Abstract

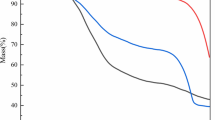

Polylactide (PLA) composites with three types of fillers, calcium carbonate, barium sulfate, and mica, have been prepared. Methods of preparation were melt mixing in a Brabender plasticorder at 190 °C and solution mixing in chloroform. The concentration of added fillers was: 0.1, 1, and 5 mass% (only by melt mixing). Thermal properties of prepared composites were investigated by differential scanning calorimetry (DSC) and thermogravimetric analysis. The dispersity of filler in matrix was examined by scanning electron microscopy. There was no agglomeration in any composites. Results of DSC analysis reveal the influence of preparation method on thermal transitions. By the melt mixing method, the introduced filler hindered crystallization but caused mostly just a slight increase in T g relative to pure PLA (57.4 °C). By solution-mixing method, the absence of crystallization is noticed in all samples. Concurrently composites displayed T g higher for ca. 5–6 °C relative to pure PLA (53.3 °C), with the exception of composite with smallest content of calcium carbonate nanofiller. Thermal stability is improved in all composites, regardless of the filler used and preparation method. It is especially pronounced regarding decomposition temperature (5 mass% loss) where the increase ranges from 11 up to 55 °C in case of melt mixing and 17–35 °C for solution mixing.

Similar content being viewed by others

References

Müllhaupt R. Greeen polymer chemistry and bio-based plastics: dreams and reality. Macromol Chem Phys. 2013;214:159–74.

Jing L, Zhang J. Biodegradable and biobased polymers. In: Kutz M, editor. Applied plastics engineering handbook: processing and materials. Oxford: William Andrew is and Imprint of Elsevier; 2011. p. 145–58.

Hakkarainene M, Finne-Wistrand A. Polylactide. In: Thomas S, Visakh PM, editors. Handbook of engineering and speciality thermoplastics: polyethers and polyesters, vol. 3. New Jersey: Wiley; 2011. p. 349–76.

http://www.environmentalleader.com/2010/03/08/bio-plastic-water-bottles-trickle-into-marketplace/. Accessed 20 Oct 2015.

Xu Y, Loi J, Delgado P, Topolkaraev V, McEneany RJ, Christopher W. Macosko CW, Hillmyer MA. Reactive compatibilization of polylactide/polypropylene blends. Ind Eng Chem Res. 2015;54:6108–14.

Jiang L, Wolcott MP, Zhang J. Study of biodegradable polylactide/poly(butylene adipate-co-terephthalate) blends. Biomacromolecules. 2006;7:199–207.

Lim L-T, Auras R, Rubino M. Processing technologies for poly(lactic acid). Prog Polym Sci. 2008;33:820–52.

Schmack G, Tändler B, Optiz G, Vogel R, Komber H, Häußler L, Voigt D, Weinmann S, Heinemann M, Fritz H-G. High-speed melt spinning of various grades of polylactides. J App Polym Sci. 2004;91:800–6.

Monnier X, Delpouve N, Basson N, Guinault A, Domenek S, Saiter A, Mallon PE, Dargent E. Molecular dynamics in electrospun amorphous plasticized polylactide fibers. Polymer. 2015;73:68–78.

Gruber PR, Kolstad JJ, Ryan CM, Hall ES, Conn RSE (1996) Melt-stable amorphous lactide polymer film and process for manufacturing thereof. US Patent 5,484,88.

Ljungberg N, Andersson T, Wesslen B. Film extrusion and film weldability of poly(lactic acid) plasticized with triacetine and tributyl citrate. J Appl Polym Sci. 2003;88:3239–47.

Bosiers L, Engelmann S. Thermoformed packaging made of PLA. Kunstst Plast Eur. 2003;12:21–4.

Silvino AC, Corrêa PS, Dias ML. Preparation of PLLA/PDLA stereocomplexes using a novel initiator based on Mg(II) and Ti(IV) alkoxides. J Appl Polym Sci. 2014;131:9299–306.

He Y, Xu Y, Wei J, Fan Z, Li S. Unique crystallization behavior of poly(l-lactide)/poly(d-lactide) stereocomplex depending on initial melt states. Polymer. 2008;49:5670–5.

Ahmed J, Varsheney SK, Auras R. Rheological and thermal properties of polylactide/silicate nanocomposites films. J Food Sci. 2010;75:N17–24.

Ahmed J, Varsheney SK, Auras R, Hwang SW. Thermal and rheological properties of l-polylactide/polyethylene glycol/silicate nanocomposites films. J Food Sci. 2010;75:N97–108.

http://www.intechopen.com/books/integrated-waste-management-volume-i/environmental-friendly-biodegradable-polymers-and-composites. Accessed 20 Oct 2015.

