Abstract

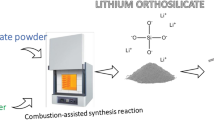

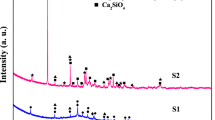

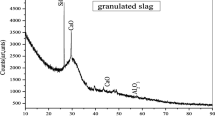

Blast furnace slag was leached using HCl to prepare lithium-based sorbents for CO2 capture, and chemical composition and phase of the acid leaching slag were determined by X-ray fluorescence analysis. The microstructure and morphology of both sorbents were characterized by scanning electron microscope and X-ray diffraction. The absorption capacity of both sorbents was observed non-isothermally and isothermally using thermogravimetric analysis, and 12 carbonation and calcination cycles were conducted to observe cycling stability. Controlling step of absorption process was determined by fitting the isothermal graphs using a double exponential model. The results show that 98.33% amorphous SiO2 can be obtained when the blast furnace slag was treated at 373 K for 10 h. Purified lithium-based sorbent by acid leaching slag (LBS-ALS) shows dense polyhedral particles with particle size between 25 and 120 μm. LBS-ALS shows similar absorption capacity with pure Li4SiO4 (P-Li4SiO4), but narrower absorption temperature range at non-isothermal absorption condition. The double exponential model fits well with the isothermal graphs for LBS-ALS and P-Li4SiO4, and diffusion of CO2 is the controlling step of the absorption process at lower temperature. LBS-ALS shows different controlling mechanism for desorption process compared with P-Li4SiO4. LBS-ALS maintains higher absorption capacity after 12 cycles in 100% CO2 flow.

Similar content being viewed by others

References

VandenBerg AWC, Arean CO. Materials for hydrogen storage: current research trends and perspectives. Chem Commun. 2008;2008:668–81.

IEA. Energy technology perspectives 2010-scenarios and strategies to 2050, Paris, France; 2010. pp. 650–656.

Huitu K, Helle H, Helle M, et al. Optimization of steel making using fastmet direct reduced iron in the blast furnace. ISIJ Int. 2003;53:2038–46.

Dhunna R, Khanna R, Mansuri I, et al. Recycling waste bakelite as an alternative carbon resource for ironmaking applications. ISIJ Int. 2014;54:613–9.

Rui R, Duan W. Current situation of CO2 emission in iron and steel producing and its controlling methods. Sci Technol Rev. 2016;24:53–6.

Kittel J, Idem R, Gelowitz D, et al. Corrosion in MEA units for CO2 capture: pilot plant studies. Energy Proc. 2009;1:791–7.

McLarnon CR, Duncan JL. Testing of ammonia based CO2 capture with multi-pollutant control technology. Energy Proc. 2009;1:1027–34.

Wang X, Alvarado V, Swoboda-Colberg N, et al. Reactivity of dolomite in water-saturated supercritical carbon dioxide: significance for carbon capture and storage and for enhanced oil and gas recovery. Energy Convers Manage. 2013;65:564–73.

Pennline HW, Luebke DR, Jones KL, et al. Progress in carbon dioxide capture and separation research for gasification-based power generation point sources. Fuel Process Technol. 2008;89:897–907.

Gauer C, Heschel W. Doped lithium orthosilicate for absorption of carbon dioxide. J Mater Sci. 2006;41:2405–9.

Nakagawa K, Essaki K. CO2 absorption by lithium silicate at room temperature. J Chem Eng Jpn. 2004;6:772–90.

Bretado ME, Velderrain VG, Gutiérrez DL, et al. A new synthesis route to Li4SiO4 as CO2 catalytic/sorbent. Catal Today. 2005;107:863–7.

Nair BN, Burwood RP, Goh VJ, et al. Lithium based ceramic materials and membranes for high temperature CO2 separation. Prog Mater Sci. 2009;54:511–41.

Chowdhury MBI, Quddus MR, DeLasa HI. CO2 capture with a novel solid fluidizable sorbent: thermodynamics and temperature programmed carbonation–decarbonation. Chem Eng J. 2017;232:139–48.

Olivares-Marín M, Drage TC, Maroto-Valer MM. Novel lithium-based sorbents from fly ashes for CO2 capture at high temperatures. Int J Greenh Gas Control. 2010;4:623–9.

Venegas MJ, Fregoso-Israel E, Escamilla R, et al. Kinetic and reaction mechanism of CO2 sorption on Li4SiO4: study of the particle size effect. Ind Eng Chem Res. 2007;46:2407–12.

Ortiz-Landeros J, Gómez-Yáñez C, Palacios-Romero LM, et al. Structural and thermochemical chemisorption of CO2 on Li4+x(Si1–xAlx)O4 and Li4-x (Si1–xVx)O4 solid solutions. J Phys Chem. 2012;116:3163–71.

Ni J, Kawabe Y, Morishita M, et al. Improved electrochemical activity of LiMnPO4 by high-energy ball-milling. J Power Sources. 2011;196:8104–9.

Romero-Ibarra IC, Jortiz-Landeros J, Pfeiffer H. Microstructural and CO2 chemisorption analyses of Li4SiO4: effect of surface modification by the ball milling process. Thermochim Acta. 2013;567:118–24.

Xu Y, Zhang YZ, Hou LY, et al. Preparation of CaO–Al2O3–SiO2 system glass from molten blast furnace slag. Int J Min Metals Mater. 2014;21:169–74.

Kostura B, Kulveitová H, Leško J. Blast furnace slags as sorbents of phosphate from water solutions. Water Res. 2005;39:1795–802.

Adachi-Pagano M, Forano C. Synthesis of Al-rich hydrotalcite-like compounds by using the urea hydrolysis reaction?control of size and morphology. J Mater Chem. 2003;13:1988–92.

Li DL, Koike M, Chen JH, et al. Preparation of Ni–Cu/Mg/Al catalysts from hydrotalcite-like compounds for hydrogen production by steam reforming of biomass tar. Int J Hydrog Energy. 2014;39:10959–70.

Wang HY, Zhang JL, Wang GW, et al. Characteristics and kinetic analysis of co-combustion of brown coal and anthracite. J Therm Anal Calorim. 2016;126:447–54.

Feng Q, Lin Q, Gong F, et al. Adsorption of lead and mercury by rice husk ash. J Colloid Interface Sci. 2004;278:1–8.

Wang K, Guo X, Zhao P, et al. High temperature capture of CO2 on lithium-based sorbents from rice husk ash. J Hazard Mater. 2011;189:301–7.

Victoria L, Mejía-Trejo E, Fregoso-Israel H. Textural, structural, and CO2 chemisorption effects produced on the lithium orthosilicate by its doping with sodium(Li4-xNaxSiO4). Chem Mater. 2008;20:7171–6.

Liu W, Feng B, Wu Y, et al. Synthesis of sintering-resistant sorbents for CO2 capture. Environ Sci Technol. 2010;44:3093–7.

Steenari BM, Lindqvist O. High temperature reactions of straw ash and the anti-sintering additives kaolin and dolomite. Biomass Bioenergy. 1998;14:67–76.

Acknowledgements

The present work was supported by National Key Technology R&D Program (No. 2011BAC01B02).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Zhang, J., Wang, G. et al. High-temperature capture of CO2 by Li4SiO4 prepared with blast furnace slag and kinetic analysis. J Therm Anal Calorim 133, 981–989 (2018). https://doi.org/10.1007/s10973-018-7167-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7167-1