Abstract

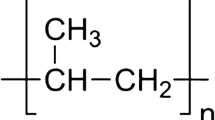

Non-isothermal crystallization kinetics of the ethylene–acrylic acid copolymer (EAA) in diluents during thermally induced phase separation (TIPS) process was investigated via differential scanning calorimetry (DSC). Dioctyl phthalate (DOP), diphenyl ester (DPE), and peanut oil were used as diluents. Kinetic models, such as Jeziorny theory, Ozawa theory, and Mo’s approach, were utilized for description. The effective activation energy of EAA component in mixture was calculated by Friedman’s method. In the results, the Jeziorny theory and Mo’s approach could obtain good linear fitting relationship with the primary crystallization behavior of EAA, but the Ozawa theory failed to get a suitable result. The homogeneous nucleation of EAA proceeded at the end of liquid–liquid phase separation, while the non-isothermal crystallization developed within a solid–liquid phase separation environment. In the mixtures, the molecular weight, polar groups, and conformation of the diluent molecules would affect the nucleation of EAA, and its growth rate. Comparing with the non-isothermal crystallization of neat EAA, EAA in diluents obtained a higher Avrami index n, and comparatively lower crystallization rate. Peanut oil facilitated the homogeneous nucleation of EAA, leading to a higher melting peak temperature of EAA in the subsequent melting endotherms. The largest EAA’s Avrami index obtained in peanut oil also indicated a higher crystal growth dimensional geometry. The crystallization rate and crystallinity of EAA during the non-isothermal process decreased in the sequence: EAA/DPE > EAA/DOP > EAA/peanut oil.

Similar content being viewed by others

References

Lim GBA, Kim SS, Ye Q, Wang YF, Lloyd DR. Microporous membrane formation via thermally induced phase separation. IV. Effect of isotactic polypropylene crystallization kinetics on membrane structure. J Membr Sci. 1991;64(1–2):31–40.

Yang MC, Perng JS. Microporous polypropylene tubular membranes via thermally induced phase separation using a novel solvent-camphene. J Membr Sci. 2001;187(1):13–22.

Baltus RE. Characterization of the pore area distribution in porous membranes using transport measurements. J Membr Sci. 1997;123(2):165–84.

Hollman AM, Scherrer NT, Cammers-Goodwin A, Bhattacharyya D. Separation of dilute electrolytes in poly(amino acid) functionalized microporous membranes: model evaluation and experimental results. J Membr Sci. 2004;239(1):65–79.

Jeon MY, Kim CK. Phase behavior of polymer/diluent/diluent mixtures and their application to control microporous membrane structure. J Membr Sci. 2007;300(1–2):172–81.

Nunes SP, Peinemann KV. Ultrafiltration membranes from PVDF/PMMA blends. J Membr Sci. 1992;73(1):25–35.

Ochoa NA, Masuelli M, Marchese J. Effect of hydrophilicity on fouling of an emulsified oil wastewater with PVDF/PMMA membranes. J Membr Sci. 2003;226(1–2):203–11.

Gu MH, Zhang J, Wang XL, Tao HJ, Ge LT. Formation of poly(vinylidene fluoride) (PVDF) membrane via thermally induced phase separation. Desalination. 2006;192(11):160–7.

Wang S, Torkeson JM. Coarsening effects on the formation of microporous membrane produced via thermally induced phase separation of polystyrene-cyclohexanol solutions. J Membr Sci. 1995;98(3):209–22.

Shang MX, Matsuyama H, Teramotoa M. Preparation and membrane performance of poly(ethylene-co-vinylalcohol) hollow fiber membrane via thermally induced phase separation. Polymer. 2003;44(24):7441–7.

Zhou J, Yin J, Lv R, Du Q, Zhong W. Preparation and properties of MPEG-grafted EAA membranes via thermally induced phase separation. J Membr Sci. 2005;267(1–2):90–8.

Zhou J, Lin Y, Du Q, Zhong W, Wang H. Effect of MPEG on MPEG-grafted EAA membrane formation via thermally induced phase separation. J Membr Sci. 2006;283(1–2):310–9.

Kolesov IS, Androsch R, Radusch HJ. Non-isothermal crystallization of polyethylenes as function of cooling rate and concentration of short chain branches. J Therm Anal Calorim. 2004;78(3):885–95.

Parasnis NC, Ramani K. Non-isothermal crystallization of UHMWPE. J Therm Anal Calorim. 1999;55(3):709–19.

Vyazovkin S, Sbirrazzuoli N. Estimating the activation energy for non-isothermal crystallization of polymer melts. J Therm Anal Calorim. 2003;72(2):681–6.

Alvarez VA, Stefani PM, Vazquez A. Non-isothermal crystallization of polyvinylalcohol-co-ethylene. J Therm Anal Calorim. 2005;79(1):187–93.

Zhang J, Chen SJ, Su J, Shi XM, Jin J, Wang XP, et al. Non-isothermal crystallization kinetics and melting behavior of EAA with different acrylic acid content. J Therm Anal Calorim. 2009;97(3):959–67.

Gu MH, Zhang J, Wang XL. Crystallization behavior of PVDF in PVDF-DMP system via thermally induced phase separation. J Appl Polym Sci. 2006;102(4):3714–9.

Tao HJ, Zhang J, Wang XL. Phase separation, polymer crystallization in TPX-DOS -DMP system via thermally induced phase separation. J Polym Sci B. 2007;45(2):153–61.