Notta-Cuvier D, Odent J, Delille R, Murariu M, Lauro F, Raquez JM, Bennani B, Dubois P. Tailoring polylactide (PLA) properties for automotive applications: effect of addition of designed additives on main mechanical properties. Polym Test. 2014;36:1–9.

Stoclet G, Seguela R, Lefebvre J-M. Morphology, thermal behavior and mechanical properties of binary blends of compatible biosourced polymers: polylactide/polyamide11. Polymer. 2011;52:1417–25.

Stoyanova N, Mincheva R, Paneva D, Manolova N, Dubois P, Rashkov I. Electrospun non-woven mats from stereocomplex between high molar mass poly(l-lactide) and poly(d-lactide)-block-poly(butylene succinate) copoly(ester urethane)s. Eur Polym J. 2012;48:1965–75.

Chen B-K, Shen C-H, Chen S-C, Chen AF. Ductile PLA modified with methacryloyloxyalkyl isocyanate improves mechanical properties. Polymer. 2010;51:4667–72.

Cele HM, Ojijo V, Chen H, Kumar S, Land K, Joubert T, de Villiers MFR, Ray SS. Effect of nanoclay on optical properties of PLA/clay composite films. Polym Test. 2014;36:24–31.

Reinhardt M, Kaufmann J, Kausch M, Kroll L. PLA-viscose-composites with continuous fibre reinforcement for structural applications. Procedia Mater Sci. 2013;2:137–43.

Reddy B. Advances in diverse industrial applications of nanocomposites. InTech;2011.

https://www.researchgate.net/publication/297735859_Nanostructured_biocomposites_from_aliphatic_polyesters_and_bacterial_cellulose. Accessed 21 March 2016.

Mo Y, Guo R, Liu J, Lan Y, Zhang Y, Xue W, Zhang Y. Preparation and properties of PLGA nanofiber membranes reinforced with cellulose nanocrystals. Colloids Surf B Biointerfaces. 2015;132:177–84.

Liu Y, Li Y, Chen H, Yang G, Zheng X, Zhou S. Water-induced shape-memory poly(d, l-lactide)/microcrystalline cellulose composites. Carbohyd Polym. 2014;104:101–8.

Kim H-Y, Park SS, Lim S-T. Preparation, characterization and utilization of starch nanoparticles. Colloids Surf B Biointerfaces. 2015;126:607–20.

Wokadala OC, Emmambux NM, Ray SS. Inducing PLA/starch compatibility through butyl-etherification of waxy and high amylose starch. Carbohyd Polym. 2014;112:216–24.

Staufenberg G, Graupner N, Müssig J. Impact and hardness optimisation of composite materials inspired by the babassu nut (Orbignya speciosa). Bioinspir Biomim. 2015;10: Art. No. 056006. doi:10.1088/1748-3190/10/5/056006.

Wu T-Y, Yang M-C, Hsu Y-C. Improvement of cytocompatibility of polylactide by filling with marine algae powder. Mater Sci Eng, C. 2015;50:309–16.

Yang JH, Lee JY, Chin I-J. Reinforcing effects of poly(d-lactide)-g-multiwall carbon nanotubes on polylactide nanocomposites. J Nanosci Nanotechnol. 2015;15:8086–92.

Kesharwani P, Mishra V, Jain NK. Validating the anticancer potential of carbon nanotube-based therapeutics through cell line testing. Drug Discov Today. 2015;20:1049–60.

Morawska-Chochół A, Chłopek J, Szaraniec B, Domalik-Pyzik P, Balacha E, Boguń M, Kucharski R. Influence of the intramedullary nail preparation method on nail’s mechanical properties and degradation rate. Mater Sci Eng, C. 2015;51:99–106.

Kum CH, Cho Y, Seo SH, Joung YK, Ahn DJ, Han DK. A poly(lactide) stereocomplex structure with modified magnesium oxide and its effects in enhancing the mechanical properties and suppressing inflammation. Small. 2014;10:3783–94.

Ling LE, Feng L, Liu H-C, Wang D-S, Shi Z-P, Wang J-C, Luo W, Lv Y. The effect of calcium phosphate composite scaffolds on the osteogenic differentiation of rabbit dental pulp stem cells. J Biomed Mater Res A. 2016;103:1732–45.

Luo X, Barbier D, Duan R, Yuan H, Bruijn JD. Strontium-containing apatite/polylactide composites enhance bone formation in osteopenic rabbits. Acta Biomater. 2015;26:331–7.

Liu Z, Ji J, Tang S, Qian J, Yan Y, Yu B, Su J, Wei J. Biocompatibility, degradability, bioactivity and osteogenesis of mesoporous/macroporous scaffolds of mesoporous diopside/poly(L-lactide) composite. J R Soc Interface. 2015;12: Art. No. 20150507. doi:10.1098/rsif.2015.0507.

De Arenaza M, Sadaba N, Larrañaga A, Zuza E, Sarasua JR. High toughness biodegradable radiopaque composites based on polylactide and barium sulphate. Eur Polym J. 2015;73:88–93.

