Abstract

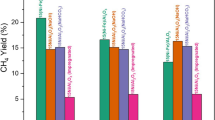

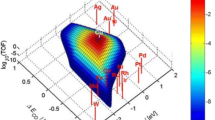

The relationship between the properties with the composition of nickel–aluminium mixed oxides was investigated in this work. Ni–Al materials with Ni/Al molar ratios between 0.5 and 9 were synthesised via co-precipitation. The samples were characterised using the following techniques: surface area measurements (S BET), thermogravimetry, X-ray diffraction and temperature-programmed reduction, desorption and oxidation (H2-TPR, NH3-TPD and TPO/DTA). Samples with Ni/Al ratio = 0.5 primarily formed the Al2O3 phase, whereas Ni/Al ratio = 9 mainly led to the bulk NiO phase. However, Ni/Al ratios between 1 and 3 favoured the formation of the mixed oxide phase with increased thermal stability and specific surface area and decreased crystallite sizes. The lower Ni/Al ratios led to the production of ethylene, which is likely related to the higher number of sites with stronger acidity. The samples with Ni/Al ratios of 2 and 3 promoted selectivity towards synthesis gas. For higher Ni/Al ratios, low thermal stability leading to sintering and deactivation due to coke formation was observed.

Similar content being viewed by others

References

Ma R, Castro-Dominguez B, Mardilovich I, Dixon AG, Ma YH. Experimental and simulation studies of the production of renewable hydrogen through ethanol steam reforming in a large-scale catalytic membrane reactor. Chem Eng J. 2016;303:302–13.

Divins NJ, Llorca J. In situ photoelectron spectroscopy study of ethanol steam reforming over RhPd nanoparticles and RhPd/CeO2. Appl Catal A Gen. 2016;518:60–6.

Gallego J, Sierra G, Mondragon F, Barrault J, Batiot-Dupeyrat C. Synthesis of MWCNTs and hydrogen from ethanol catalytic decomposition over a Ni/La2O3 catalyst produced by the reduction of LaNiO3. Appl Catal A Gen. 2011;397:73–81.

Fajardo H, Longo E, Mezalira D, Nuernberg G, Almerindo G, Collasiol A, Probst LD, Garcia IS, Carreño NV. Influence of support on catalytic behavior of nickel catalysts in the steam reforming of ethanol for hydrogen production. Environ Chem Lett. 2010;8(1):79–85.

Wang G, Wang H, Li W, Ren Z, Bai J, Bai J. Efficient production of hydrogen and multi-walled carbon nanotubes from ethanol over Fe/Al2O3 catalysts. Fuel Process Technol. 2011;92(3):531–40.

Mezalira DZ, Probst LD, Pronier S, Batonneau Y, Batiot-Dupeyrat C. Decomposition of ethanol over Ni/Al2O3 catalysts to produce hydrogen and carbon nanostructured materials. J Mol Catal A Chem. 2011;340(1–2):15–23.

Liu Q, Ouyang Y, Zhang L, Xu Y, Fang Y. Effects of argon flow rate and reaction temperature on synthesizing single-walled carbon nanotubes from ethanol. Phys E. 2009;41(7):1204–9.

Tian R, Wang X, Li M, Hu H, Chen R, Liu F, Zheng H, Wan L. An efficient route to functionalize singe-walled carbon nanotubes using alcohols. Appl Surf Sci. 2008;255(5,2):3294–9.

Jones G, Jakobsen JG, Shim SS, Kleis J, Andersson MP, Rossmeisl J, Abild-Pedersen F, Bligaard T, Helveg S, Hinnemann B, et al. First principles calculations and experimental insight into methane steam reforming over transition metal catalysts. J Catal. 2008;259(1):147–60.

Rostrup-Nielsen JR, Hansen JHB. CO2-reforming of methane over transition metals. J Catal. 1993;144(1):38–49.

Rostrup-Nielsen JR. Production of synthesis gas. Catal Today. 1993;18(4):305–24.

