Abstract

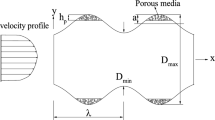

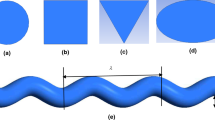

This paper investigates the combined effects of using nanofluid, a porous insert and corrugated walls on heat transfer, pressure drop and entropy generation inside a heat exchanger duct. A series of numerical simulations are conducted for a number of pertinent parameters. It is shown that the waviness of the wall destructively affects the heat transfer process at low wave amplitudes and that it can improve heat convection only after exceeding a certain amplitude. Further, the pressure drop in the duct is found to be strongly influenced by the wave amplitude in a highly non-uniform way. The results, also, show that the second law and heat transfer performances of the system improve considerably by thickening the porous insert and decreasing its permeability. Yet, this is associated with higher pressure drops. It is argued that the hydraulic, thermal and entropic behaviours of the system are closely related to the interactions between a vortex formation near the wavy walls and nanofluid flow through the porous insert. Viscous irreversibilities are shown to be dominant in the core region of duct where the porous insert is placed. However, in the regions closer to the wavy walls, thermal entropy generation is the main source of irreversibility. A number of design recommendations are made on the basis of the findings of this study.

Similar content being viewed by others

Abbreviations

- α :

-

Amplitude of wave (m)

- C F :

-

Forchheimer coefficient (–)

- C p :

-

Specific heat at constant pressure (J kg−1 K−1)

- Da :

-

Darcy number (–) \( \left( {Da = \frac{K}{{H^{2} }}} \right) \)

- f :

-

Friction factor (–)

- h :

-

Heat transfer coefficient (W m−2 K−1)

- H :

-

Average distance between corrugated walls (m)

- H P :

-

Porous layer thickness (m)

- k :

-

Thermal conductivity (W m−1 K−1)

- K :

-

Permeability of porous material (m2)

- L :

-

Heater length (m)

- L w :

-

Wavelength of the corrugated walls (m)

- N :

-

Dimensionless average entropy generation rate (–)

- N g :

-

Dimensionless local volumetric entropy generation rate (–)

- Nu :

-

Nusselt number (–)

- p :

-

Pressure (Pa)

- P :

-

Non-dimensional pressure

- R k :

-

Thermal conductivity ratio (–)

- Re :

-

Reynolds number (–)

- S :

-

Dimensionless porous layer thickness (–)\( \left( {S = \frac{{H_{P} }}{H}} \right) \)

- S gen :

-

Local volumetric entropy generation rate (W m−3 K−1)

- T :

-

Temperature (K)

- u, v :

-

Velocity component in x and y directions, respectively (ms−1)

- U, V :

-

Non-dimensional velocity components (–)

- U in :

-

Inlet velocity (ms−1)

- x, y :

-

Rectangular coordinates components (m)

- X, Y :

-

Non-dimensional rectangular coordinates components (–)

- α :

-

Non-dimensional wave amplitude (–) \( \left( {\alpha = \frac{a}{H}} \right) \)

- \( \varepsilon \) :

-

Porosity (–)

- \( \Delta P^{*} \) :

-

Dimensionless pressure drop (–) \( \left( {\Delta P^{*} = \frac{\Delta P}{{\rho U_{\text{in}}^{2} }}} \right) \)

- \( \mu \) :

-

Dynamic viscosity (kg m−1 s−1)

- \( \nu \) :

-

Kinematic viscosity (m2 s−1)

- \( \theta \) :

-

Dimensionless temperature (–)

- \( \rho \) :

-

Density of the fluid (kg m−3)

- \( \varphi \) :

-

Volume fraction of nanoparticles

- ave :

-

Average value

- eff :

-

Effective

- nf :

-

Nanofluid

- in :

-

Inlet

- w :

-

Wall

- x:

-

Local value

References

Tian Y, Zhao CY. A review of solar collectors and thermal energy storage in solar thermal applications. Appl Energy. 2013;104:538–53.