Maiti P, Yamada K, Okamoto M, Ueda K, Okamoto K. New polylactide/layered silica nanocomposites: role of organooclays. Chem Mater. 2002;14:4654–61.

Ray S, Yamada K, Ogami A, Okamoto M, Ueda K. New polylactide/layered silica nanocomposites: nanoscale control over multiple properties. Macromol Rapid Commun. 2002;23:943–7.

Ray S, Yamada K, Okamoto M, Ogami A, Ueda K. New polylactide/layered silica nanocomposites. 3. High-performance biodegradable materials. Chem Mater. 2003;15:1456–65.

Ojijo V, Ray S, Sadiku R. Concurrent enhancement of multiple properties in reactively processed nanocomposites of polylactide/poly[(butylene succinate)-co-adipate] blend and organoclay. Macromol Mater Eng. 2014;299:596–608.

Liao R, Yang B, Yu W, Zhou C. Isothermal cold crystallization kinetics of polylactide/nucleating agents. J Appl Polym Sci. 2007;104:310–7.

Kim HS, Park BH, Choi JH, Yoon JS. Mechanical properties and thermal stability of poly(L-lacitde)/calcium carbonate composites. J Appl Polym Sci. 2008;109:3087–92.

Gu SY, Zou CY, Zhou K, Ren J. Structure-rheology responses of polylactide/calcium carbonate composites. J Appl Polym Sci. 2009;114:1648–55.

Liu YS, Huang QL, Kienzle A, Müller WEG, Feng QL. In vitro degradation of porous PLLA/pearl powder composite scaffolds. Mater Sci Eng, C. 2014;38:227–34.

Fambri L, Migliaresi C. Crystalliztion and thermal properties. In: Auras RA, Lim L-T, Selke SEM, Tsuji H, editors. Poly(lactide acid):Synthesis, structure, properties, processing and applications. Hoboken: Wiley; 2010. p. 113–23. doi:10.1002/9780470649848.ch9.

Fischer EW, Sterzel HJ, Wegner G. Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reaction. Kolloid-Zu Z-Polym. 1973;251:980–90.

Gregorova A. Application of differential scanning calorimetry to the characterization of biopolymers. In: Elkordy AA, editor. Applications of calorimetry in a wide context—differential scanning calorimetry, isothermal titration calorimetry and microcalorimetry. InTech; 2013. pp. 3–20.

Thakur VK, Kessler MR. Green biorenewable biocomposites: from knowledge to industrial application. Boca Raton: CRC Press; 2015.

Khalaf MN. Effect of alkali lignin on heat of fusion crystallinity and melting points of low density polyethylene (LDPE), medium density polyethylene (MDPE) and high density polyethylene (HDPE). J Thi-Qar Sci. 2010;2:89–95.

Šumigin D, Tarasova E, Krumme A, Viikna A. Influence of cellulose content on thermal properties of poly(lactic) acid/cellulose and low-density polyethylene/cellulose composites. Proc Estonian Acad Sci. 2012;61:237–44.

Tábi T, Suplicz A, Czigány T. Thermal analysis of injection molded poly(lactic acid) filled with poly(ethylene glycol) and talc. J Therm Anal Calorim. 2014;118:1419–30.

Liu DY, Yuan XW, Bhattacharyya D, Easteal AJ. Characterisation of solution cast cellulose nanofibre—reinforced poly(lactic acid). eXPRESS Polym Lett. 2010;4:26–31.

Tábi T, Sajó IE, Szabó F, Luyt AS, Kovács JG. Crystalline structure of annealed polylactic acid and its relation to processing. eXPRESS Polym Lett. 2010;4:659–68.

Pluta M, Galeski A, Alexandre M, Paul MA, Dubois P. Polylactide/montmorillonite nanocomposites and microcomposites prepared by melt blending: structure and some physical properties. J Appl Polym Sci. 2002;86:1497–506.

Alexandre M, Beyer G, Henrist C, Cloots R, Rulmont A, Jérôme R, Dubois P. Preparation and properties of layered silicate nanocomposites based on ethylene vinyl acetate copolymers. Macromol Rapid Commun. 2001;22:643–6.

Degée P, Dubois P, Jérôme R. Bulk polymerization of lactides initiated by aluminium isopropoxide, 3. Thermal stability and viscoelastic properties. Macromol. Chem Phys. 1997;198:1985–95.

Mica Material Safety Data Sheet. http://www.erzkontor.com/cms/upload/documents/Material%20Safety%20Data%20Sheet%20Mica.pdf. Accessed 30 Jun 2015.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Vidović, E., Faraguna, F. & Jukić, A. Influence of inorganic fillers on PLA crystallinity and thermal properties. J Therm Anal Calorim 127, 371–380 (2017). https://doi.org/10.1007/s10973-016-5750-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5750-x