Abstract

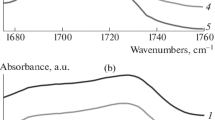

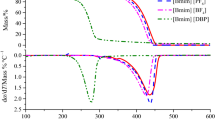

To improve the thermal performance and mechanical properties of nitramine propellant, varied proportions of GAP-ETPE/NC were applied as binders. The thermal behavior of propellants was investigated by using differential scanning calorimetry (DSC), the thermal stability of the propellants was studied by methyl violet experiment and vacuum stability test, and the mechanical properties were also examined. It was found that the DSC curve of GAP-ETPE shows a single exothermic peak at around 250 °C, and TG-DTG curves of GAP-ETPE exhibit two major steps of mass loss. GAP-ETPE has a good compatibility with nitrocellulose, and there is no interaction between GAP-ETPE and RDX in solid phrase. When increasing the proportion of GAP-ETPE content in the binder system, the decomposition peak of nitrocellulose disappears gradually and the peak temperature of main decomposition increases. Meanwhile, activation energy and frequency factor calculated by Kissinger and FWO methods using non-isothermal thermoanalytical data all increase slightly. And the thermal stability of propellant gets improved greatly when GAP-ETPE is introduced into the binder system. When the proportion of GAP-ETPE/NC is 1:1 and 1:2 in the binder system, the mechanical properties of nitramine propellant are relatively excellent.

Similar content being viewed by others

References

Winkler DA, Starks A. The non-Fickian diffusion of deterrents into a nitrocellulose-based propellant. J Appl Polym Sci. 1988;35:51–62.

Lindblom Torbjörn. Reactions in stabilizer and between stabilizer and nitrocellulose in propellants. Propellant Explos Pyrotech. 2002;27:197–208.

Chin A, Ellison D, Poehlein S. Investigation of the decomposition mechanism and thermal stability of nitrocellulose/nitroglycerine based propellants by electron spin resonance. Propellant Explos Pyrotech. 2007;32:117–26.

Sovizi MR, Hajimirsadeghi SS, Naderizadeh B. Effect of particle size on thermal decomposition of nitrocellulose. J Hazard Mater. 2009;168:1134–9.

Pourmortazavi SM, Hosseini SG, Rahimi-Nasrabadi M. Effect of nitrate content on thermal decomposition of nitrocellulose. J Hazard Mater. 2009;162:1141–4.

Wei W, Cui B, Jiang X. The catalytic effect of NiO on thermal decomposition of nitrocellulose. J Therm Anal Calorim. 2010;102:863–6.

Singh H, Khire V. Studies on low vulnerability gun propellants based on conventional binders and energetic plasticizers. Int J Energ Mater Chem Propuls. 2008;7:187–92.

Ampleman G. Development of a new generation of insensitive explosives and gun propellants. Int J Energ Mater Chem Propuls. 2010;9:107–32.

Pillai AGS, Sanghavi RR, Dayanandan CR. Studies on RDX particle size in LOVA gun propellant formulations. Propellant Explos Pyrotech. 2001;26:226–8.

Fathollahi M, Pourmortazavi SM, Hosseini SG. Particle size effects on thermal decomposition of energetic material. J Energ Mater. 2007;26:52–69.

Sanghavi RR, Kamale PJ, Shaikh MAR. HMX based enhanced energy LOVA gun propellant. J Hazard Mater. 2007;143:532–4.

Bayat Y, Hajimirsadeghi SS, Pourmortazavi SM. Statistical optimization of reaction parameters for the synthesis of 2,4,6,8,10,12-hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane. Org Process Res Dev. 2011;15:810–6.

Bayat Y, Pourmortazavi SM, Ahadi H. Taguchi robust design to optimize supercritical carbon dioxide anti-solvent process for preparation of 2,4,6,8,10,12-hexanitro-2,4,6,8,10,12-hexaazaisowurtzit ane nanoparticles. Chem Eng J. 2013;230:432–8.

Sanghavi RR, Asthana SN, Singh H. Thermoplastic elastomers (TPEs) as binders for futuristic propellants and explosives: a review. J Polym Mater. 2000;17:221–32.

Mulage KS, Patkar RN, Deuskar VD. Studies on a novel thermoplastic polyurethane as a binder for extruded composite propellants. J Energ Mater. 2007;25:233–45.

Xiao Z, He W, Ying S. Current trends in energetic thermoplastic elastomers as binders in high energy insensitive propellants in China. Sci Technol Energ Mater. 2014;75:37–43.

Yeganeh H, Shamekhi MA. Poly(urethane-imide-imide), a new generation of thermoplastic polyurethane elastomers with enhanced thermal stability. Polymer. 2004;45:359–65.

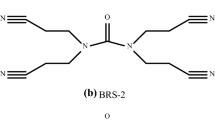

Zhang Z, Gang W, Zhen W. Synthesis and characterization of novel energetic thermoplastic elastomers based on glycidyl azide polymer (GAP) with bonding functions. Polym Bull. 2015;72:1835–47.

