Abstract

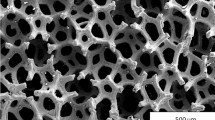

Decanoic acid/expanded graphite composite phase change materials (DA/EG-PCMs) with high stability and excellent thermal conductivity were fabricated by blending expanded graphite (EG) and decanoic acid (DA). The structure, thermo-physical properties, and the formation mechanism of DA/EG-PCMs were investigated. The obtained results demonstrate that EG exhibits a network-like porous structure, which is superimposed of 10–50 μm thick graphite sheet. Therefore, DA can be effectively encapsulated through the binding between micropores and the surface adsorption of EG resulting in a relatively smaller DA/EG-PCMs particle with better dispersibility. In addition, adding EG into DA also increased both the thermal stability and the thermal conductivity while decreasing the charging and discharging time, which resulted in improved thermal efficiencies. Although adding EG can negatively influence the phase change behavior of DA, the temperature and enthalpy of phase change were still as high as 34.9 °C and 153.1 J g−1, respectively. Based on a combination of experimental results and a comprehensive analysis of the phase transformation kinetics, it is concluded that DA/EG-PCMs with 10 mass% EG with improved thermal properties can meet the requirements for efficient temperature control in low-to-medium environments.

Similar content being viewed by others

References

Cheralathan M, Velraj R, Renganarayanan S. Heat transfer and parametric studies of an encapsulated phase change material based cool thermal energy storage system. J Zhejiang Univ Sci A. 2006;7(11):1886–95.

Ho CJ, Gao JY. Preparation and thermophysical properties of nanoparticle-in-paraffin emulsion as phase change material. Int Commun Heat Mass Transf. 2009;36(5):467–70.

Ince S, Seki Y, Ezan MA, et al. Thermal properties of myristic acid/graphite nanoplates composite phase change materials. Renew Energy. 2015;75:243–8.

Lin Y, Chen HL. Thermal analysis and adiabatic calorimetry for early-age concrete members. J Therm Anal Calorim. 2015;122(2):937–45.

Varol Y, Koca A, Oztop HF, et al. Forecasting of thermal energy storage performance of phase change material in a solar collector using soft computing techniques. Expert Syst Appl. 2010;37(4):2724–32.

Qiu X, Lu L, Zhang Z, et al. Preparation, thermal property, and thermal stability of microencapsulated n-octadecane with poly (stearyl methacrylate) as shell. J Therm Anal Calorim. 2014;118(3):1441–9.

Zheng Y, Barton JL, Tuzla K, et al. Experimental and computational study of thermal energy storage with encapsulated NaNO 3 for high temperature applications. Sol Energy. 2015;115:180–94.

Zhang GH, Zhao CY. Thermal property investigation of aqueous suspensions of microencapsulated phase change material and carbon nanotubes as a novel heat transfer fluid. Renew Energy. 2013;60:433–8.

Zhao L, Wan T, Yang X, et al. Effects of kaolinite addition on the melting characteristics of the reaction between phosphogypsum and CaS. J Therm Anal Calorim. 2015;119(3):2119–26.

Silva LFO, Hower JC, Izquierdo M, et al. Complex nanominerals and ultrafine particles assemblages in phosphogypsum of the fertilizer industry and implications on human exposure. Sci Total Environ. 2010;408(21):5117–22.

Warzoha RJ, Fleischer AS. Improved heat recovery from paraffin-based phase change materials due to the presence of percolating graphene networks. Int J Heat Mass Transf. 2014;79:314–23.

Wu SY, Tong X, Nie CD, et al. The effects of various carbon nanofillers on the thermal properties of paraffin for energy storage applications. J Therm Anal Calorim. 2016;124(1):181–8.

Trigui A, Karkri M, Krupa I. Thermal conductivity and latent heat thermal energy storage properties of LDPE/wax as a shape-stabilized composite phase change material. Energy Convers Manag. 2014;77:586–96.