Bisht VS, Patil AK, Gupta A. Review and performance evaluation of roughened solar air heaters. Renew Sust Energ Rev. 2018;81:954–77.

Thakur DS, Khan MK, Pathak M. Solar air heater with hyperbolic ribs: 3D simulation with experimental validation. Renew Energ. 2017;113:357–68.

Rashidi S, Esfahani JA, Rashidi A. A review on the applications of porous materials in solar energy systems. Renew Sust Energ Rev. 2017;73:1198–210.

Meibodi SS, Kianifar A, Mahian O, Wongwises S. Second law analysis of a nanofluid-based solar collector using experimental data. J Therm Anal Calorim. 2016;126:617–25.

Esfe MH, Behbahani PM, Arani AAA, Sarlak MR. Thermal conductivity enhancement of SiO2–MWCNT (85: 15%)–EG hybrid nanofluids. J Therm Anal Calorim. 2017;128:249–58.

Rashidi S, Mahian O, Languri EM. Applications of nanofluids in condensing and evaporating systems. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s10973-017-6773-7.

Menasria F, Zedairia M, Moummi A. Numerical study of thermohydraulic performance of solar air heater duct equipped with novel continuous rectangular baffles with high aspect ratio. Energy. 2017;133:593–608.

Saravanan A, Senthilkumaar JS, Jaisankar S. Performance assessment in V-trough solar water heater fitted with square and V-cut twisted tape inserts. Appl Therm Eng. 2016;102:476–86.

Priyam A, Chand P. Thermal and thermohydraulic performance of wavy finned absorber solar air heater. Sol Energy. 2016;130:250–9.

Milani Shivan K, Ellahi R, Mamourian M, Moghiman M. Effects of wavy surface characteristics on natural convection heat transfer in a cosine corrugated square cavity filled with nanofluid. Int J Heat Mass Transf. 2017;107:1110–8.

Ellahi R, Tariq MH, Hassan M, Vafai K. On boundary layer nano-ferroliquid flow under the influence of low oscillating stretchable rotating disk. J Mol Liq. 2017;229:339–45.

Milani Shirvan K, Mamourian M, Mirzakhanlari S, Ellahi R. Numerical investigation of heat exchanger effectiveness in a double pipe heat exchanger filled with nanofluid: a sensitivity analysis by response surface methodology. Powder Technol. 2017;313:99–111.

Hassan M, Zeeshan A, Majeed A, Ellahi R. Particle shape effects on ferrofuids flow and heat transfer under influence of low oscillating magnetic field. J Magn Magn Mater. 2017;443:36–44.

Ijaz N, Zeeshan A, Bhatti MM, Ellahi R. Analytical study on liquid-solid particles interaction in the presence of heat and mass transfer through a wavy channel. J Mol Liq. 2018;250:80–7.

Ellahi R, Hassan M, Zeeshan A, Khan AA. The shape effects of nanoparticles suspended in HFE-7100 over wedge with entropy generation and mixed convection. App Nanosci. 2016;6:641–51.

Ellahi R, Hassan M, Zeeshan A. Aggregation effects on water base Al2O3—nanofluid over permeable wedge in mixed convection. Asia-Pac J Chem Eng. 2016;11:179–86.

Ellahi R, Zeeshan A, Hassan M. Particle shape effects on Marangoni convection boundary layer flow of a nanofluid. Int. J. Numer. Methods Heat Fluid Flow. 2016;26:2160-2174.

Sheikholeslami M, Zaigham Zia QM, Ellahi R. Influence of induced magnetic field on free convection of nanofluid considering Koo-Kleinstreuer-Li (KKL) correlation. Appl Sci. 2016;6:1–11.

Akbarzadeh M, Rashidi S, Bovand M, Ellahi R. A sensitivity analysis on thermal and pumping power for the flow of nanofluid inside a wavy channel. J Mol Liq. 2016;220:1–13.

Ganji DD, Malvandi A. Heat transfer enhancement using nanofluid flow in microchannels: simulation of heat and mass transfer. William Andrew, 2016.

