Abstract

Commercial cast iron is a typical multi-phase, natural metal matrix composite, including a ferrous matrix at different alloying grade and several phases, each having varying levels of carbon and other elements present, such as carbide, graphite and nitride. It was found that some active elements, such as S, O, Al, Ca, Ba and RE (rare earth), are important to control carbide/graphite phase formation. A major purpose of the present paper was to investigate the solidification pattern and structure of un-inoculated and inoculated cast irons, with intentionally critical conditions for graphite nucleation, typical for electric melted iron, by thermal (cooling curve) analysis technique; this is especially pertinent to the production of thin section iron castings. Increased chill (carbides formation), undercooled graphite amount, eutectic cells count and relative density correlate well with the degree of eutectic undercooling, at the beginning of eutectic reaction and at the end of solidification. Inoculation application led to decrease of ∆Tm and increase of ∆T1 (it became positive) and ∆T3 (less negative) parameters, at higher influencing power on ∆T1 parameter (narrow variation range). Higher inoculant addition rate gives better cooling curve analysis parameters. ∆T1 appears to be the recommended cooling curve analysis parameter to characterize the specifics of solidification pattern and structure formation on the entire solidification range.

Similar content being viewed by others

References

Riposan I, Chisamera M, Stan S. New developments in high quality grey cast irons. China Foundry. 2014;11(4):351–64.

Riposan I, Skaland T. Modification and Inoculation of Cast Iron. In: In D.M. Stefanescu, Volume Editor, Cast Iron Science and Technology Handbook. 2017. pp. 160–176, American Society of Materials.

Sparkman D, Bhaskaram CA. Chill measurement by thermal analysis. AFS Trans. 1996;104:969–76.

Sillen, RV. Optimizing Inoculation Practice by means of Thermal Analysis. In: AFS International Inoculation Conference, 6–8 Apr.1998, Rosemont, Illinois,USA.

Dioszegi A, Hattel J. Inverse thermal analysis method to study solidification in cast iron. Int J Cast Met Res. 2004;17(5):311–8.

Emadi D, Whiting LV, Nafisi S, Ghomashchi R. Applications of thermal analysis in quality control of solidification processes. J Therm Anal Calorim. 2005;81:235–42.

Dioszegi A, Svensson IL. On the problems of thermal analysis of solidification. Mater Sci Eng A. 2005;413–414:474–9.

Sillen RV. Novacast Technologies, www.novacast.se, 2006.

Chisamera M, Stan S, Riposan I, Costache G, Barstow M. Solidification pattern of in-mold and ladle inoculated low sulfur hypoeutectic gray cast irons. AFS Trans. 2008;116:641–52.

Stan S, Chisamera M, Riposan I, Stefan E, Barstow M. Solidification pattern of un-inoculated and inoculated gray cast irons in wedge test samples. AFS Trans. 2010;118:295–309.

Sparkman D. Microstructure by Thermal Analysis. AFS Trans. 2011; Paper 11-068:413–419.

Stan S, Chisamera M, Riposan I, Barstow M. Applications of thermal analysis to monitor the quality of hypoeutectic cast irons during solidification in sand and metal moulds. J Therm Anal Calorim. 2012;110(3):1185–92.

Stefanescu DM, Moran M, Boonmee S. The use of combined liquid displacement and cooling curve analysis in understanding the solidification of cast iron. AFS Trans. 2012;120:365–74.

Riposan I, Chisamera M, Stan S, Barstow M. Identifying chill tendency of cast iron melts by thermal analysis. Int J Cast Met Res. 2013;26(3):152–9.

Alonso G, Stefanescu DM, Suarez R. Understanding graphite expansion during the eutectic solidification of cast iron through combined linear displacement and thermal analysis. Int Foundry Res. 2014;66(4):2–12.

Riposan I, Stefan IC, Firican MC, Stan S. Thermal Analysis to Optimize and Control the Cast Iron Solidification Process. In: Proc 6th Int Conf. Advanced Materials and Structures–AMS ‘13, 16–17 Oct. 2015, Timisoara, Romania.

Stefanescu DM. Thermal analysis-theory and applications in metalcasting. J Metalcasting. 2015;9(1):7–22.

