Abstract

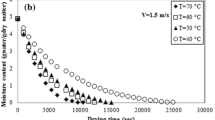

The effects of air temperature and relative humidity (RH) on the drying kinetics of two kinds of flue-cured tobacco strips (C3F and B3F) were studied using a thermogravimetric device in this work. The drying experiments were carried out with drying air temperatures of 60, 70, 80, and 90 °C and RH values of 0, 10, 20, 30, and 40% at a constant airflow. Taking the effect of RH into consideration, a modified Arrhenius-type equation of diffusivity was proposed. In addition, comparing five thin-layer drying models and five equilibrium moisture content models to describe the drying kinetics and the desorption isotherms of tobacco strips, high coefficients of determination (R2) and low reduced Chi-square (χ2) and residual sum of squares (RSS) values indicated that the Logarithmic model and the Modified Oswin model appeared to be the most suitable for predicting the moisture ratio and the moisture desorption relationship of tobacco strips. The effective moisture diffusion coefficient under different temperatures and RHs ranged from 1.68 × 10−11 to 6.81 × 10−11 m2 s−1 for C3F and from 1.62 × 10−11 to 6.68 × 10−11 m2 s−1 for B3F. A modified Arrhenius-type equation with an RH term was found to be effective for describing the drying behavior of two flue-cured tobacco strips, and the activation energy (Ea) values were 34.6 and 35.2 kJ mol−1 for C3F and B3F, respectively.

Similar content being viewed by others

Abbreviations

- A :

-

Model constant (−)

- a, b, c, k, n :

-

Model constant (−)

- B 1 :

-

Constant (m2 s−1)

- B 2 :

-

Constant (%−1)

- D eff :

-

Effective diffusion coefficient of moisture (m2 s−1)

- DR:

-

Drying rate (dry basis) (g water g−1 s−1)

- E a :

-

Activation energy (kJ mol−1)

- L :

-

Average thickness of tobacco strips (m)

- MR:

-

Moisture ratio (−)

- MRexp,i :

-

The i-th experimental moisture ratio (−)

- MRpre,i :

-

The i-th predicted moisture ratio (−)

- N :

-

Number of observations (−)

- n :

-

Number of constants (−)

- R :

-

Gas constant (J mol−1 K−1)

- R 2 :

-

Coefficient of determination (−)

- RSS:

-

Residual sum of squares (−)

- RH:

-

Relative humidity (%)

- T :

-

Temperature (°C)

- t :

-

Time (s)

- X :

-

Moisture content (dry basis) (g water g−1)

- χ 2 :

-

Reduced Chi-square (−)

- 0:

-

Initial value

- e:

-

Equilibrium

References

Wang H, Xin H, Liao Z, Li J, Xie W, Zeng Q, et al. Study on the effect of cut tobacco drying on the pyrolysis and combustion properties. Dry Technol. 2014;32(2):130–4.

Toğrul İT, Pehlivan D. Modelling of thin layer drying kinetics of some fruits under open-air sun drying process. J Food Eng. 2004;65(3):413–25.

Kayran S, Doymaz İ. Determination of drying kinetics and physicochemical characterization of apricot pomace in hot-air dryer. J Therm Anal Calorim. 2017;130(2):1163–70. https://doi.org/10.1007/s10973-017-6504-0.

Krokida MK, Karathanos VT, Maroulis ZB, Marinos-Kouris D. Drying kinetics of some vegetables. J Food Eng. 2003;59(4):391–403.

Huang YW, Chen MQ. Thin-layer isothermal drying kinetics of municipal sewage sludge based on two falling rate stages during hot-air-forced convection. J Therm Anal Calorim. 2017;129(1):567–75. https://doi.org/10.1007/s10973-017-6150-6.

Hosseinabadi HZ, Doosthoseini K, Layeghi M. Drying kinetics of poplar (populus deltoides) wood particles by a convective thin layer dryer. Drvna Ind. 2012;63(3):169–76.

Esturk O. Intermittent and continuous microwave-convective air-drying characteristics of sage (Salvia officinalis) leaves. Food Bioprocess Technol. 2012;5(5):1664–73.

Roberts JS, Kidd DR, Padilla-Zakour O. Drying kinetics of grape seeds. J Food Eng. 2008;89(4):460–5.

Alvarez-López I, Llanes-Santiago O, Verdegay JL. Drying process of tobacco leaves by using a fuzzy controller. Fuzzy Set Syst. 2005;150(3):493–506.

