Abstract

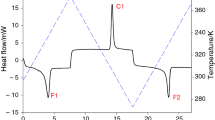

Poly(3-hydroxybutyrate) (PHB)/babassu compounds were prepared in a laboratory internal mixer with 10, 30, and 50 % by mass of fiber content. Nonisothermal melt crystallization behavior of PHB/babassu compounds was investigated using differential scanning calorimetry, and crystallization parameters were determined at cooling rates ranging between 2 and 32 °C min−1. Adding babassu fiber affected the melt crystallization behavior of PHB, and increasing filler content from 10 to 30 % has significant effects on the thermal characteristics of the system. Further increase in filler content from 30 to 50 % filler content has no effect on crystallization temperature and rate, but it has important positive consequences, once there is a considerably latitude in choosing the actual filler level in highly loaded PHB/babassu compounds without affecting processing characteristics. The melt crystallization kinetics of PHB/babassu compounds was analyzed by three empirical models widely used to represent nonisothermal polymer crystallization data: Pseudo-Avrami, Ozawa, and Mo. Kinetics analyses indicate that the Pseudo-Avrami model represented well the experimental data for both compounds in a wide interval of temperature, conversion, and cooling rates; the Ozawa model with two different sets of parameters, for low and high cooling rates, was found to correlate the data equally well, but over limited ranges of the variables, and the model proposed by Mo and collaborators did not adequately represent the experimental data for the systems and conditions tested.

Similar content being viewed by others

Abbreviations

- c :

-

Crystallization rate

- c 0.1–99.9% :

-

Crystallization rate measured between 0.1 and 99.9 % of mass transformation

- c 20–80% :

-

Crystallization rate measured between 20 and 80 % of mass transformation

- c max :

-

Maximum crystallization rate (at T c)

- E 0 :

-

Total latent heat released or absorbed by the sample during the crystallization or melting event

- F :

-

Mo rate parameter

- J :

-

DSC output heat flow rate of thermal energy exchanged between sample and the surroundings

- J 0 :

-

Virtual baseline during a phase change event

- K′:

-

Pseudo-Avrami rate parameter

- m :

-

Ozawa exponente

- MFR:

-

Melt flow rate

- M n :

-

Number average molar weight

- n′:

-

Pseudo-Avrami exponente

- t 1 :

-

Onset time of the crystallization event

- t 2 :

-

Endtime of the crystallization event

- T :

-

Temperature

- T 0.1% :

-

Temperature to attain 0.1 % of crystallized fraction

- T 50% :

-

Temperature to attain 50 % of crystallized fraction

- T 99.9% :

-

Temperature to attain 99.9 % of crystallized fraction

- T c :

-

Peak crystallization temperature

- T 0 :

-

Initial temperature on the start of the crystallization process

- X :

-

Relative crystallinity or crystallized fraction during a crystallization event

- X c :

-

Degree of crystallinity

- x(t):

-

Crystallized fraction as a function of time

- x(T):

-

Crystallized fraction as a function of temperature

- ∆H c :

-

Specific latent heat of crystallization

- \(\Delta H_{\text{m}}^{0}\) :

-

Equilibrium melting enthalpy of 100 % crystalline resin

- α :

-

Mo exponente

- ϕ :

-

Heating/cooling rate

- κ :

-

Ozawa rate parameter

- ρ :

-

Density

- τ :

-

Crystallization time

- τ ½ :

-

Crystallization halftime (time to attain 50 % fractional crystallization), inversely proportional to mean crystallization rate between 0 and 50 % fractional crystallization

References

Renstad R, Karlsson S, Albertsson A, Werner P, Westdahl M. Influence of processing parameters on the mass crystallinity of poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Polym Int. 1997;43:201–9.

Hocking PJ, Marchessault RH. Biopolymers (PHA). In: Griffin GJL, editor. Chemistry and technology of biodegradable polymers. London: Chapman & Hall/Backie; 1994.

Harding KG, Dennis JS, Blottnitz H, Harrison STL. Environmental analysis of plastic production processes: comparing petroleum-based polypropylene and polyethylene with biologically-based poly-β-hydroxybutyric acid using life cycle analysis. J Biotechnol. 2007;130:57–66.

Falcone DMB, Agnelli JAM, Faria LIL. Panorama Setorial e Perspectivas na Área de Polímeros Biodegradáveis. Polímeros: Ciências e tecnologia. 2007;17:5–9.

Reddy K, Ghai R, Kalia C. Polyhydroxyalkanoates: an overview. Bioresour Technol. 2003;87:137–46.

