Abstract

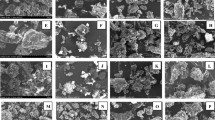

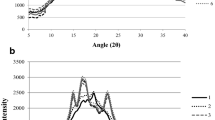

The effects of different doses of gamma radiation on the thermoanalytical, structural and pasting properties of black rice (Oryza sativa L.) flour were studied using thermogravimetry and derivative thermogravimetry (TG–DTG), differential scanning calorimetry, X-ray diffraction (XRD), field emission gun–scanning electron microscopy (FEG–SEM) and pasting properties (RVA) analysis. The thermogravimetric curves showed four mass losses. A small displacement was observed for the second loss, which occurred for the irradiated flours, compared to the control sample. The irradiated samples showed a slight decrease in the thermal parameters: initial temperature (T o), peak temperature (T p) and gelatinisation enthalpy (△H). All the black rice flours exhibited A-type crystallinity pattern, and the gamma radiation did not change the XRD patterns or the degree of crystallinity. The micro-images obtained using FEG–SEM showed a composite of organic and heterogeneous material; after gamma radiation, some changes occurred, such as cracks, pores and smaller fragments. The pasting properties decreased significantly with irradiation. The decrease in setback and breakdown viscosity after irradiation suggested an indication that it may be possible to improve the quality of food based on black rice flours. Gamma radiation can be a useful tool to modify rice flours in order to suit various functionalities and to help meet the growing demands of the food industry.

Similar content being viewed by others

References

Hu Z, Tang X, Liu J, Zhu Z, Shao Y. Effect of parboiling on phytochemical content, antioxidant activity and physicochemical properties of germinated red rice. Food Chem. 2017;214:285–92.

Ziegler V, Ferreira CD, Goebel JTS, El Halal SLM, Santetti GS, Gutkoski LC, et al. Changes in properties of starch isolated from whole rice grains with brown, black, and red pericarp after storage at different temperatures. Food Chem. 2017;216:194–200.

Hao J, Zhu H, Zhang Z, Yang S, Li H. Identification of anthocyanins in black rice (Oryza sativa L.) by UPLC/Q-TOF-MS and their in vitro and in vivo antioxidant activities. J Cereal Sci. 2015;64:92–9.

Zhang Y, Li P, Cheng L. Developmental changes of carbohydrates, organic acids, amino acids, and phenolic compounds in ‘Honeycrisp’ apple flesh. Food Chem. 2010;123(4):1013–8.

Liu T, Ma Y, Xue S, Shi J. Modifications of structure and physicochemical properties of maize starch by γ-irradiation treatments. LWT Food Sci Technol. 2012;46(1):156–63.

Polesi LF, Sarmento SBS, de Moraes J, Franco CML, Canniatti-Brazaca SG. Physicochemical and structural characteristics of rice starch modified by irradiation. Food Chem. 2016;191:59–66.

Siqueira GLA, Hornung PS, Silveira AC, Lazzarotto SRS, Cordoba LP, Schnitzler E, Lazzarotto M. Impact of treatment with HCL/alcoholic in the modification of corn starch. J Therm Anal Calorim. 2017;129(3):1705–13.

Gul K, Singh AK, Sonkawade RG. Physicochemical, thermal and pasting characteristics of gamma irradiated rice starches. Int J Biol Macromol. 2016;85:460–6.

Pereira C, Calhelha RC, Antonio AL, Queiroz MJRP, Barros L, Ferreira ICFR. Effects of gamma radiation on chemical and antioxidant properties, anti-hepatocellular carcinoma activity and hepatotoxicity of borututu. Innov Food Sci Emerg Technol. 2014;26:271–7.

Ito VC, Alberti A, Avila S, Spoto M, Nogueira A, Wosiacki G. Effects of gamma radiation on the phenolic compounds and in vitro antioxidant activity of apple pomace flour during storage using multivariate statistical techniques. Innov Food Sci Emerg Technol. 2016;33:251–9.

Bhat R, Karim AA. Impact of radiation processing on starch. Compr Rev Food Sci Food Saf. 2009;8(2):44–58.

Bao J, Ao Z, J-l Jane. Characterization of physical properties of flour and starch obtained from gamma-irradiated white rice. Starch-Stärke. 2005;57(10):480–7.

Ito VC, Ferreira Zielinski AA, Avila S, Spoto M, Nogueira A, Schnitzler E, Lacerda LG. Effects of gamma radiation on physicochemical, thermogravimetric, microstructural and microbiological properties during storage of apple pomace flour. LWT Food Sci Technol. 2017;78:105–13.

Hornung PS, Oliveira CS, Lazzarotto M, Lazzarotto SRS, Schnitzler E. Investigation of the photo-oxidation of cassava starch granules. J Therm Anal Calorim. 2016;123(3):2129–37.

Hornung PS, Cordoba LP, Lazzarotto SRS, Schnitzler E, Lazzarotto M, Ribani RH. Brazilian Dioscoreaceas starches. J Therm Anal Calorim. 2017;127(3):1869–77.

