Abstract

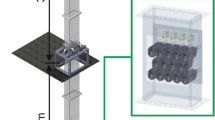

The objective of this paper is to investigate thermal efficiency enhancement methods in a linear Fresnel reflector (LFR) with evacuated tube receiver. The primary reflectors of the collector are flat mirrors of 27 m2 total net aperture, while the secondary reflector has a parabolic shape. The working fluid is Syltherm 800, and the analysis is performed for temperatures up to 650 K. The use of nanofluids and internal fins is the investigated thermal enhancement methods in the receiver of the LFR. The examined nanofluid is Syltherm/CuO for concentrations 2, 4 and 6%, while the examined internal fins are 8 longitudinal fins which are symmetrically located in the absorber. The LFR is examined using nanofluids and pure thermal oil in smooth or finned absorber. According to the final results, the maximum thermal efficiency enhancement is up to 1% and it is greater for higher operating temperature levels. The use of internal fins is better enhancement method compared to the use of nanofluids, while the combination of these two techniques leads to the highest possible performance. For the inlet temperature of 600 K with 200 L min−1 flow rate, the thermal efficiency enhancement with 4% nanofluid and finned absorber is found 0.82%, while it is found 0.61 and 0.28% with finned absorber with pure oil and 4% nanofluid with smooth absorber, respectively.

Similar content being viewed by others

Abbreviations

- A a :

-

Collector net area, m2

- C:

-

Concentration ratio

- c p :

-

Specific heat capacity under constant pressure, J kg−1 K-1

- D:

-

Diameter, m

- D m :

-

Distance between reflectors

- E :

-

Exergy, W

- F :

-

Focal length, m

- f :

-

Friction factor

- G b :

-

Solar direct beam irradiation, W m−2

- h :

-

Heat transfer coefficient, W m−2 K−1

- h out :

-

Convection coefficient between cover and ambient, W m−2 K−1

- k :

-

Thermal conductivity, W m−1 K−1

- L :

-

Tube length, m

- m:

-

Mass flow rate, kg s−1

- N rf :

-

Number of primary reflectors

- Nu :

-

Nusselt number

- PEC:

-

Performance evaluation criterion

- Pr :

-

Prandtl number

- p :

-

Fin length, mm

- Q :

-

Heat flux, W

- Re :

-

Reynolds number

- T :

-

Temperature, K

- T am :

-

Ambient temperature, K

- T 0 :

-

Reference temperature, K

- t :

-

Fin thickness, mm

- u :

-

Fluid velocity, m s−1

- V :

-

Volumetric flow rate, L min−1

- V wind :

-

Ambient air velocity, m s−1

- W :

-

Total width, m

- W p :

-

Pumping work, W

- W 0 :

-

Mirror width, m

- α :

-

Absorber absorbance

- β :

-

Ratio of the nanolayer thickness to the original particle radius

- γ :

-

Intercept factor

- ε :

-

Emittance

- ΔP :

-

Pressure drop, Pa

- η ex :

-

Exergy efficiency

- η opt :

-

Optical efficiency

- η th :

-

Thermal efficiency

- θ :

-

Solar incident angle, o

- μ :

-

Dynamic viscosity, Pa s

- ρ :

-

Density, kg m−3

- ρ 1 :

-

Primary concentrator reflectance

- ρ 2 :

-

Secondary concentrator reflectance

- τ :

-

Cover transmittance

- φ :

-

Nanoparticle volumetric concentration

- ω :

-

Peripheral absorber angle, o

- abs:

-

Absorbed

- bf:

-

Base fluid

- c:

-

Cover

- ci:

-

Inner cover

- co:

-

Outer cover

- fm:

-

Mean fluid

- in:

-

Inlet

- loss:

-

Thermal loss

- max:

-

Maximum

- nf:

-

Nanofluid

- np:

-

Nanoparticle

- opt:

-

Optical

- out:

-

Outlet

- r:

-

Receiver

- ri:

-

Inner receiver

- ro:

-

Outer receiver

- s:

-

Solar

- th:

-

Theoretical

- u:

-

Useful

- 0:

-

Reference case (smooth absorber and pure thermal oil)

- LFR:

-

Linear Fresnel reflector

- PTC:

-

Parabolic trough collector

References

Sokhansefat T, Kasaeian A, Rahmani K, Heidari AH, Aghakhani F, Mahian O. Thermoeconomic and environmental analysis of solar flat plate and evacuated tube collectors in cold climatic conditions. Renew Energy. 2018;115:501–8.

Fernandez AG, Galleguillos H, Fuentealba E, Perez FJ. Thermal characterization of HITEC molten salt for energy storage in solar linear concentrated technology. J Therm Anal Calorim. 2015;122(1):3–9.