Hodzic A. Bacterial polyester-based biocompounds: a review. In: Mohanty AK, Misra M, Drzal LT, editors. Natural fibers, biopolymers, and biocompounds. Boca Raton: Taylor & Francis/CRC Press; 2005.

Rhim J, Park H, Ha C. Bio-nanocomposites for food packaging applications. Prog Polym Sci. 2014;38:1629–52.

Verhoogt H, Ramsay BA, Favis BD. Polymer blends containing poly(3-hydroxyalkanoate)s. Polymer. 1994;35:5155–69.

Wellen RMR, Canedo EL, Lima CAV, Araújo IC Jr, Almeida YMB. The effect of polystyrene on the crsytallization of poly(3-hydroxybutyrate). Mater Res. 2015;18:235–9.

Rosa DS, Chui QSH, Pantano FR, Agnelli JAM. Avaliação da biodegradação de poli-β-(Hidroxibutirato), poli-β-(hidroxibutirato-co-valeraro) e poli-β-(caprolactona) em solo compostado. Polímeros: Ciências e tecnologia. 2002;12:311–7.

Saad GR, Seliger H. Biodegradable copolymers based on bacterial poly((R)-3-hydroxybutyrate): thermal and mechanical properties and biodegradation behaviour. Polym Degrad Stab. 2004;83:101–10.

Sridewi N, Bhubalan K, Sudesh K. Degradation of commercially important polyhydroxyalkanoates in tropical mangrove ecosystem. Polym Degrad Stab. 2006;91:2931–40.

Abou-Zeid D, Müller R, Deckwer W. Degradation of natural and synthetic polyesters under anaerobic conditions. Biotechnology. 2001;86:113–26.

Chen G, Wu Q. The application of polyhydroxyalkanoates as tissue engineering materials. Biomaterials. 2005;26:6565–78.

El-Hadi A, Schnabel R, Straube E, Müller G, Riemschneider M. Effect of melt processing on crystallization behavior and rheology of poly(3-hydroxybutyrate) (PHB) and its blends. Macromol Mater Eng. 2002;287:363–72.

Andrade ALS. Estudo da estabilidade térmica em processamento de PHB com aditivo extensor de cadeia. Federal University of Campina Grande, Department of Materials Engineering, MSc Thesis. 2014.

Gogolewski S, Jonanovic M, Perren SM, Dillon JG, Hughes MK. The effect of melt-processing on the degradation of selected polyhydroxyacids: polylactides, polyhydroxybutyrate, and polyhydroxybutyrate-co-valerates. Polym Degrad Stab. 1993;40:313–22.

Cipriano, PB. Estudo de compósitos biodegradáveis PHB/fibras vegetais. Federal University of Campina Grande, Department of Materials Engineering, MScThesis. 2012.

Carrazza LR, Ávila JCC, Silva ML. Aproveitamento Integral do fruto e da folha do babaçu (Attaleaspp), 2a. Edição. Material Tecnológico 5, ISPN, Brasília DF, 2012.

Barham PJ, Keller A, Otun EL, Holmes PA. Crystallization and morphology of a bacterial thermoplastic: poly-3-hydroxybutyrate. J Mater Sci. 1984;19:2781–9.

An Y, Dong L, Mo Z, Liu T, Feng Z. Nonisothermal crystallization kinetics of poly(β-hydoxybutyrate). J Polym Sci Part B: Polym Phys. 1998;36:1305–12.

Machado MLC, Pereira NC, Miranda LF, Terence MC, Pradella JGC. Study of mechanical and thermal properties of the polymer poly-3-hydroxybutyrate (PHB). Polímeros Ciência e Tecnologia. 2010;20:65–71.

Xue M, Sheng J, Yu Y, Chuah HH. Nonisothermal crystallization kinetics and spherulite morphology of poly(trimethylene terephthalate). Eur Polym J. 2004;40:811–8.

Ozawa T. Kinetics of non-isothermal crystallization. Polymer. 1971;12:150–8.

Liu T, Mo Z, Wang S, Zhang H. Noinsothermal melt and cold crystallization kinetics of poly (Aryl Ether Ether Ketone Ketone). Polym Eng Sci. 1997;37:568–75.

Liu T, Mo Z, Zhang H. Nonisothermal crystallization behavior of a novel poly(aryl ether ketone): PEDEKmK. J Appl Polym Sci. 1998;67:815–21.

Avrami M. Kinetics of phase change. I. General model. J Chem Phys. 1939;7:1103–12.