Bet CD, do Prado Cordoba L, Ribeiro LS, Schnitzler E. Common vetch (Vicia sativa) as a new starch source: its thermal, rheological and structural properties after acid hydrolysis. Food Biophys. 2016;11(3):275–82.

Kubiaki FT, Figueroa AM, Oliveira CS, Demiate IM, Schnitzler E, Lacerda LG. Effect of acid–alcoholic treatment on the thermal, structural and pasting characteristics of European chestnut (Castanea sativa, Mill) starch. J Therm Anal Calorim. 2016;. doi:10.1007/s10973-016-5832-9.

Liu X, Wang Y, Yu L, Tong Z, Chen L, Liu H, Li X. Thermal degradation and stability of starch under different processing conditions. Starch-Stärke. 2013;65(1–2):48–60.

Puncha-arnon S, Uttapap D. Rice starch vs. rice flour: differences in their properties when modified by heat–moisture treatment. Carbohydr Polym. 2013;91(1):85–91.

Zhang Q, Saleh ASM, Chen J, Sun P, Shen Q. Monitoring of thermal behavior and decomposition products of soybean oil. J Therm Anal Calorim. 2014;115(1):19–29.

Darfour B, Wilson DD, Ofosu DO, Ocloo FCK. Physical, proximate, functional and pasting properties of flour produced from gamma irradiated cowpea (Vigna unguiculata, L. Walp). Radiat Phys Chem. 2012;81(4):450–7.

Lopes BDM, Demiate IM, Ito VC, de Oliveira CS, da Silva Carvalho Filho MA, Schnitzler E, Lacerda LG. Effects of partial in vitro digestion on properties of European chestnut (Castanea sativa Mill) flour. Thermochim Acta. 2016;640:36–41.

Corradini E, Imam SH, Agnelli JAM, Mattoso LHC. Effect of coconut, sisal and jute fibers on the properties of starch/gluten/glycerol matrix. J Polym Environ. 2009;17(1):1–9.

Beninca C, Colman TAD, Lacerda LG, Filho MASC, Bannach G, Schnitzler E. The thermal, rheological and structural properties of cassava starch granules modified with hydrochloric acid at different temperatures. Thermochim Acta. 2013;552:65–9.

Cieśla K, Eliasson A-C. Influence of gamma radiation on potato starch gelatinization studied by differential scanning calorimetry. Radiat Phys Chem. 2002;64(2):137–48.

Rombo GO, Taylor JRN, Minnaar A. Irradiation of maize and bean flours: effects on starch physicochemical properties. J Sci Food Agric. 2004;84(4):350–6.

Kong X, Zhou X, Sui Z, Bao J. Effects of gamma irradiation on physicochemical properties of native and acetylated wheat starches. Int J Biol Macromol. 2016;91:1141–50.

Singh N, Kaur L, Sandhu KS, Kaur J, Nishinari K. Relationships between physicochemical, morphological, thermal, rheological properties of rice starches. Food Hydrocol. 2006;20(4):532–42.

Ocloo FCK, Owureku-Asare M, Agyei-Amponsah J, Agbemavor WSK, Egblewogbe MNYH, Apea-Bah FB, et al. Effect of gamma irradiation on physicochemical, functional and pasting properties of some locally-produced rice (Oryza spp) cultivars in Ghana. Radiat Phys Chem. 2017;130:196–201.

Chung HJ, Liu Q. Effect of gamma irradiation on molecular structure and physicochemical properties of corn starch. J Food Sci. 2009;74(5):C353–61.

Yu S, Ma Y, Menager L, Sun D-W. Physicochemical properties of starch and flour from different rice cultivars. Food Biotechnol. 2012;5(2):626–37.

Wu F, Chen H, Yang N, Wang J, Duan X, Jin Z, Xu X. Effect of germination time on physicochemical properties of brown rice flour and starch from different rice cultivars. J Cereal Sci. 2013;58(2):263–71.

Ashwar BA, Shah A, Gani A, Rather SA, Wani SM, Wani IA, Ahmed W, Masoodi FA, Gani A. Effect of gamma irradiation on the physicochemical properties of alkali-extracted rice starch. Radiat Phys Chem. 2014;99:37–44.

Kim H-Y, Park SS, Lim S-T. Preparation, characterization and utilization of starch nanoparticles. Colloids Surf B Biointerfaces. 2015;126:607–20.

Bhat NA, Wani IA, Hamdani AM, Gani A, Masoodi FA. Physicochemical properties of whole wheat flour as affected by gamma irradiation. LWT Food Sci Technol. 2016;71:175–83.

Acknowledgements

The authors are deeply grateful to the Coordination for the Improvement of Personnel in Higher Level (CAPES), Fundacão Araucária for funding and C-LABMU-UEPG for the infrastructure.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ito, V.C., Bet, C.D., Wojeicchowski, J.P. et al. Effects of gamma radiation on the thermoanalytical, structural and pasting properties of black rice (Oryza sativa L.) flour. J Therm Anal Calorim 133, 529–537 (2018). https://doi.org/10.1007/s10973-017-6766-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6766-6