Sabiha MA, Saidur R, Mekhilef S, Mahian O. Progress and latest developments of evacuated tube solar collectors. Renew Sustain Energy Rev. 2015;51:1038–54.

Abbas R, Martínez-Val JM. A comprehensive optical characterization of linear Fresnel collectors by means of an analytic study. Appl Energy. 2017;185(2):1136–51.

Palomba V, Brancato V, Frazzica A. Experimental investigation of a latent heat storage for solar cooling applications. Appl Energy. 2017;199:347–58.

Bellos E, Tzivanidis C, Symeou C, Antonopoulos KA. Energetic, exergetic and financial evaluation of a solar driven absorption chiller—a dynamic approach. Energy Convers Manag. 2017;131:34–48.

Loni R, Kasaeian AB, Askari Asli-Ardeh E, Ghobadian B. Optimizing the efficiency of a solar receiver with tubular cylindrical cavity for a solar-powered organic Rankine cycle. Energy. 2016;112:1259–72.

Montes MJ, Abbas R, Muñoz M, Muñoz-Antón J, Martínez-Val JM. Advances in the linear Fresnel single-tube receivers: hybrid loops with non-evacuated and evacuated receivers. Energy Convers Manag. 2017;49:318–33.

Montes MJ, Barbero R, Abbas R, Rovira A. Performance model and thermal comparison of different alternatives for the Fresnel single-tube receiver. Appl Therm Eng. 2016;104:162–75.

Morin G, Karl M, Mertins M, Selig M. Molten salt as a heat transfer fluid in a linear fresnel collector—commercial application backed by demonstration. Energy Proced. 2015;69:689–98.

Zhu G, Wendelin T, Wagner MJ, Kutscher C. History, current state, and future of linear Fresnel concentrating solar collectors. Sol Energy. 2014;103:639–52.

Boito P, Grena R. Optimization of the geometry of Fresnel linear collectors. Sol Energy. 2016;135:479–86.

Sharma V, Nayak JK, Kedare SB. Effects of shading and blocking in linear Fresnel reflector field. Sol Energy. 2015;113:114–38.

Benyakhlef S, Al Mers A, Merroun O, Bouatem A, Boutammachte N, El Alj S, Ajdad H, Erregueragui Z, Zemmouri E. Impact of heliostat curvature on optical performance of Linear Fresnel solar concentrators. Renew Energy. 2016;89:463–74.

Sahoo SS, Singh S, Banerjee R. Steady state hydrothermal analysis of the absorber tubes used in Linear Fresnel Reflector solar thermal system. Sol Energy. 2013;87:84–95.

Qiu Y, He Y-L, Wu M, Zheng Z-J. A comprehensive model for optical and thermal characterization of a linear Fresnel solar reflector with a trapezoidal cavity receiver. Renew Energy. 2016;97:129–44.

Qiu Y, Li M-J, Wang K, Liu Z-B, Xue X-D. Aiming strategy optimization for uniform flux distribution in the receiver of a linear Fresnel solar reflector using a multi-objective genetic algorithm. Appl Energy. 2017;205:1394–407.

Moghimi MA, Craig KJ, Meyer JP. Simulation-based optimisation of a linear Fresnel collector mirror field and receiver for optical, thermal and economic performance. Sol Energy. 2017;153:655–78.

Facão J, Oliveira AC. Numerical simulation of a trapezoidal cavity receiver for a linear Fresnel solar collector concentrator. Renew Energy. 2011;36(1):90–6.

Reddy KS, Kumar KR. Estimation of convective and radiative heat losses from an inverted trapezoidal cavity receiver of solar linear Fresnel reflector system. Int J Therm Sci. 2014;80:48–57.

Canavarro D, Chaves J, Collares-Pereira M. Simultaneous Multiple Surface method for Linear Fresnel concentrators with tubular receiver. Sol Energy. 2014;110:105–16.

Zhu G. New adaptive method to optimize the secondary reflector of linear Fresnel collectors. Sol Energy. 2017;144:117–26.

Prasad GSC, Reddy KS, Sundararajan T. Optimization of solar linear Fresnel reflector system with secondary concentrator for uniform flux distribution over absorber tube. Sol Energy. 2017;150:1–12.

Balaji S, Reddy KS, Sundararajan T. Optical modelling and performance analysis of a solar LFR receiver system with parabolic and involute secondary reflectors. Appl Energy. 2016;179:1138–51.

Canavarro D, Chaves J, Collares-Pereira M. A novel compound elliptical-type concentrator for parabolic primaries with tubular receiver. Sol Energy. 2016;134:383–91.