Wang G, Wang H, Tang Z, Li W, Bai J. Simultaneous production of hydrogen and multi-walled carbon nanotubes by ethanol decomposition over Ni/Al2O3 catalysts. Appl Catal B Environ. 2009;88(1–2):142–51.

Barthos R, Széchenyi A, Koós Á, Solymosi F. The decomposition of ethanol over Mo2C/carbon catalysts. Appl Catal A Gen. 2007;327(1):95–105.

Gao F, Zhang L, Yang Y, Huang S. Quality of horizontally aligned single-walled carbon nanotubes: is methane as carbon source better than ethanol? Appl Surf Sci. 2010;256(11):3357–60.

Li W, Wang H, Ren Z, Wang G, Bai J. Co-production of hydrogen and multi-wall carbon nanotubes from ethanol decomposition over Fe/Al2O3 catalysts. Appl Catal B Environ. 2008;84(3–4):433–9.

Igarashi H, Murakami H, Murakami Y, Maruyama S, Nakashima N. Purification and characterization of zeolite-supported single-walled carbon nanotubes catalytically synthesized from ethanol. Cehm Phys Lett. 2004;392(4–6):529–32.

Wang G, Wang H, Li W, Bai J. Preparation of hydrogen and carbon nanotubes over cobalt-containing catalysts via catalytic decomposition of ethanol. RSC Adv. 2011;1(8):1585–92.

Holgado MJ, Rives V, San Roman MS. Characterization of Ni–Mg–Al mixed oxides and their catalytic activity in oxidative dehydrogenation of n-butane and propene. Appl Catal A Gen. 2001;214(2):219–28.

Vaccari A. Preparation and catalytic properties of cationic and anionic clays. Catal Today. 1998;41(1–3):53–71.

Trifiró F, Vaccari A. Hydrotalcite-like anionic clays (layer double hydroxides). Comprehensive supramolecular chemistry, vol. 7. Oxford: Pergamon; 1996. p. 251.

Hermes NA, Lansarin MA, Perez-Lopez OW. Catalytic decomposition of methane over M–Co–Al catalysts (M = Mg, Ni, Zn, Cu). Catal Lett. 2011;141(7):1018–25.

Bhattacharyya A, Chang VW, Schumacher DJ. CO2 reforming of methane to syngas: I: evaluation of hydrotalcite clay-derived catalysts. Appl Clay Sci. 1998;13(5–6):317–28.

Mas V, Dieuzeide ML, Jobbagy M, Baronetti G, Amadeo N, Laborde M. Ni(II)–Al(III) layered double hydroxide as catalyst precursor for ethanol steam reforming: activation treatments and kinetic studies. Catal Today. 2008;133:319–23.

Muroyama H, Nakase R, Matsui T, Eguchi K. Ethanol steam reforming over Ni-based spinel oxide. Int J Hydrogen Energy. 2010;35(4):1575–81.

Resini C, Montanari T, Barattini L, Ramis G, Busca G, Presto S, Riani P, Marazza R, Sisani M, Marmottini F, et al. Hydrogen production by ethanol steam reforming over Ni catalysts derived from hydrotalcite-like precursors: catalyst characterization, catalytic activity and reaction path. Appl Catal A Gen. 2009;355(1–2):83–93.

Busca G, Costantino U, Montanari T, Ramis G, Resini C, Sisani M. Nickel versus cobalt catalysts for hydrogen production by ethanol steam reforming: Ni–Co–Zn–Al catalysts from hydrotalcite-like precursors. Int J Hydrogen Energy. 2010;35(11):5356–66.

Liu Z, Xu W, Yao S, Johnson-Peck AC, Zhao F, Michorczyk P, Kubacka A, Stach EA, Fernández-García M, Senanayake SD, Rodriguez JA. Superior performance of Ni–W–Ce mixed-metal oxide catalysts for ethanol steam reforming: synergistic effects of W- and Ni-dopants. J Catal. 2015;321:90–9.

Rached JA, El Hayek C, Dahdah E, Gennequin C, Aouad S, Tidahy HL, Estephane J, Nsouli B, Aboukaïs A, Abi-Aad E. Ni based catalysts promoted with cerium used in the steam reforming of toluene for hydrogen production. Int J Hydrogen Energy. 2016. doi:10.1016/j.ijhydene.2016.10.053.