Eceiza A, Martin MD, Caba KDL. Thermoplastic polyurethane elastomers based on polycarbonate diols with different soft segment molecular weight and chemical structure: mechanical and thermal properties. Polym Eng Sci. 2008;48:297–306.

Kultys A, Rogulska M, Halina G. The effect of soft-segment structure on the properties of novel thermoplastic polyurethane elastomers based on an unconventional chain extender. Polym Int. 2011;60:652–9.

Fan XP, Tan HM, Lei Z. Influence of thermoplastic polyurethane on mechanical properties of modified double base propellants. Tuijin Jishu/J Propuls Technol. 2008;29:124–8.

Shamsipur M, Pourmortazavi SM, Hajimirsadeghi SS. Effect of functional group on thermal stability of cellulose derivative energetic polymers. Fuel. 2012;95:394–9.

Diaz E, Brousseau P, Ampleman G. Heats of combustion and formation of new energetic thermoplastic elastomers based on GAPPolyNIMMO and PolyGLYN. Propellant Explos Pyrotech. 2003;28:101–6.

Li Ning, Xiao LQ, Zhou WL. Energy characteristics analysis of GAP-ETPE propellant formulations. Chin J Expl Propellant. 2010;33:74–7.

Arun K, Sreekantha R. Review on energetic thermoplastic elastomers (ETPEs) for military science. Propellant Explos Pyrotech. 2013;38:14–28.

Pisharath S, Ang HG. Synthesis and thermal decomposition of GAP–Poly(BAMO) copolymer. Polym Degrad Stab. 2007;92:1365–77.

You JS, Kweon JO, Kang SC. A kinetic study of thermal decomposition of glycidyl azide polymer (GAP)-based energetic thermoplastic polyurethanes. Macromol Res. 2010;18:1226–32.

Wang Z, Zhang T, Zhang Z. Effect of hard-segment content on rheological properties of glycidyl azide polyol-based energetic thermoplastic polyurethane elastomers. Polym Bull. 2016;73:1–10.

Zuo HL, Xiao LQ, Jian XX. Preparation and characterization of polymer blends of NC and GAP-TPE. J Solid Rock Technol. 2011;34:488–91.

Hu YW, Zheng QL, Zhou WL. Preparation and performance of GAP-ETPE/NC polymer blends. Chin J Energ Mater. 2016;24:331–5.

Pei JF, Zhao FQ, Lu HL. Compatibility study of BAMO–GAP copolymer with some energetic materials. J Therm Anal Calorim. 2016;124:1301–7.

Niehaus M. Compounding of glycidyl azide polymer with nitrocellulose and its influence on the properties of propellants. Propellant Explos Pyrotech. 2000;25:236–40.

You JS, Kang SC, Kweon SK, et al. Thermal decomposition kinetics of GAP ETPE/RDX-based solid propellant. Thermochim Acta. 2012;537:51–6.

He XJ, Xu X, Du LP. Effect of thermoplastic elastomer on mechanical properties and combustion performance of nitroamine propellant. Chin J Energ Mater. 2011;19:65–8.

Singh G, Felix SP, Soni P. Studies on energetic compounds part 28: thermolysis of HMX and its plastic bonded explosives containing Estane. Thermochim Acta. 2003;399:153–65.

Zhang K, Yi L, Hui Q. Thermal decomposition and combustion performance of RDX/POLY(BAMO-AMMO) based gun propellant. Chin J Explos Propellant. 2014;31:82–5.

Sinha YK, Sridhar BTN, Santhosh M. Thermal decomposition study of HTPB solid fuel in the presence of activated charcoal and paraffin. J Therm Anal Calorim. 2015;119:557–65.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29:1702–6.

Abusaidi H, Ghaieni HR, Pourmortazavi SM. Effect of nitro content on thermal stability and decomposition kinetics of nitro-HTPB. J Therm Anal Calorim. 2016;124:1–7.

Rocco JAFF, Lima JES, Frutuoso AG. Thermal degradation of a composite solid propellant examined by DSC-Kinetic study. J Therm Anal Calorim. 2004;75:551–7.

Tang W, Chen D. An integral method to determine variation in activation energy with extent of conversion. Thermochim Acta. 2005;433:72–6.

GJB 772A-97 501.2. Standard test methods for stability and compatibility. Military standards in China; 1997. p. 156–62.

Jai Prakash Agrawal. Some new high energy materials and their formulations for specialized applications. Propellant Explos Pyrotech. 2005;30:316–28.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, M., Ma, Z., He, L. et al. Effect of varied proportion of GAP-ETPE/NC as binder on thermal decomposition behaviors, stability and mechanical properties of nitramine propellants. J Therm Anal Calorim 130, 909–918 (2017). https://doi.org/10.1007/s10973-017-6351-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6351-z