Grena R, Tarquini P. Solar linear Fresnel collector using molten nitrates as heat transfer fluid. Energy. 2011;36(2):1048–56.

Bellos E, Mathioulakis E, Tzivanidis C, Belessiotis V, Antonopoulos KA. Experimental and numerical investigation of a linear Fresnel solar collector with flat plate receiver. Energy Convers Manag. 2016;130:44–59.

Mathioulakis E, Papanicolaou E, Belessiotis V. Optical performance and instantaneous efficiency calculation of linear Fresnel solar collectors. Int J Energy Res. 2017;1–15. https://doi.org/10.1002/er.3925.

Pauletta S. A solar Fresnel collector based on an evacuated flat receiver. Energy Proced. 2016;101:480–7.

Lin M, Sumathy K, Dai YJ, Wang RZ, Chen Y. Experimental and theoretical analysis on a linear Fresnel reflector solar collector prototype with V-shaped cavity receiver. Appl Therm Eng. 2013;51(1–2):963–72.

Choi SU, Eastman J. Enhancing thermal conductivity of fluids with nanoparticles. Lemont: Argonne National Lab; 1995.

Bellos E, Tzivanidis C. Parametric investigation of nanofluids utilization in parabolic trough collectors. Therm Sci Eng Prog. 2017;2:71–9.

Mahian O, Kianifar A, Sahin AZ, Wongwises S. Entropy generation during Al2O3/water nanofluid flow in a solar collector: effects of tube roughness, nanoparticle size, and different thermophysical models. Int J Heat Mass Transf. 2014;78:64–75.

Bellos E, Tzivanidis C, Tsimpoukis D. Thermal, hydraulic and exergetic evaluation of a parabolic trough collector operating with thermal oil and molten salt based nanofluids. Energy Convers Manag. 2018;156(15):388–402.

Kaloudis E, Papanicolaou E, Belessiotis V. Numerical simulations of a parabolic trough solar collector with nanofluid using a two-phase model. Renew Energy. 2016;97:218–29.

Sokhansefat T, Kasaeian AB, Kowsary F. Heat transfer enhancement in parabolic trough collector tube using Al2O3/synthetic oil nanofluid. Renew Sustain Energy Rev. 2014;33:636–44.

Bellos E, Tzivanidis C, Antonopoulos KA, Gkinis G. Thermal enhancement of solar parabolic trough collectors by using nanofluids and converging-diverging absorber tube. Renew Energy. 2016;94:213–22.

Mwesigye A, Huan Z. Thermodynamic analysis and optimization of fully developed turbulent forced convection in a circular tube with water–Al2O3 nanofluid. Int J Heat Mass Transf. 2015;89:694–706.

Mwesigye A, Huan Z, Meyer JP. Thermodynamic optimisation of the performance of a parabolic trough receiver using synthetic oil–Al2O3 nanofluid. Appl Energy. 2015;156:398–412.

Kasaeian A, Daviran S, Azarian RD, Rashidi A. Performance evaluation and nanofluid using capability study of a solar parabolic trough collector. Energy Convers Manag. 2015;89:368–75.

Muñoz J, Abánades A. A technical note on application of internally finned tubes in solar parabolic trough absorber pipes. Sol Energy. 2011;85(3):609–12.

Muñoz J, Abánades A. Analysis of internal helically finned tubes for parabolic trough design by CFD tools. Appl Energy. 2011;88:4139–49.

Bellos E, Tzivanidis C, Daniil I. Energetic and exergetic investigation of a parabolic trough collector with internal fins operating with carbon dioxide. Int J Energy Environ Eng. 2017;8(2):109–22.

Bellos E, Tzivanidis C, Daniil I, Antonopoulos KA. The impact of internal longitudinal fins in parabolic trough collectors operating with gases. Energy Convers Manag. 2017;135:35–54.

Bellos E, Tzivanidis C, Tsimpoukis D. Thermal enhancement of parabolic trough collector with internally finned absorbers. Sol Energy. 2017;157:514–31.

Bellos E, Tzivanidis C, Tsimpoukis D. Multi-criteria evaluation of parabolic trough collector with internally finned absorbers. Appl Energy. 2017;205:540–61.

Too YCS, Benito R. Enhancing heat transfer in air tubular absorbers for concentrated solar thermal applications. Appl Therm Eng. 2013;50(1):1076–83.

Jaramillo OA, Borunda M, Velazquez-Lucho KM, Robles M. Parabolic trough solar collector for low enthalpy processes: an analysis of the efficiency enhancement by using twisted tape inserts. Renew Energy. 2016;93:125–41.