Nwafal M, Gennequin C, Labaki M, Nsouli B, Aboukaïs A, Abi-Aad E. Hydrogen production by methane steam reforming over Ru supported on Ni–Mg–Al mixed oxides prepared via hydrotalcite route. Int J Hydrogen Energy. 2015;40(2):1269–77.

Jiao Y, Du Y, Zhang J, Li C, Xue Y, Lu J, Wang J, Chen Y. Steam reforming of n-decane for H2 production over Ni modified La-Al2O3 catalysts: effects of the active component Ni content. J Anal Appl Pyrol. 2015;116:58–67.

Gutiérrez-Ortiz JI, de Rivas B, López-Fonseca R, González-Velasco JR. Characterization of the catalytic properties of ceria-zirconia mixed oxides by temperature-programmed techniques. J Therm Anal Calorim. 2005;80(1):225–8.

Smoláková L, Frolich K, Troppová I, Kutálek P, Kroft E, Čapek L. Determination of basic sites in Mg–Al mixed oxides by combination of TPD-CO2 and CO2 adsorption calorimetry: when the same basic sites are reported from both techniques? J Therm Anal Calorim. 2016. doi:10.1007/s10973-016-5851-6.

Casenave S, Martinez H, Guimon C, Auroux A, Hulea V, Dumitriu E. Acid-Base properties of MgCuAl mixed oxides. J Therm Anal Calorim. 2003;72(1):191–8.

Zygmuntowicz J, Wiecinska P, Miazga A, Konopka K. Characterization of composites containing NiAl2O4 spinel phase from Al2O3/NiO and Al2O3/Ni systems. J Therm Anal Calorim. 2016;125:1079–86.

Kovanda F, Rojka T, Bezdicka P, Jiratova K, Obalova L, Pacultova K, Bastl Z, Grygar T. Effect of hydrothermal treatment on properties of Ni–Al layered double hydroxides and related mixed oxides. J Solid State Chem. 2009;182(1):27–36.

Vaccari A. Clays and catalysis: a promising future. Appl Clay Sci. 1999;14(4):161–98.

Di Cosimo JI, Díez VK, Xu M, Iglesia E, Apesteguía CR. Structure and surface and catalytic properties of Mg–Al basic oxides. J Catal. 1998;178(2):499–510.

Frost RL, Musumeci AW, Bostrom T, Adebajo MO, Weier ML, Martens W. Thermal decomposition of hydrotalcite with chromate, molybdate or sulphate in the interlayer. Thermochim Acta. 2005;429(2):179–87.

Crepaldi EL, Pavan PC, Valim JB. Comparative study of the coprecipitation methods for the preparation of layered double hydroxides. J Braz Chem Soc. 2000;11:64–70.

Palmer SJ, Spratt HJ, Frost RL. Thermal decomposition of hydrotalcites with variable cationic ratios. J Therm Anal Calorim. 2009;95(1):123–9.

de Souza G, Ávila VC, Marcílio NR, Perez-Lopez OW. Synthesis gas production by steam reforming of ethanol over M–Ni–Al hydrotalcite-type catalysts; M = Mg, Zn, Mo, Co. Proc Eng. 2012;42:1805–15.

Zhang LH, Xiang X, Zhang L, Li F, Zhu J, Evans DG, Duan X. Influence of iron substitution on formation and structure of Cu-based mixed oxides derived from layered double hydroxides. J Phys Chem Solids. 2008;69(5–6):1098–101.

Montoya JA, Romero-Pascual E, Gimon C, Del Angel P, Monzon A. Methane reforming with CO2 over Ni/ZrO2–CeO2 catalysts prepared by sol–gel. Catal Today. 2000;63(1):71–85.

Guo JJ, Lou H, Zhao H, Chai DF, Zheng XM. Dry reforming of methane over nickel catalysts supported on magnesium aluminate spinels. Appl Catal A Gen. 2004;273(1–2):75–82.