Avrami M. Kinetics of phase change. II. Transformation-time relations for random distribution of nuclei. J Chem Phys. 1940;8:212–24.

Avrami M. Kinetics of phase change. III. Granulation, phase change, and microstructure. J Chem Phys. 1941;9:177–84.

Biocycle 1000 Technical Data Sheet. PHB Industrial S/A, 2014.

Schultz JM. Polymer crystallization. In: The Development of Crystalline Order in Thermoplastic Polymers. Washington DC (USA)/Oxford (UK): American Chemical Society/Oxford University Press: 2001.

Zhou H, Ying J, Xie X, Liu F, Li D. Nonisothermal crystallization behavior and kinetics of isotactic polypropylene/ethylene–octene blends. Part II: modeling of crystallization kinetics. Polym Test. 2010;29:915–23.

Pearce R, Brown RG, Marchessault RH. Crystallization kinetics in blends of isotactic and atactic poly(ß-hydroxybutyrate). Polymer. 1994;35:3984–9.

Zhao L, Kai W, He Y, Zhu B, Inoue Y. Effect of aging on fractional crystallization of poly(ethylene oxide) component in poly(ethylene oxide)/poly(3-hydroxybutyrate) blends. J Polym Sci, Part B: Polym Phys. 2005;43:2665–76.

Panine P, Di Cola E, Sztucki M, Narayanan T. Early stages of polymer melt crystallization. Polymer. 2008;49:675–80.

Li B, Yu J, Lee S, Ree M. Crystallizations of poly(ethylene terephthalate co ethylene isophthalate). Polymer. 1999;40:5371–5.

Zheng L, Wang YZ, Yang KK, Wang XL, Chen SC, Li J. Effect of PEG on the crystallization of PPDO/PEG blends. Eur Polym J. 2005;41:1243–50.

Achilias DS, Papageorgiou GZ, Karayannidis GP. Isothermal and nonisothermal crystallization kinetics of poly(propylene terephthalate). J Polym Sci, Part B: Polym Phys. 2004;42:3775–96.

Aziz MSA, Naguib HF, Saad GR. Non-isothermal crystallization kinetics of bacterial poly(3-hydroxybutyrate) in poly(3-hydroxybutyrate-co-butylene adipate) urethanes. Thermochim Acta. 2014;591:130–9.

Eder M, Wlochowicz A. Kinetics of non-isothermal crystallization of polyethylene and popropylene. Polymer. 1983;24:1593–5.

Chen T, Zhang J. Non-isothermal cold crystallization kinetics of poly(ethylene glycol-co-1,4-cyclohexanedimethanol terephthalate) (PETG) copolyesters with different compositions. Polym Test. 2015;48:23–30.

Wan J, Bu Z, Li C, Fan H, Li B. Preparation, melting, glass relaxation and nonisothermal crystallization kinetics of a novel dendritic nylon-11. Thermochim Acta. 2011;524:117–27.

He M, Zong S, Zhou Y, Guo H, Fan Q. Non-isothermal crystallization kinetics of reactive microgel/nylon 6 blends. Chin J Chem Eng. 2015;23:1403–7.

Aziz MSA, Saad GR. HF. Naguib. Non-isothermal crystallization kinetics of poly(3-hydroxybutyrate) in copoly(ester-urethane) nanocomposites based on poly(3- hydroxybutyrate) and cloisite 30B. Thermochim Acta. 2015;605:52–62.

Deshmukh GS, Peshwe DR, Pathak SU, Ekhe JD. Nonisothermal crystallization kinetics and melting behavior of poly (butylene terephthalate) and calcium carbonate nanocomposites. Thermochim Acta. 2015;606:66–76.

Liu H, Ma J, Gong J, Xu J. The effect of Pglass state on the non-isothermal cold and melt crystallization processes of PET matrix. Thermochim Acta. 2015;613:1–8.

Acknowledgements

The authors are indebted to CNPq (Brasília/DF, Brazil) and FACEPE (Recife/Pernambuco, Brazil) for the financial support and to PHB Industrial (Serrana/São Paulo, Brazil) and MAPA Representations (São Luis/Maranhão, Brazil), respectively, for the donation of polymer and filler.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vitorino, M.B.C., Cipriano, P.B., Wellen, R.M.R. et al. Nonisothermal melt crystallization of PHB/babassu compounds. J Therm Anal Calorim 126, 755–769 (2016). https://doi.org/10.1007/s10973-016-5514-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5514-7