Bellos E, Tzivanidis C. Parametric analysis and optimization of an Organic Rankine Cycle with nanofluid based solar parabolic trough collectors. Renew Energy. 2017;114B:1376–93.

http://www.loikitsdistribution.com/files/syltherm-800-technical-data-sheet.pdf.

Bellos E, Tzivanidis C, Antonopoulos KA. A detailed working fluid investigation for solar parabolic trough collectors. Appl Therm Eng. 2017;114:374–86.

Bellos E, Tzivanidis C. A detailed exergetic analysis of parabolic trough collectors. Energy Convers Manag. 2017;149:275–92.

Petela R. Exergy of undiluted thermal radiation. Sol Energy. 2003;74(6):469–88.

Leinhard J IV, Leinhard J V. A heat transfer textbook. Cambridge: Phlogiston Press; 2012.

Pak BC, Cho YI. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf. 1998;11:151–70.

Mwesigye A, Huan Z, Meyer JP. Thermal performance of a receiver tube for a high concentration ratio parabolic trough system and potential for improved performance with Syltherm 800-CuO nanofluid. In: Proceedings of the ASME 2015 international mechanical engineering congress and exposition IMECE2015 November 13–19, 2015, Houston, Texas.

Loni R, Kasaeian AB, Mahian O, Sahin AZ. Thermodynamic analysis of an organic rankine cycle using a tubular solar cavity receiver. Energy Convers Manag. 2016;127:494–503.

Khanafer K, Vafai K. A critical synthesis of thermophysical characteristics of nanofluids. Int J Heat Mass Transf. 2011;54(19):4410–28.

Yu W, Choi SUS. The role of interfacial layers in the enhanced thermal conductivity of nanofluids: a renovated Maxwell model. J Nanopart Res. 2003;5:167.

Duangthongsuk W, Wongwises S. An experimental study on the heat transfer performance and pressure drop of TiO2-water nanofluids flowing under a turbulent flow regime. Int J Heat Mass Transf. 2010;53(1–3):334–44.

Batchelor GK. The effect of Brownian motion on the bulk stress in a suspension of spherical particles. J Fluid Mech. 1977;83:97–117.

SOLIDWORKS Flow Simulation 2015 Technical Reference.

Bellos E, Korres D, Tzivanidis C, Antonopoulos KA. Design, simulation and optimization of a compound parabolic collector. Sustain Energy Technol Assess. 2016;16:53–63.

Pavlović SR, Bellos E, Stefanović VP, Tzivanidis C, Stamenković ZM. Design, simulation and optimization of a solar dish collector spiral-coil thermal absorber. Thermal Sci. 2016;20(4):1387–97.

Tzivanidis C, Bellos E, Korres D, Antonopoulos KA, Mitsopoulos G. Thermal and optical efficiency investigation of a parabolic trough collector. Case Stud Therm Eng. 2015;6:226–37.

Bellos E, Tzivanidis C, Korres D, Antonopoulos KA. Thermal analysis of a flat plate collector with Solidworks and determination of convection heat coefficient between water and absorber. In: Proceedings of “the 28th international conference on efficiency, cost, optimization, simulation and environmental impact of energy systems”, 30th June—3rd July 2015 Pau, France.

Swinbank WC. Long-wave radiation from clear skies. QJR Meteorol Soc. 1963;89:339–40.

Qiu Y, Li M-J, He Y-L, Tao W-Q. Thermal performance analysis of a parabolic trough solar collector using supercritical CO2 as heat transfer fluid under non-uniform solar flux. Appl Therm Eng. 2017;115:1255–65.

Behar O, Khellaf A, Mohammedi K. A novel parabolic trough solar collector model—validation with experimental data and comparison to engineering equation solver (EES). Energy Convers Manag. 2015;106:268–81.

Mwesigye A, Bello-Ochende T, Meyer JP. Heat transfer and thermodynamic performance of a parabolic trough receiver with centrally placed perforated plate inserts. Appl Energy. 2014;136:989–1003.

Mwesigye A, Bello-Ochende T, Meyer JP. Heat transfer and entropy generation in a parabolic trough receiver with wall-detached twisted tape inserts. Int J Therm Sci. 2016;99:238–57.

Acknowledgements

Dr. Evangelos Bellos would like to thank “Bodossaki Foundation” for its financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bellos, E., Tzivanidis, C. & Papadopoulos, A. Enhancing the performance of a linear Fresnel reflector using nanofluids and internal finned absorber. J Therm Anal Calorim 135, 237–255 (2019). https://doi.org/10.1007/s10973-018-6989-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-6989-1