Abstract

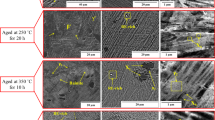

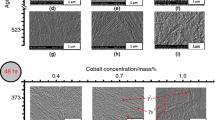

The present work aims to investigate the aging treatment effects on the microstructure, transition characteristics, and mechanical properties of Cu–Al–Ni–xTi shape memory alloys. The aging treatment of the homogenized and modified alloys of Cu–Al–Ni–xTi results in variations of the martensite morphology, volume fraction, and precipitate size. These variations in the features of precipitates have an obvious effect on transition behavior and mechanical properties. The transition temperatures are increased slightly with an increase in the aging time and temperatures; such increase is mainly attributed to changes in the γ′1 and β′1 morphology and distribution, along with the precipitates. The thermodynamic parameters (ΔH and ΔS) tend to decrease with an increase in the aging time and temperatures. Moreover, the brittleness, low strength, and poor processability of Cu–Al–Ni alloys greatly limit their application. We attempted to improve the mechanical properties without losing the thermoelastic properties through the additions of Ti and appropriate aging treatments. The highest tensile strength and strain of 640 MPa and 4.3 % were obtained in alloy of Cu–Al–Ni-0.7 mass% Ti aged at 250 °C for 24 h and 100 °C for 48 h, respectively. The shape memory behavior of the alloys was studied using a specially designed machine. The strain recovery by shape memory effect of the alloys increases with an increase in the aging tomes and temperature, where the highest recovery (100 %) is obtained with the alloy of Cu–Al–Ni-0.7 mass% Ti after being aged at 250 °C for 24 h.

Similar content being viewed by others

References

Gandhi V, Thompson BS. Smart materials and structures. London: Springer; 1992.

Otsuka K, Wayman CM. Shape memory materials. Reprint, illustrated ed. Cambridge: Cambridge University Press; 1999.

Vokoun D, Kafka V, Mesomechanical modeling of shape memory effect. In: Symposium on smart structures and materials: International Society for Optics and Photonics; 1999

Kumar P, Lagoudas D. Introduction to shape memory alloys. Berlin: Springer; 2008.

Nishiyama Z, Fine ME, Wayman CM. Martensitic transformation. London: Academic Press; 1978.

Ibarra A, Juan JS, Bocanegra EH, Nó ML. Thermo-mechanical characterization of Cu–Al–Ni shape memory alloys elaborated by powder metallurgy. Mater Sci Eng A. 2006;438–440:782–6.

Recarte V, Pérez-Landazábal JI, Nó ML, San Juan J. Study by resonant ultrasound spectroscopy of the elastic constants of the β phase in Cu–Al–Ni shape memory alloys. Mater Sci Eng A. 2004;370(1–2):488–91. doi:10.1016/j.msea.2003.06.004.

Font J, Cesari E, Muntasell J, Pons J. Thermomechanical cycling in Cu–Al–Ni-based melt-spun shape-memory ribbons. Mater Sci Eng A. 2003;354(1–2):207–11.

Pérez-Landazábal JI, Recarte V, Sánchez-Alarcos V, Nó ML, Juan JS. Study of the stability and decomposition process of the β phase in Cu–Al–Ni shape memory alloys. Mater Sci Eng A. 2006;438–440:734–7. doi:10.1016/j.msea.2005.12.066.

Mukunthan K, Brown L. Preparation and properties of fine grain β-CuAlNi strain-memory alloys. Metall Trans A. 1988;19(12):2921–9.

Saud S, Hamzah E, Abubakar T, Bakhsheshi-Rad HR. Thermal aging behavior in Cu–Al–Ni–xCo shape memory alloys. J Therm Anal Calorim. 2015;119(2):1273.

Saud S, Hamzah E, Abubakar T, Zamri M, Tanemura M. Influence of Ti additions on the martensitic phase transformation and mechanical properties of Cu–Al–Ni shape memory alloys. J Therm Anal Calorim. 2014;118(1):111–22.

Saud S, Hamzah E, Abubakar T, Bakhsheshi-Rad HR, Zamri M, Tanemura M. Effects of Mn additions on the structure, mechanical properties, and corrosion behavior of Cu–Al–Ni shape memory alloys. J Mater Eng Perform. 2014;23(10):3620–29.

Yildiz K, Kok M. Study of martensite transformation and microstructural evolution of Cu–Al–Ni–Fe shape memory alloys. J Therm Anal Calorim. 2014;115(2):1509–14.

Balo ŞN, Sel N. Effects of thermal aging on transformation temperatures and some physical parameters of Cu–13.5 wt%Al–4 wt%Ni shape memory alloy. Thermochim Acta. 2012;536:1–5.