Cavani F, Trifiro F, Vaccari A. Hydrotalcite-type anionic clays: preparation, properties and applications. Catal Today. 1991;11(2):173–301.

Perez-Lopez OW, Senger A, Marcilio NR, Lansarin MA. Effect of composition and thermal pretreatment on properties of Ni–Mg–Al catalysts for CO2 reforming of methane. Appl Catal A Gen. 2006;303(2):234–44.

Aasberg-Petersen K, Dybkjær I, Ovesen CV, Schjødt NC, Sehested J, Thomsen SG. Natural gas to synthesis gas—catalysts and catalytic processes. J Nat Gas Sci Eng. 2011;3(2):423–59.

Ewbank JL, Kovarik L, Kenvin CC, Sievers C. Effect of preparation methods on the performance of Co/Al2O3 catalysts for dry reforming of methane. Green Chem. 2014;16(2):885–96.

de Sousa FF, de Sousa HSA, Oliveira AC, Junior MCC, Ayala AP, Barros EB, Viana BC, Filho JM, Oliveira AC. Nanostructured Ni-containing spinel oxides for the dry reforming of methane: effect of the presence of cobalt and nickel on the deactivation behaviour of catalysts. Int J Hydrogen Energy. 2012;37(4):3201–12.

Escobar C, Perez-Lopez O. Hydrogen production by methane decomposition over Cu–Co–Al mixed oxides activated under reaction conditions. Catal Lett. 2014;144:796–804.

Xu Z, Li Y, Zhang J, Chang L, Zhou R, Duan Z. Bound-state Ni species—a superior form in Ni-based catalyst for CH4/CO2 reforming. Appl Catal A Gen. 2001;210(1–2):45–53.

Li G, Hu L, Hill JM. Comparison of reducibility and stability of alumina-supported Ni catalysts prepared by impregnation and co-precipitation. Appl Catal A Gen. 2006;301(1):16–24.

Boukha Z, Jiménez-González C, de Rivas B, González-Velasco JR, Gutiérrez-Ortiz JI, López-Fonseca R. Synthesis, characterisation and performance evaluation of spinel-derived Ni/Al2O3 catalysts for various methane reforming reactions. Appl Catal B Environ. 2014;158–159:190–201.

Han YS, Li JB, Ning XS, Chi B. Effect of preparation temperature on the lattice parameter of nickel aluminate spinel. J Am Chem Soc. 2004;87(7):1347–9.

Clause O, Rebours B, Merlen E, Trifiró F, Vaccari A. Preparation and characterization of nickel–aluminum mixed oxides obtained by thermal decomposition of hydrotalcite-type precursors. J Catal. 1992;133(1):231–46.

Cesteros Y, Salagre P, Medina F, Sueiras JE. Preparation and characterization of several high-area NiAl2O4 spinels. Study of their reducibility. Chem Mater. 2000;12(2):331–5.

Dancini-Pontes I, Fernandes-Machado NRC, Souza M, Pontes RM. Insights into ethanol decomposition over Pt: a DFT energy decomposition analysis for the reaction mechanism leading to C2H6 and CH4. Appl Catal A Gen. 2015;491:86–93.

Xing S-K, Wang G-C. Reaction mechanism of ethanol decomposition on Mo2C(1 0 0) investigated by the first principles study. J Mol Catal A Chem. 2013;377:180–9.

Choi IM, Liu P. Understanding of ethanol decomposition on Rh(1 1 1) from density functional theory and kinetic Monte Carlo simulations. Catal Today. 2011;165(1):64–70.

Acknowledgements

The authors wish to thank the financial support and scholarships granted by the “Conselho Nacional de Desenvolvimento Científico e Tecnológico—CNPq” and by the “Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—CAPES”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Souza, G., Marcilio, N.R. & Perez-Lopez, O.W. Influence of the Ni/Al ratio on Ni–Al mixed oxides and their catalytic properties for ethanol decomposition. J Therm Anal Calorim 128, 735–744 (2017). https://doi.org/10.1007/s10973-016-6034-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-6034-1