Abstract

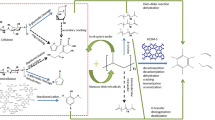

The present research work focuses on understanding the kinetics and mechanism of co-pyrolysis of cellulose, a major constituent of biomass, and polypropylene (PP) that is abundantly present in waste plastics. Co-pyrolysis of cellulose and PP of different compositions, viz., 100:0, 80:20, 60:40, 40:60, 20:80, and 0:100 (mass%/mass%), was carried out in a thermogravimetric analyzer at various heating rates from 5 to 180 K min−1. The kinetics of slow to medium heating rate pyrolysis was analyzed using first Kissinger and Kissinger–Akahira–Sunose techniques. Cellulose and PP decomposition occurred in two distinct temperature regimes, viz., 575–650 and 675–775 K, respectively. However, apparent activation energies of thermal decomposition of the mixtures clearly indicated the presence of interaction between cellulose and PP. The presence of cellulose in the mixture decreased the apparent activation energy of PP decomposition from 210 to 120 kJ mol−1, while the presence of PP did not affect the apparent activation energy of cellulose decomposition (E a = 158 ± 3 kJ mol−1). A significant decrease in apparent activation energy was observed in the conversion regime corresponding to the completion of cellulose pyrolysis and beginning of PP pyrolysis. Differential scanning calorimetry data clearly showed the shift of exothermic char formation to higher temperatures with PP incorporation in the mixture. The presence of PP also resulted in reduction of final char content. Based on the above analyses, a new interaction step that involves a bimolecular reaction of activated PP with volatiles from cellulose pyrolysis to form interaction products and char is proposed, and the rate limiting steps for char formation are clearly identified.

Similar content being viewed by others

References

Brown RC. Thermochemical processing of biomass conversion into fuels, chemicals and power. 1st ed. Chichester: Wiley; 2011.

Ranzi E, Cuoci A, Faravelli T, Frassoldati A, Migliavacca G, Pierucci S, Sommariva S. Chemical kinetics of biomass pyrolysis. Energy Fuels. 2008;22:4292–300.

Dauenhauer PJ, Colby JL, Balonek CM, Suszyuski WJ, Schmidt LD. Reactive boiling of cellulose for integrated catalysis through an intermediate liquid. Green Chem. 2009;11:1555–61.

Teixeira AR, Mooney KG, Kruger JS, Williams CL, Suszynski WJ, Schmidt LD, Schmidt DP, Dauenhauer PJ. Aerosol generation by reactive boiling ejection of molten cellulose. Energy Environ Sci. 2011;4:4306–21.

Lin YC, Cho J, Tompsett GA, Westmoreland PR, Huber GW. Kinetics and mechanism of cellulose pyrolysis. J Phys Chem C. 2009;113:20097–107.

Mamleev V, Bourbigot S, Bras ML, Yvon J. The facts and hypothesis relating to the phenomenological model of cellulose pyrolysis. Interdependence of steps. J Anal Appl Pyrol. 2009;84:1–17.

Mettler MS, Mushrif SH, Paulsen AD, Javadekar AD, Vlachos DG, Dauenhauer PJ. Revealing pyrolysis chemistry for biofuels production: conversion of cellulose to furans and small oxygenates. Energy Environ Sci. 2012;5:5414–24.

Vinu R, Broadbelt LJ. A mechanistic model of fast pyrolysis of glucose-based carbohydrates to predict bio-oil composition. Energy Environ Sci. 2012;5:9808–26.

Kruse TM, Wong HW, Broadbelt LJ. Mechanistic modeling of polymer degradation: polypropylene. Macromolecules. 2003;36:9594–607.

Marongiu A, Faravelli T, Ranzi E. Detailed kinetic modeling of the thermal degradation of vinyl polymers. J Anal Appl Pyrol. 2007;78:343–62.

Wooten JB, Seeman JI, Hajaligol MR. Observation and characterization of cellulose pyrolysis intermediates by 13C CPMAS NMR. A new mechanistic model. Energy Fuels. 2004;18:1–15.

Di Blasi C. Linear pyrolysis of cellulose and plastic waste. J Anal Appl Pyrol. 1997;40–41:463–79.

Jakab E, Blazsó M, Faix O. Thermal decomposition of mixtures of vinyl polymers and lignocellulosic materials. J Anal Appl Pyrol. 2001;58–59:49–62.

Cao Q, Jin L, Bao W, Lv Y. Investigations into the characteristics of oils produced from co-pyrolysis of biomass and tire. Fuel Process Technol. 2009;90:337–42.

Ye JL, Cao Q, Zhao YS. Co-pyrolysis of polypropylene and biomass. Energy Source Part A. 2008;30:1689–97.

Park HJ, Heo HS, Yoo KS, Yim JH, Sohn JM, Jeong KE, Jeon JK, Park YK. Thermal degradation of plywood with block polypropylene in TG and batch reactor system. J Ind Eng Chem. 2011;17:549–53.