Hussein AM, SharmaKV, Bakar RA, Kadirgama K. A review of forced convection heat transfer enhancement and hydrodynamic characteristics of a nanofluid. Renew Sust Energ Rev. 2014;29:734-743.

Wu JM, Zhao J. A review of nanofluid heat transfer and critical heat flux enhancement—research gap to engineering application. Prog Nucl Energ. 2013;66:13–24.

Michael JJ, Iniyan S. Performance of copper oxide/water nanofluid in a flat plate solar water heater under natural and forced circulations. Energ Convers Manage. 2015;95:160–9.

Bovand M, Rashidi S, Ahmadi G, Esfahani JA. Effects of trap and reflect particle boundary conditions on particle transport and convective heat transfer for duct flow - A two-way coupling of Eulerian-Lagrangian model. Appl Therm Eng. 2016;108:368–77.

Nield D, Bejan A. Convection in porous media. springer, New York, 2017.

Shokouhmand H, Jam F, Salimpour MR. The effect of porous insert position on the enhanced heat transfer in partially filled channels. Int Commun Heat Mass Transf. 2011;38:1162–7.

Maerefat M, Mahmoudi SY, Mazaheri K. Numerical simulation of forced convection enhancement in a pipe by porous inserts. Heat Transfer Eng. 2011;32:45–56.

Torabi M, Karimi N, Zhang K. Heat transfer and second law analyses of forced convection in a channel partially filled by porous media and featuring internal heat sources. Energy. 2015;93:106–27.

Karimi N, Agbo D, Talat Khan A, Younger PL. On the effects of exothermicity and endothermicity upon the temperature fields in a partially-filled porous channel. Int J Therm Sci. 2015;96:128–48.

Dickson C, Torabi M, Karimi N. First and second law analysis of nanofluid convection through a porous channel-The effects of partial filling and internal heat sources. Appl Therm Eng. 2016;103:459–80.

Torabi M, Dickson C, Karimi N. Theoretical investigation of entropy generation and heat transfer by forced convection of copper-water nanofluid in a porous channel- Local thermal non-equilibrium and partial filling effects. Powder Technol. 2016;301:234–54.

Siavashi M, Talesh Bahrami HR, Saffari H. Numerical investigation of flow characteristics, heat transfer and entropy generation of nanofluid flow inside an annular pipe partially or completely filled with porous media using two-phase mixture model. Energy. 2015;93:2451–66.

Mahmud S, Das PK, Hyder N, Sadrul Islam AKM. Free convection in an enclosure with vertical wavy walls. Int J Therm Sci. 2002;41:440–6.

Mahmud S, Sadrul Islam AKM. Laminar free convection and entropy generation inside an inclined wavy enclosure. Int J Therm Sci. 2003;42:1003–12.

Mahmud S, Fraser RA. Free convection and entropy generation inside a vertical inphase wavy cavity. Int Commun Heat Mass Transf. 2004;31:455–66.

Rush TA, Newell TA, Jacobi AM. An experimental study of flow and heat transfer in sinusoidal wavy passages. Int J Heat Mass Transf. 1999;42:1541–53.

Wang CC, Chen CK. Forced convection in a wavy-wall channel. Int J Heat Mass Transf. 2002;45:2587–95.

Castellões FV, Quaresma JNN, Cotta RM. Convective heat transfer enhancement in low Reynolds number flows with wavy walls. Int J Heat Mass Transf. 2010;53:2022–34.

Heidary H, Kermani MJ. Effect of nano-particles on forced convection in sinusoidal-wall channel. Int Commun Heat Mass Trans. 2010;37:1520–7.

Heidary H, Kermani MJ. Heat transfer enhancement in a channel with block(s) effect and utilizing Nano-fluid. Int J Therm Sci. 2012;57:163–71.

Rashidi MM, Hosseini A, Pop I, Kumar S, Freidoonimehr N. Comparative numerical study of single and two-phase models of nanofluid heat transfer in wavy channel. Appl Math Mech-Engl. 2014;35:831–48.

