, Rao PK. Mechanism of titanium sponge formation in the kroll reduction reactor. Metall Mater Trans B. 2004;35(1):65–74.

Wenhao W, Fuzhong W. Exergy destruction analysis of heat exchanger in waste heat recovery system in Kroll process. Int J Exergy. 2017;22(1):89–101. https://doi.org/10.1504/IJEX.2017.10001122.

Wenhao W, Fuzhong W, Qingbo Y. Feasibility study for recovering waste heat in reduction system of Kroll process Energy analysis and economic valuation. Russ J Non-ferr Met. 2017;58(3):258–68. https://doi.org/10.3103/S1067821217030208.

Subramanyam RB, Sundaram CV. Development of technologies for large scale production of titanium and magnesium metals at the defence metallurgical research laboratory, Hyderabad. Bull Mater Sci. 1996;19(6):921–38.

Yuya K, Akihiro K, Tetsuya U. New smelting process for titanium: magnesiothermic reduction of TiCl4 into liquid Bi and subsequent refining by vacuum distillation. Metall Mater Trans B. 2015;46B(1):57–61.

Lee JC, Sohn HS, Jung JY. Effect of TiCl4 feeding rate on the formation of titanium sponge in the Kroll process. Kor J Met Mater. 2012;50(10):745–51. https://doi.org/10.3365/kjmm.2012.50.10.745.

Kiyoshi S, Masanori Y, Hiroyuki K, Seiyu T, Susumu K. Temperature measurement in a titanium sponge and mathematical modeling for the vacuum distillation in kroll process. J MMIJ. 1996;112(4):257–62. https://doi.org/10.2473/shigentosozai.112.257.

Putilin AI. A new hydrodynamic theory of forming block titanium sponge. JOM. 2011;63(5):66–8.

Osamu T, Toru HO. High-speed titanium production by magnesiothermic reduction of titanium trichloride. Mater Trans. 2006;47(4):1145–54.

Hildenbrand DL. Low-lying electronic states and revised thermochemistry of TiCl, TiCl2, and TiCl3. J Phys Chem A. 2009;113(8):1472–4.

Osamu T, Toru HO. Fundamental study on magnesiothermic reduction of titanium dichloride. Metall Mater Trans B. 2006;37B(5):823–30.

Fuzhong W, Chengtao G, Huixin J, Shouhua D. Analysis of energy for deoxidization-distillation process in titanium sponge combination production technology. Appl Mech Mater. 2013;368–370:697–701. https://doi.org/10.4028/www.scientific.net/AMM.368-370.697.

Burande CS, Bhalekar AA. Thermodynamic stability of elementary chemical reactions proceeding at finite rates revisited using Lyapunov function analysis. Energy. 2005;30(6):897–913.

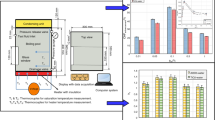

Wenhao W, Fuzhong W, Qingbo Y, Huixin J. Experimental investigation of titanium tetrachloride in pool boiling heat transfer. Int J Heat Mass Transf. 2018;122:1308–12. https://doi.org/10.1016/j.ijheatmasstransfer.2018.02.051.

Dikici B, Eno E, Compere M. Pool boiling enhancement with environmentally friendly surfactant additives. J Therm Anal Calorim. 2014;116(3):1387–94.

Akar S, Rashidi S, Esfahani JA. Second law of thermodynamic analysis for nanofluid turbulent flow around a rotating cylinder. J Therm Anal Calorim. 2017;4:1–12.

Wenhao W, Fuzhong W, Huixin J. Enhancement and performance evaluation for heat transfer of air cooling zone for reduction system of sponge titanium. Heat Mass Transfer. 2017;53(2):465–73. https://doi.org/10.1007/s00231-016-1836-z.

Bornhorst WJ, Hatsopoulos GN. Analysis of a liquid vapor phase change by the methods of irreversible thermodynamics. J Appl Mech. 1967;34(4):840–6. https://doi.org/10.1115/1.3607845.

Amin A. Enthalpy of vaporization, its temperature dependence and correlation with surface tension: a theoretical approach. Fluid Phase Equilibr. 2017;432:62–9.

Chervonyj I, Listopad D. Thermodynamic laws of impurities in the titanium sponge inflow during its production. Acta Mechanica Slovaca. 2009;13(4):40–7. https://doi.org/10.2478/v10147-010-0035-z.

Ward CA, Stanga D. Interfacial conditions during evaporation or condensation of water. Phys Rev E. 2001;64(051509):1–9. https://doi.org/10.1103/physreve.64.051509.

Rahimi P, Ward CA. Effect of pressure on the rate of evaporation from capillaries: statistical rate theory approach. Int J Heat Mass Transf. 2004;47(5):877–86.

Acknowledgements

This research was supposed by the National Natural Science Foundation of China (NO. 51574094), the Science and Technology Department of Guizhou Province under grant number 3009 in 2013, 4002 in 2014 and 2004 in 2014. And all co-authors thank the reviewers for the valuable comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W., Wu, F., Yu, Q. et al. Interfacial liquid–vapor phase change and entropy generation in pool boiling experiment for titanium tetrachloride. J Therm Anal Calorim 133, 1571–1578 (2018). https://doi.org/10.1007/s10973-018-7203-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7203-1