Brandrup J, Immergut EH. Polymer handbook. New York: Wiley; 1999.

Lloyd DR, Kim SS, Kinzer KE. Microporous membrane formation via thermally induced phase separation. II. Liquid–liquid phase separation. J Membr Sci. 1991;64(1–2):1–11.

Matsuyama H, Maki T, Teramoto M. Effect of polypropylene molecular weight on porous membrane formation by thermally induced phase separation. J Membr Sci. 2002;204(1–2):323–8.

McGuire KS, Laxminarayan A, Lloyd DR. Simple method of extrapolating the coexistence curve and predicting the melting point depression curve from cloud point data for polymer-diluent systems. Polymer. 1994;35(20):4404–7.

Zhang J, Fu J, Wang XL. Effect of diluents on hydrophilic ethylene-acrylic acid co-polymer membrane structure via thermally induced phase separation. Desalination. 2006;192(1–3):151–9.

Cebe P, Hong SD. Crystallization behavior of poly (ether–ether–ketone). Polymer. 1986;27(8):1183–92.

Avrami M. Kinetics of phase change (I): general theory. J Chem Phys. 1939;7(12):1103–12.

Avrami M. Kinetics of phase change (II): transformation-time relations for random distribution of nuclei. J Chem Phys. 1940;8(2):212–24.

Avrami M. Granulation, phase change and microstructure. J Chem Phys. 1941;9(2):177–84.

Jeziorny A. Parameters characterizing the kinetics of the non-isothermal crystallization of poly(ethylene terephthalate) determined by DSC. Polymer. 1978;19(10):1142–4.

Huang JW, Chang CC, Kang CC, Yeh MY. Crystallization kinetics and nucleation parameters of Nylon 6 and poly(ethylene-co-glycidyl methacrylate) blend. Thermochim Acta. 2008;468(1–2):66–74.

Rychly J, Janigova I. Avrami equation and nonisothermal crystallization of polyethylene investigated by DSC. Thermochim Acta. 1993;215:211–8.

Shi XM, Jin J, Chen SJ, Zhang J. Multiple melting and partial miscibility of ethylene-vinyl acetate copolymer/low density polyethylene blends. J Appl Polym Sci. 2009;113(5):2863–71.

Liu MY, Zhao QX, Wang YD, Zhang CG, Mo ZS, Cao SK. Melting behaviors, isothermal and non-isothermal crystallization kinetics of nylon 1212. Polymer. 2003;44(8):2537–45.

Choe CR, Lee KH. Nonisothermal crystallization kinetics of poly(etheretherketone) (PEEK). Polym Eng Sci. 1989;29(12):801–5.

Ozawa T. Kinetics of non-isothermal crystallization. Polymer. 1971;12(3):150–8.

Xu JT, Wang Q, Fan ZQ. Non-isothermal crystallization kinetics of exfoliated and intercalated polyethylenemontmorillonite nanocomposites prepared by in situ polymerization. Eur Polym J. 2005;41(12):3011–7.

Liu TX, Mo ZS, Wang S, Zhang H. Nonisothermal melt and cold crystallization kinetics of poly(aryl ether ether ketone ketone). Polym Eng Sci. 1997;37(3):568–71.

Zhang QX, Zhang ZH, Zhang HF, Mo ZS. Isothermal and nonisothermal crystallization kinetics of nylon-46. J Polym Sci B. 2002;40(16):1784–93.

Kissinger HE. Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand. 1956;57(4):217–21.

Vyazovkin S. Modification of the integral isoconversional method to account for variation in the activation energy. J Comput Chem. 2001;22(2):178–83.

Vyazovkin S, Sbirrazzuoli N. Isoconversional analysis of calorimetric data on nonisothermal crystallization of a polymer melt. J Phys Chem B. 2003;107(3):882–8.

Vyazovkin S, Dranca I. Isoconversional analysis of combined melt and glass crystallization data. Macromol Chem Phys. 2006;207(1):20–5.

Qudah AMA, Al-Raheil IA. Morphology and melting behaviour of poly(ethylene terephthalate) crystallized from the glassy state. Polym Int. 1995;38(4):367–73.

McGuire KS, Laxminarayan A, Lloyd DR. Kinetics of droplet growth in liquid-liquid phase separation of polymer-diluent systems: experimental results. Polymer. 1995;36(26):4951–60.

Shen M, Mehra U, Niinomi M, Koberstein JT, Cooper SL. Morphological, rheo-optical, and dynamic mechanical studies of a semicrystalline block copolymer. J Appl Phys. 1974;45(10):4182–9.

Zhang J, Luo F, Wang XL, Chen JF, Xu ZZ. The effect of kinetic factors on the structure of the hydrophilic ethylene-acrylic acid copolymer microporous membranes prepared via thermally induced phase separation. Acta Polym Sin. 2003;42(2):241–6.

Laxminarayan A, McGuire K, Kim S, Lloyd D. Effect of initial composition, phase separation temperature and polymer crystallization on the formation of microcellular structures via thermally induced phase separation. Polymer. 1994;35(14):3060–8.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, J., Chen, S., Jin, J. et al. Non-isothermal melt crystallization kinetics for ethylene–acrylic acid copolymer in diluents via thermally induced phase separation. J Therm Anal Calorim 101, 243–254 (2010). https://doi.org/10.1007/s10973-009-0619-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0619-x