Aydinli B, Caglar A. The investigation of the effects of two different polymers and three catalysts on pyrolysis of hazelnut shell. Fuel Process Technol. 2012;93:1–7.

Sharypov VI, Marin N, Beregovtsova NG, Baryshnikov SV, Kuznetsov BN, Cebolla VL, Weber JL. Co-pyrolysis of wood biomass and synthetic polymer mixtures. Part I: influence of experimental conditions on the evolution of solids, liquids and gases. J Anal Appl Pyrol. 2002;64:15–28.

Marin N, Collura S, Sharypov VI, Beregovtsova NG, Baryshnikov SV, Kuznetsov BN, Cebolla VL, Weber JV. Co-pyrolysis of wood biomass and synthetic polymers mixtures. Part II: Characterisation of liquid phases. J Anal Appl Pyrol. 2002;65:41–55.

Sharypov VI, Beregovtsova NG, Kuznetsov BN, Membrado L, Cebolla VL, Marin N, Weber JV. Co-pyrolysis of wood biomass and synthetic polymers mixtures. Part III: characterisation of heavy products. J Anal Appl Pyrol. 2003;67:325–40.

Aboulkas A, El Harfi K, Nadifiyine M, El Bouadili A. Thermogravimetric characteristics and kinetic of co-pyrolysis of olive residue with high density polyethylene. J Therm Anal Calorim. 2008;91:737–43.

Aboulkas A, El Harfi K. Co-pyrolysis of olive residue with poly(vinyl chloride) using thermogravimetric analysis. J Therm Anal Calorim. 2009;95:1007–13.

Han B, Chen Y, Wu Y, Hua D, Chen Z, Feng W, Yang M, Xie Q. Co-pyrolysis behaviors and kinetics of plastics–biomass blends through thermogravimetric analysis. J Therm Anal Calorim. 2014;115:227–35.

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520:1–19.

Sbirrazzuoli N, Vincent L, Mija A, Guigo N. Integral, differential and advanced isoconversional methods. Complex mechanisms and isothermal predicted conversion-time curves. Chemom Intell Lab Syst. 2009;96:219–26.

Conesa JA, Caballero JA, Marcilla A, Font R. Analysis of different kinetic models in the dynamic pyrolysis of cellulose. Thermochim Acta. 1995;254:175–92.

Kim HT, Oh SC. Kinetics of thermal degradation of waste polypropylene and high-density polyethylene. J Ind Eng Chem. 2005;11:648–56.

Dahiya JB, Kumar K, Muller-Hagedorn M, Bockhorn H. Kinetics of isothermal and non-isothermal degradation of cellulose: model-based and model-free methods. Polym Int. 2008;57:722–9.

Simon P. Isoconversional methods: fundamentals, meaning and application. J Therm Anal Calorim. 2004;76:123–32.

Westerhout RWJ, Waanders J, Kuipers JAM, van Swaaij WPM. Kinetics of the low-temperature pyrolysis of polythene, polypropene, and polystyrene modelling, experimental determination, and comparison, and comparison with literature models and data. Ind Eng Chem Res. 1997;36:1955–64.

Milosavljevic I, Suuberg EM. Cellulose thermal decomposition kinetics: Global mass loss kinetics. Ind Eng Chem Res. 1995;34:1081–91.

Gronli M, Antal MJ Jr, Várhegyi G. A round-robin study of cellulose pyrolysis kinetics by thermogravimetry. Ind Eng Chem Res. 1999;38:2238–44.

Antal MJ, Várhegyi G. Cellulose pyrolysis kinetics: Revisited. Ind Eng Chem Res. 1998;37:1267–75.

Mark JE. Polymer data handbook. New York: Oxford University Press; 1999.

Cho J, Davis JM, Huber GW. The intrinsic kinetics and heats of reactions for cellulose pyrolysis and char formation. ChemSusChem. 2010;3:1162–5.

Di Blasi C. Comparison of semi-global mechanisms for primary pyrolysis of lignocellulosic fuels. J Anal Appl Pyrol. 1998;47:43–64.

Brewer CE, Schmidt-Rohr K, Satrio JA, Brown RC. Characterization of biochar from fast pyrolysis and gasification systems. Environ Prog Sustain Energy. 2009;28:386–96.

Acknowledgements

The authors thank Department of Science and Technology (DST), India, for funding to procure TG analyzer via FIST grant. R.V. thanks Indian Institute of Technology Madras for new faculty seed grant, and DST, India, for project funding. The National Center for Combustion Research and Development is sponsored by DST, India.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Suriapparao, D.V., Ojha, D.K., Ray, T. et al. Kinetic analysis of co-pyrolysis of cellulose and polypropylene. J Therm Anal Calorim 117, 1441–1451 (2014). https://doi.org/10.1007/s10973-014-3866-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-3866-4