Sobrero CE, La Roca P, Roatta A, Bolmaro RE, Malarría J. Shape memory properties of highly textured Cu–Al–Ni–(Ti) alloys. Mater Sci Eng A. 2012;536:207–15.

Sinha A, Mondal B, Chattopadhyay PP. Mechanical properties of Ti–(∼49 at%) Ni shape memory alloy, part II: effect of ageing treatment. Mater Sci Eng A. 2013;561:344–51.

Lagoudas DC. Shape memory alloys: modeling and engineering applications. Berlin: Springer; 2008.

Imran Khan M, Kim HY, T-h Nam, Miyazaki S. Formation of nanoscaled precipitates and their effects on the high-temperature shape-memory characteristics of a Ti50Ni15Pd25Cu10 alloy. Acta Mater. 2012;60(16):5900–13.

Picornell C, Pons J, Cesari E. Effects of thermal ageing in β-phase in Cu–Al–Ni single crystals. J Phys IV. 1997;7(C5):C5-323-C5-8.

Zarubova N, Gemperle A, Novak V. Initial stages of γ2 precipitation in an aged Cu–Al–Ni shape memory alloy. Mater Sci Eng A. 1997;222(2):166–74.

Zarubova N, Gemperle A, Novak V. Ageing Phenornena in a Cu–Al–Ni Alloy. J Phys IV. 1997;7(C5):C5-281-C5-6.

Guenin P. Thermal aging behaviour and origin of a Cu–Al–Ni shape memory alloy. Mater Sci Eng A. 1990;129:273–7.

Daricek T, Lasek J, Zarubova N, Novak V, Bartuska P. Ageing effects in a Cu–Al–Ni shape memory alloy. J Phys IV. 2001;11(PR8):Pr8-179-Pr8-84.

Tarhan EF. Aging characteristics of copper based shape memory alloys. Middle East Technical University; 2004.

Bouabdallah M, Baguenane-Benalia G, Saadi A, Cheniti H, Gachon J-C, Patoor E. Precipitation sequence during ageing in β1 phase of Cu–Al–Ni shape memory alloy. J Therm Anal Calorim. 2013;112(1):279–83.

Suresh N, Ramamurty U. Aging response and its effect on the functional properties of Cu–Al–Ni shape memory alloys. J Alloy Compd. 2008;449(1–2):113–8.

Tatar C. Gamma irradiation-induced evolution of the transformation temperatures and thermodynamic parameters in a CuZnAl shape memory alloy. Thermochim Acta. 2005;437:121–5.

Ortín J, Planes A. Thermodynamics of thermoelastic martensitic transformations. Acta Metall. 1989;37(5):1433–41.

Xuan Q, Bohong J, Hsu TY. The effect of martensite ordering on shape memory effect in a copper–zinc–aluminium alloy. Mater Sci Eng. 1987;93:205–11.

Roh DW, Kim JW, Cho TJ, Kim YG. Tensile properties and microstructure of microalloyed Cu-A1-Ni-X shape memory alloys. Mater Sci Eng A. 1991;136:17–23.

Khan A, Delaey L. The effect of grain size on the strength of Cu–Al Beta’-martensite. Z Metallkd. 1969;60(12):949–51.

Dogan E. CoNiGa high temperature shape memory alloys. Texas A&M University; 2010.

Otsuka K, Ren X. Recent developments in the research of shape memory alloys. Intermetallics. 1999;7(5):511–28.

Ma Y, Yang S, Wang C, Liu X. Tensile characteristics and shape memory effect of Ni56Mn21Co4Ga19 high-temperature shape memory alloy. Scripta Mater. 2008;58(10):918–21.

Yang JP, Kim YG. Tensile properties and shape memory effect of chromium-varied Fe30Mn5SiCr shape memory alloys. Mater Sci Eng A. 1992;154(1):L1–3.

Duerig T, Pelton A. Ti-Ni shape memory alloys. In: Boyer R, Collings EW, Welsch G, editors. Materials properties handbook: titanium alloys. USA: ASM International; 1994. pp. 1035–48.

Ma Y, Yang S, Liu Y, Liu X. The ductility and shape-memory properties of Ni–Mn–Co–Ga high-temperature shape-memory alloys. Acta Mater. 2009;57(11):3232–41.

Acknowledgements

The author(s) would like to thank the Malaysian Ministry of Higher Education (MOHE) and Universiti Teknologi Malaysia for providing the financial support and facilities for this research, under Grant No. R.J130000.7824.4F150.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saud, S.N., Hamzah, E., Abubakar, T. et al. X-phase precipitation in aging of Cu–Al–Ni–xTi shape memory alloys and its influence on phase transition behavior. J Therm Anal Calorim 123, 377–389 (2016). https://doi.org/10.1007/s10973-015-4894-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4894-4