Martínezmartínez V, Baladrón C, Gomezgil J, Ruizruiz G, Navasgracia LM, Aguiar JM, et al. Temperature and relative humidity estimation and prediction in the tobacco drying process using artificial neural networks. Sens Basel. 2012;12(10):14004–21.

Kiranoudis CT, Maroulis ZB, MarinosKouris D. Mass transfer modeling for virginia tobacco curing. Dry Technol. 1990;8(2):351–66.

Legros R, Millington CA, Clift R. Drying of tobacco particles in a mobilized bed. Dry Technol. 1994;12(3):517–43.

Zhu WK, Wang L, Duan K, Chen LY, Li B. Experimental and numerical investigation of the heat and mass transfer for cut tobacco during two-stage convective drying. Dry Technol. 2015;33(8):907–14.

Liu JT, Li M, Yu QF, Ling DL. A novel parabolic trough concentrating solar heating for cut tobacco drying system. Int J Photoenergy. 2014;2014:1–10.

Huang F, Chen Q, Wang L, Dou J, Wang S, Li B. Study on thin-layer dynamic models of humidifying and drying of tobacco strips. Acta Tabacaria Sin. 2014;20(6):34–40 (in Chinese).

Xu D, Dai Y, Jin D, Zhu W, Du J. Effects of drying conditions on rehydration characteristics of tobacco strips. Tob Sci Technol. 2013(4):5–8 + 15(in Chinese).

Bispo JAC, Bonafe CFS, Santana KMOV, Santos ECA. A comparison of drying kinetics based on the degree of hydration and moisture ratio. LWT Food Sci Technol. 2015;60(1):192–8.

Bruce DM. Exposed-layer barley drying: three models fitted to new data up to 150 °C *. J Agric Eng Res. 1985;32(4):337–48.

Chen D-Y, Zhang D, Zhu X-F. Heat/mass transfer characteristics and non isothermal drying kinetics at the first stage of biomass pyrolysis. J Therm Anal Calorim. 2012;109(2):847–54. https://doi.org/10.1007/s10973-011-1790-4.

Babalis SJ, Papanicolaou E, Kyriakis N, Belessiotis VG. Evaluation of thin-layer drying models for describing drying kinetics of figs (Ficus Carica). J Food Eng. 2006;75(2):205–14.

Yaldiz O, Ertekin C, Uzun HI. Mathematical modeling of thin layer solar drying of Sultana grapes. Energy. 2001;26(5):457–65.

Heras ML, Heredia A, Castelló ML, Andrés A. Moisture sorption isotherms and isosteric heat of sorption of dry persimmon leaves. Food Biosci. 2014;7:88–94.

Raji AO, Ojediran JO. Moisture sorption isotherms of two varieties of millet. Food Bioprod Process. 2011;89(3):178–84.

Kaymak-Ertekin F, Gedik A. Sorption isotherms and isosteric heat of sorption for grapes, apricots, apples and potatoes. LWT Food Sci Technol. 2004;37(4):429–38.

Halsey G. Physical adsorption on non-uniform surfaces. J Chem Phys. 1948;16(10):931–7.

Mehta S, Singh A. Adsorption isotherms for red chilli (Capsicum annum L.). Eur Food Res Technol. 2006;223(6):849–52.

Zhang JW, Xin YN, Li B. Effects of temperature and humidity of drying medium on drying kinetics of strips. Tob Sci Technol. 2014;10:15–9 (in Chinese).

Tahmasebi A, Yu J, Han Y, Zhao H, Bhattacharya S. A kinetic study of microwave and fluidized-bed drying of a Chinese lignite. Chem Eng Res Des. 2013;92(1):54–65.

Queiroz MR, Nebra SA. Theoretical and experimental analysis of the drying kinetics of bananas. J Food Eng. 2001;47(2):127–32.

Crank J. The mathematics of diffusion. Oxford: Clarendon Press; 1975.

Bi J, Yang A, Liu X, Wu X, Chen Q, Wang Q, et al. Effects of pretreatments on explosion puffing drying kinetics of apple chips. LWT Food Sci Technol. 2015;60(2):1136–42.

Evin D. Thin layer drying kinetics of Gundelia tournefortii L. Food Bioprod Process. 2012;90(2):323–32.

Meziane S. Drying kinetics of olive pomace in a fluidized bed dryer. Enegy Convers Manag. 2011;52(52):1644–9.