Ahmed MA, Shuai NH, Yusoff MZ. Numerical investigations on the heat transfer enhancement in a wavy channel using nanofluid. Int J Heat Mass Transf. 2012;55:5891–8.

Torabi M, Zhang K, Karimi N, Peterson GP. Entropy generation in thermal systems with solid structures-a concise review. Int J Heat Mass Transf. 2016;97:917–31.

Torabi M, Karimi N, Peterson GP. Challenges and progress on modeling of entropy generation in porous media: a review. Int J Heat Mass Transf. 2017;114:31–46.

Mahian O, Kianifar A, Kleinstreuer C, Al-Nimr MA, Pop I, Sahin AZ, Wongwises S. A review of entropy generation in nanofluid flow. Int J Heat Mass Transf. 2013;65:514–32.

Ko TH. Numerical analysis of entropy generation and optimal Reynolds number for developing laminar forced convection in double-sine ducts with various aspect ratios. Int J Heat Mass Transf. 2006;49:718–26.

Esfahani JA, Akbarzadeh M, Rashidi S, Rosen MA, Ellahi R. Influences of wavy wall and nanoparticles on entropy generation over heat exchanger plate. Int J Heat Mass Transf. 2017;109:1162–71.

Albojamal A, Vafai K. Analysis of single phase, discrete and mixture models, in predicting nanofluid transport. Int J Heat Mass Transf. 2017;114:225–37.

Givler RC, Altobelli SA. A determination of the effective viscosity for the Brinkmane-Forchheimer flow model. J Fluid Mech. 1994;258:355–70.

Yang C, Nakayama A, Liu W. Heat transfer performance assessment for forced convection in a tube partially filled with a porous medium. Int J Therm Sci. 2012;54:98–108.

Lee DY, Vafai K. Analytical characterization and conceptual assessment of solid and fluid temperature differentials in porous media. Int J Heat Mass Transf. 1999;42:423–35.

Minkowycz WJ, Haji-Sheikh A, Vafai K. On departure from local thermal equilibrium in porous media due to a rapidly changing heat source: the Sparrow number. Int J Heat Mass Transf. 1999;42:3373–85.

Valipour MS, Masoodi R, Rashidi S, Bovand M, Mirhosseini M. A numerical study on convection around a square cylinder using Al2O3-H2O nanofluid. Therm Sci. 2014;18:1305–14.

Zhou SQ, Ni R. Measurement of the specific heat capacity of water-based Al2O3 nanofluid. Appl Phys Lett. 2008;92:093123.

Masoumi N, Sohrabi N, Behzadmehr A. A new model for calculating the effective viscosity of nanofluids. J Phys D Appl Phys. 2009;42:055501.

Chon CH, Kihm KD, Lee SP, Choi SU. Empirical correlation finding the role of temperature and particle size for nanofluid (Al2O3) thermal conductivity enhancement. Appl Phys Lett. 2005;87:153107.

Patankar SV. Numerical heat transfer and fluid flow. New York: Hemisphere; 1980.

Ahmed MA, Yusoff MZ, Ng KC, Shuaib NH. Numerical and experimental investigations on the heat transfer enhancement in corrugated channels using SiO2-water nanofluid. Case Studies in Thermal Engineering. 2015;6:77–99.

Dukhan N, Bagcı O, Ozdemir M. Thermal development in open-cell metal foam: an experiment with constant wall heat flux. Int J Heat Mass Transf. 2015;85:852–9.

Acknowledgements

N. Karimi acknowledges the financial support by EPSRC through Grant No. EP/N020472/1 (Therma-pump).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akbarzadeh, M., Rashidi, S., Karimi, N. et al. First and second laws of thermodynamics analysis of nanofluid flow inside a heat exchanger duct with wavy walls and a porous insert. J Therm Anal Calorim 135, 177–194 (2019). https://doi.org/10.1007/s10973-018-7044-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7044-y