Abstract

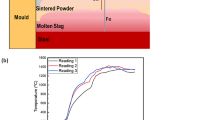

By exploring the effects of carbon equivalent (CE = 3.4–4.2%) and inoculation (Ca, Ba, Al–FeSi alloy), the thermal analysis parameters, representative temperatures and undercooling events, during solidification of cast irons are compared with chill tendency (carbides) in cast irons. Cooling curve analyses were conducted directly in the thermal centre of samples solidified in resin sand and metal moulds to explore the utility of thermal analysis in actual casting shapes. As a reference, a Quik-cup™ system was employed with the same cooling modulus (CM = 0.75 cm). The austenite formation temperature is lower at higher CE, with higher temperatures of both the start of the eutectic reaction and end of solidification. This was more pronounced for metal mould solidification and for un-inoculated irons, respectively. The transition from white iron through mottled iron up to grey iron macrostructure is illustrated by variations of eutectic undercooling compared to the metastable equilibrium temperature, as affected by increasing carbon equivalent and applied inoculation. Inoculation affected both austenite and eutectic formation, by preventing excess eutectic undercooling during solidification, even at low carbon equivalent. The differences in solidification patterns of sand and metal mould castings are discussed, for un-inoculated and inoculated irons, at different carbon equivalent values.

Similar content being viewed by others

References

Jiyang Zhou. Colour metallography of cast iron. China Foundry. 2009;6(1):57–69.

Nakae H. Influence of inoculation on solidification in cast iron. Int J Cast Met Res. 2008;21(1–4):7–10.

Sun XJ, Li YX. Influence of duplex melting process on melt quality and solidification of grey cast iron. Int J Cast Met Res. 2007;20(5):240–5.

Riposan I, Chisamera M, Stan S, Hartung C, White D. Three-stage model for the nucleation of graphite in grey cast iron. Mater Sci Technol. 2010;26(12):1439–47.

Chisamera M, Riposan I, Stan S, Stefan E, Costache C. Thermal analysis control of in-mould and ladle inoculated grey cast irons. China Foundry. 2009;6(2):145–51.

Fras E, Gorny M, Lopez HF. The transition from gray to white cast iron during solidification: Part III. Thermal analysis. Metall Mater Trans A. 2005;36A(11):3093–101.

Li YX, Hu X, Xu XR. Pattern recognition of thermal analysis cooling curves and quality evaluation of melt cast alloys. J Mater Sci Technol. 2001;17(1):73–4.

Stefanescu DM. Honorary Lecture: Cooling Curve Analysis—A Mature Melt Quality Control Technique. In: Proc. 115th AFS Metalcasting Congr., 5–8 Apr 2011, Schaumburg, Illinois, USA. Paper 11–128.

Dioszegi A, Svensson IL. On the problems of thermal analysis of solidification. Mater Sci Eng A. 2005;413–414:474–9.

Dioszegi A, Svensson IL. Interpretation of solidification by thermal analysis of cooling rate. Trans Indian Inst Met. 2005;58(4):611–6.

Dioszegi A, Hattel J. Inverse thermal analysis method to study solidification in cast iron. Int J Cast Met Res. 2004;17(5):311–8.

Van Ettinger CJ, Baumgert W. Thermal Analysis, An Unique Fingerprint of a Melt. In: Proc. 66th World Foundry Congress, Sept 2004, Istanbul, Turkey. p. 743–56.

Degirmenci S, Gunay Y, Metan I, Sirin B. The New Application of Adaptive Thermal Analysis System (ATAS) on Gray and Ductile Cast Iron Production. In: Proc. 66th World Foundry Congress, Sept 2004, Istanbul, Turkey. p. 757–74.

Cetin A, Kalkanli A. Computer-Aided Thermal Analysis of Gray Cast Iron by Using Cooling Curves. In: Proc. 66th World Foundry Congress, Sept 2004, Istanbul, Turkey. p. 837–48.

Emadi D, Whiting LV, Nafisi S, Ghomashchi R. Applications of thermal analysis in quality control of solidification processes. J Therm Anal Calorim. 2005;81:235–42.

Mahfoud M, Emadi D. Application of heat pipe technology in thermal analysis of metals. J Therm Anal Calorim. 2005;81:161–7.

Malekan M, Shabestari SG. Computer-aided cooling curve thermal analysis used to predict the quality of aluminum alloys. J Therm Anal Calorim. 2011;103:453–8.

Mahfoud M, Prasado Rao AK, Emadi D. The role of thermal analysis in detecting impurity levels during aluminum recycling. J Therm Anal Calorim. 2010;100:847–51.

Gundlach R. Observations on Structure Control to Improve the Properties of Cast Irons. The 2008 Honorary Cast Iron Lecture, Div. 5, AFS Metalcasting Congress, Atlanta, Georgia, USA; 2008. Paper 08–158.

Riposan I, Chisamera M, Stan S, Ecob C, Wilkinson D. Role of Al, Ti, and Zr in gray iron preconditioning/inoculation. J Mater Eng Perform. 2009;18(1):83–7.

American Society for Testing of Materials, Standard A367-85: Standard Test Methods of Chill Testing of Cast Iron, 1 Feb 2000, West Conshohocken, PA. p. 151–154.

Stan S, Chisamera M, Riposan I, Stefan E, Barstow M. Solidification pattern of un-inoculated and inoculated gray cast irons in wedge test samples. AFS Trans. 2010;118:295–309.

Sillen R V. Optimizing Inoculation Practice by means of Thermal Analysis. In: Proc. AFS International Inoculation Conf., 6–8 Apr 1998, Rosemont, Illinois, USA.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stan, S., Chisamera, M., Riposan, I. et al. Application of thermal analysis to monitor the quality of hypoeutectic cast irons during solidification in sand and metal moulds. J Therm Anal Calorim 110, 1185–1192 (2012). https://doi.org/10.1007/s10973-011-2128-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-2128-y