Wang L, Meng D. Fatty acid eutectic/polymethyl methacrylate composite as form-stable phase change material for thermal energy storage. Appl Energy. 2010;87(8):2660–5.

Li H, Ji X, Leng C, et al. Thermal performance of expanded graphite/Na2S2O3·5H2O phase change energy storage composite. Acta Mater Compos Sinic. 2016;33(12):2941–51.

Sarı A, Sarı H, Önal A. Thermal properties and thermal reliability of eutectic mixtures of some fatty acids as latent heat storage materials. Energy Convers Manag. 2004;45(3):365–76.

Sarı A. Eutectic mixtures of some fatty acids for latent heat storage: thermal properties and thermal reliability with respect to thermal cycling. Energy Convers Manag. 2006;47(9):1207–21.

Babaei H, Keblinski P, Khodadadi JM. Thermal conductivity enhancement of paraffins by increasing the alignment of molecules through adding CNT/graphene. Int J Heat Mass Transf. 2013;58(1):209–16.

Zhang P, Hu Y, Song L, et al. Effect of expanded graphite on properties of high-density polyethylene/paraffin composite with intumescent flame retardant as a shape-stabilized phase change material. Sol Energy Mater Sol Cells. 2010;94(2):360–5.

Tang F, Cao L, Fang G. Preparation and thermal properties of stearic acid/titanium dioxide composites as shape-stabilized phase change materials for building thermal energy storage. Energy Build. 2014;80:352–7.

Zhong LM, Yang M, Luan L. Preparation and properties of paraffin/SiO2 composite phase change materials. Chin J Eng. 2015;37(7):936–41.

Zhang XR, Zhu DS, Gao JW. Study on thermal properties of graphite/paraffin composites as phase change heat storage materia. Chin J Mater Res. 2010;24(3):332–6.

Li JF, Lu W, Zeng YB, et al. Simultaneous enhancement of latent heat and thermal conductivity of docosane-based phase change material in the presence of spongy graphene. Sol Energy Mater Sol Cells. 2014;128:48–51.

Yang H, Mao J, Feng J. Investigation on preparation and performance of paraffin/silicon dioxide composite phase change materials. Mater Rev. 2010;24(15):278–80.

Yang JG, Wu CP. Morphology and X-ray photoelectron spectroscopy of expanded graphite. J Mater Sci Eng. 2007;25(2):294–7.

Sarı A, Karaipekli A. Thermal conductivity and latent heat thermal energy storage characteristics of paraffin/expanded graphite composite as phase change material. Appl Therm Eng. 2007;27(8):1271–7.

Huang X, Cui YD, Yin GQ, Zhang BN. Preparation and phase transformation kinetic of organic modified montmorillonite based composite phase change material. Mater Rev. 2015;29(8):63–6.

Zhang WP, Tong F, Xing YS. Experimental study and prediction model of thermal conductivity of concrete. J Build Mater. 2015;18(2):183–9.

Zhu FR, Zhang L, Zeng JL, et al. Preparation and thermal properties of palmitic acid/polyaniline/copper nanowires form-stable phase change materials. J Therm Anal Calorim. 2014;115(2):1133–41.

Yu H, Gao J, Chen Y, et al. Preparation and properties of stearic acid/expanded graphite composite phase change material for low-temperature solar thermal application. J Therm Anal Calorim. 2016;124(1):87–92.

Zhang H, Huang XJ, Liu XY. Optimization for preparation of phase change and humidity control composite materials of hexadecanol-palmitic acid-lauric acid/SiO2. Chin J Mater Res. 2015;29(9):671–7.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Li, Y., Yan, H., Wang, Q. et al. Structure and thermal properties of decanoic acid/expanded graphite composite phase change materials. J Therm Anal Calorim 128, 1313–1326 (2017). https://doi.org/10.1007/s10973-016-6068-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-6068-4