Klancnik U, Habjan J, Klancnik G, Medved J. Thermal analysis of indefinite chill cast iron modified with ferrovanadium and ferrotungsten. J Therm Anal Calorim. 2017;127:71–8.

Tadesse A, Fredriksson H. Volume change during the solidification of grey cast iron: its relation with the microstructural variation, comparison between experimental and theoretical analysis. Int J Cast Met Res. 2017. https://doi.org/10.1080/13640461.2016.1277851.

Chisamera M, Riposan I, Stan S, Skaland T. Effects of calcium and strontium undercooling, chill and microstructure in grey irons of varying sulphur and oxygen contents. In: Proc. 64th World Foundry Congress, 2000, Paris, France, Paper No. 62.

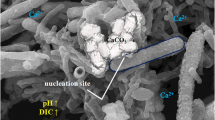

Riposan I, Chisamera M, Stan S, Skaland T, Onsoien MI. Analyses of possible nucleation sites in Ca/Sr overinoculated grey irons. AFS Trans. 2001;109:1151–62.

Riposan I, Chisamera M, Stan S, SkalandT. Graphite nucleants (microinclusions) characterization in Ca/Sr inoculated grey irons. Int J Cast Metal Res. 2003; 16(1–3):105–111.

Riposan I, Chisamera M, Stan S, Toboc P, Ecob C, White D. Al, Zr-FeSi preconditioning of grey cast irons. Mater Sci Technol. 2008;24(5):579–84.

Chisamera M, Riposan I, Stan S, White D, Grasmo G. Graphite nucleation control in grey cast iron. Int J Cast Metal Res. 2008;21(1–4):39–44.

Sommerfeld A, Tonn B. Nucleation of graphite in cast iron melts depending on manganese, sulphur and oxygen. Int J Cast Met Res. 2008;21(1–4):23–6.

Gundlach R. observations on structure control to improve the properties of cast irons. The honorary cast iron lecture, Div.5, 112nd AFS Metalcasting Congress, Atlanta, Georgia, USA; 2008. Paper 08–158.

Riposan I, Chisamera M, Stan S, Ecob C, Wilkinson D. Role of Al, Ti, Zr in Grey Iron Preconditioning/Inoculation. J Mater Eng Perform. 2009;18(1):83–7.

Sommerfeld A, Tonn B. Theory of graphite nucleation in lamellar graphite cast iron. Int. J. Metalcasting. 2009;3(4):39–47.

Campbell JA. Hypothesis for cast iron microstructures. Met Mater Trans B. 2009;40(6):786–801.

Riposan I, Chisamera M, Stan S, Hartung C, White D. Three-stage model for nucleation of graphite in grey cast iron. Mater Sci Technol. 2010;26(12):1439–47.

Elmquist L, Salera S, Dioszegi A. Inoculation and its effect on primary solidification structure of hypoeutectic grey cast iron. Int J Cast Met Res. 2010;23(2):124–9.

Riposan I, Chisamera M, Stan S. Enhanced quality in electric melt grey cast irons. ISIJ Int. 2013;53(10):1683–95.

Alonso G, Stefanescu DM, Larranaga P, De la Fuente F, Suarez R. On the Nucleation of Graphite in Lamellar Graphite Cast Iron. AFS Trans. 2016; 124:Paper 16–020.

American Society for Testing of Materials, Standard A367–85: Standard Test Methods of Chill Testing of Cast Iron, 1. West Conshohocken. USA: PA; 2000. p. 151–4.

Riposan I, Chisamera M, Stan S, White D. Chilling properties of Ba/Ca/Sr inoculated grey cast irons. Int J Cast Met Res. 2007;20(2):90–7.

Acknowledgements

This work was partially financed by a grant of the Romanian National Authority for Scientific Research and Innovation, CNCS/CCCDI–UEFISCDI, project number PN-III-P2-2.1-PED-2016-1793, within PNCDI III.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Riposan, I., Chisamera, M. & Stan, S. Application of cooling curve analysis in solidification pattern and structure control of grey cast irons. J Therm Anal Calorim 132, 1017–1028 (2018). https://doi.org/10.1007/s10973-018-7023-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7023-3