Ait ML, Kouhila M, Jamali A, Lahsasni S, Mahrouz M. Moisture sorption isotherms and heat of sorption of bitter orange leaves (Citrus aurantium). J Food Eng. 2005;67(4):491–8.

Argyropoulos D, Alex R, Kohler R, Müller J. Moisture sorption isotherms and isosteric heat of sorption of leaves and stems of lemon balm (Melissa officinalis L.) established by dynamic vapor sorption. LWT Food Sci Technol. 2012;47(2):324–31.

Mghazli S, Idlimam A, Mahrouz M, Lahnine L, Hidar N, Ouhammou M, et al. Comparative moisture sorption isotherms, modelling and isosteric heat of sorption of controlled and irradiated Moroccan rosemary leaves. Ind Crop Prod. 2016;88:28–35.

He X, Lau AK, Sokhansanj S, Lim CJ, Bi XT, Melin S, et al. Moisture sorption isotherms and drying characteristics of aspen (Populus tremuloides). Biomass Bioenerg. 2013;57(10):161–7.

Horuz E, Bozkurt H, Karataş H, Maskan M. Drying kinetics of apricot halves in a microwave-hot air hybrid oven. Heat Mass Transf 2017;53(6):2117–27.

Beigi M. Hot air drying of apple slices: dehydration characteristics and quality assessment. Heat Mass Transf. 2016;52(8):1435–42.

Aghbashlo M, Kianmehr MH, Hassan-Beygi SR. Drying and rehydration characteristics of sour cherry (prunus cerasus l.). J Food Process Preserv. 2010;34(3):351–65.

Pusat S, Akkoyunlu MT, Erdem HH, Dağdaş A. Drying kinetics of coarse lignite particles in a fixed bed. Fuel Process Technol. 2015;130(130):208–13.

Inazu T, Iwasaki KI, Furuta T. Effect of temperature and relative Humidity on drying kinetics of fresh Japanese noodle (Udon). LWT Food Sci Technol. 2002;35(8):649–55.

Villeneuve S, Gélinas P. Drying kinetics of whole durum wheat pasta according to temperature and relative humidity. LWT Food Sci Technol. 2007;40(3):465–71.

Chen Q, Bi J, Wu X, Yi J, Zhou L, Zhou Y. Drying kinetics and quality attributes of jujube (Zizyphus jujuba Miller) slices dried by hot-air and short- and medium-wave infrared radiation. LWT Food Sci Technol. 2015;64(2):759–66.

Doymaz İ. Effect of pre-treatments using potassium metabisulphide and alkaline ethyl oleate on the drying kinetics of apricots. Biosyst Eng. 2004;89(3):281–7.

Toğrul İT, Pehlivan D. Modelling of drying kinetics of single apricot. J Food Eng. 2003;58(1):23–32.

Panchariya PC, Popovic D, Sharma AL. Thin-layer modelling of black tea drying process. J Food Eng. 2002;52(4):349–57.

Park KJ, Vohnikova Z, Fpr B. Evaluation of drying parameters and desorption isotherms of garden mint leaves (Mentha crispa L.). J Food Eng. 2002;51(3):193–9.

Kaleemullah S, Kailappan R. Drying kinetics of red chillies in a rotary dryer. Biosyst Eng. 2005;92(1):15–23.

Kaleemullah S, Kailappan R. Modelling of thin-layer drying kinetics of red chillies. J Food Eng. 2006;76(4):531–7.

Ortiz J, Lemus-Mondaca R, Vega-Gálvez A, Kong AH, Puente-Diaz L, Zura-Bravo L, et al. Influence of air-drying temperature on drying kinetics, colour, firmness and biochemical characteristics of Atlantic salmon (Salmo salar L.) fillets. Food Chem. 2013;139(1–4):162–9.

Demiray E, Tulek Y. Drying characteristics of garlic (Allium sativum L) slices in a convective hot air dryer. Heat Mass Transf. 2014;50(6):779–86.

Doymaz İ. Thin-layer drying characteristics of sweet potato slices and mathematical modelling. Heat Mass Transf. 2011;47(3):277–85.

Acknowledgements

The authors acknowledge the financial support of National Key Technology R&D Program of China (2015BAK39B02) and Fundamental Research Funds for the Central Universities (ZZ1327).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xin, Y.N., Zhang, J.W. & Li, B. Drying kinetics of tobacco strips at different air temperatures and relative humidities. J Therm Anal Calorim 132, 1347–1358 (2018). https://doi.org/10.1007/s10973-018-7005-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7005-5