Abstract

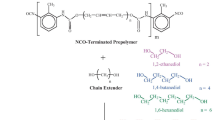

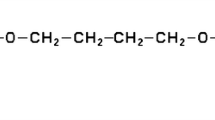

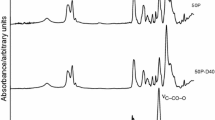

Polyurethanes were prepared from 4,4′-methylenebis (phenyl isocyanate) (MDI), 1,4-butanediol (BD), and poly(tetrahydrofurane) polyether polyol (PTHF) by melt polymerization. The –OH functional group ratio of polyol/total diol was kept constant at 0.4, while the ratio of the isocyanate and hydroxyl groups (NCO/OH) changed between 0.940 and 1.150. The thermal analysis of the polymers by DSC and DMTA measurements indicated several transitions. The three glass transition temperatures observed were assigned to the relaxation of the aliphatic –CH2– groups of the polyol, and to that of the soft and hard segments, respectively. The glass transition temperature of the soft and hard phase changed with the NCO/OH ratio indicating changes in phase structure and composition confirmed also by the maximum in the number of relaxing soft segments. Changes in the relatively small number of end-groups result in considerable modification of mechanical properties. Strength is determined by molecular mass and interactions, while stiffness depends mainly on phase structure. Surprisingly enough, –OH excess yields stiffer polymers, since the interaction of the –OH groups results in a decrease in the amount of the soft phase. A unique correlation was found between tensile modulus and the number of relaxing soft segments.

Similar content being viewed by others

References

Randall D, Lee S, editors. The polyurethanes book. New York: Wiley; 2002.

Bártolo P, Bidanda B. Bio-materials and prototyping applications in medicine. New York: Springer; 2008.

Lamba NMK, Woodhouse KA, Cooper SL. Polyurethanes in biomedical applications. Boca Raton: CRC Press; 1997.

Guelcher SA, Gallagher KM, Didier JE, Klinedinst DB, Doctor JS, Goldstein AS, et al. Synthesis of biocompatible segmented polyurethanes from aliphatic diisocyanates and diurea diol chain extenders. Acta Biomater. 2005;1:471–4.

Wiggins MJ, MacEwan M, nderson JM, Anne H. Effect of soft-segment chemistry on polyurethane biostability during in vitro fatigue loading. J Biomed Mater Res A. 2004;68A:668–83.

Bajsic EG, Rek V, Sendijarevi A, Sendijarevit V, Frish KC. The effect of different molecular weight of soft segments in polyurethanes on photooxidative stability. Polym Degrad Stab. 1996;52:223–33.

Furukawa M, Shiiba T, Murata S. Mechanical properties and hydrolytic stability of polyesterurethane elastomers with alkyl side groups. Polymer. 1999;40:1791–8.

Kim H-D, Lee T-J, Huh J-H, Lee D-J. Preparation and properties of segmented thermoplastic polyurethane elastomers with two different soft segments. J Appl Polym Sci. 1999;73:345–52.

Macosko CW. RIM, fundamentals of reaction injection molding. Munich: Hanser; 1989.

Jasińska L, Haponiuk JT, Balas A. Dynamic mechanical properties and thermal degradation process of the compositions obtained from unsaturated poly(ester urethanes) cross-linked with styrene. J Therm Anal Calorim. 2008;93:777–81.

Lin B, Yang L, Dai H, Hou Q, Zhang L. Thermal analysis of soybean oil based polyols. J Therm Anal Calorim. 2009;95:977–83.

Ayres E, Oréfice RL, Yoshida MI. Phase morphology of hydrolysable polyurethanes derived from aqueous dispersions. Eur Polym J. 2007;43:3510–21.

Miller JA, Speckhard TA, Cooper SL. Monte Carlo simulation study of the polymerization of polyurethane block copolymers. 2. Modeling of premature phase separation during reaction using the two-phase ideal reaction model. Macromolecules. 1986;19:1568–74.

Stanford JL, Still R, Wilkinson A. Effects of soft segment prepolymer functionality on structure development in RIM copolymers. Polymer. 1995;36:3555–64.

Kang W, Stoffer JO. Effect of hard segments on morphology of polyurethanes. Polymer Prepr. 2000;41:1132–3.

Chu B, Gao T, Li Y, Wang J, Desper CR, Byrne CA. Microphase separation kinetics in segmented polyurethanes: effects of soft segment length and structure. Macromolecules. 1992;25:5724–9.

Król P. Synthesis methods, chemical structures and phase structures of linear polyurethanes properties and applications of linear polyurethanes in polyurethane elastomers, copolymers and ionomers. Prog Mater Sci. 2007;52:915–1015.

Zhou Q, Zhang L, Zhang M, Wang B, Wang S. Miscibility, free volume behavior and properties of blends from cellulose acetate and castor oil-based polyurethane. Polymer. 2003;44:1733–9.

Skarja GA, Woodhouse KA. Structure-property relationships of degradable polyurethane elastomers containing an amino acid-based chain extender. J Appl Polym Sci. 2000;75:1522–34.

Pukánszky B Jr, Bagdi K, Tóvölgyi Zs, Varga J, Botz L, Hudak S, et al. Nanophase separation in segmented polyurethane elastomers: effect of specific interactions on structure and properties. Eur Polym J. 2008;44:2431–8.

Sánchez-Adsuar MS, Pastor-Blas MM, Martin-Martinez JM. Properties of polyurethane elastomers with different hard/soft segment ratio. J Adhes. 1998;67:327–45.

Colby RH, Fetters LJ, Graessley WW. The melt viscosity-molecular weight relationship for linear polymers. Macromolecules. 1987;20:2226–37.

Kovacevic V, Lucic S, Cerovecki Z. Influence of filler surface pre-treatment on the mechanical properties of composites. Int J Adhes Adhes. 1997;17:239–45.

Pukanszky B. Influence of interface interaction on the ultimate tensile properties of polymer composites. Composites. 1990;25:255–62.

Kojio K, Nakashima S, Furukawa M. Microphase-separated structure and mechanical properties of norbornane diisocyanate-based polyurethanes. Polymer. 2007;48:997–1004.

Król P, Pilch-Pitera B. Phase structure and thermal stability of crosslinked polyurethane elastomers based on well-defined prepolymers. J Apply Polym Sci. 2007;104:1464–74.

Velankar S, Cooper SL. Microphase separation and rheological properties of polyurethane melts. 1. Effect of block length. Macromolecules. 1998;31:9181–92.

Garrett JT, Xu R, Cho J, Runt J. Phase separation of diamine chain-extended poly(urethane) copolymers: FTIR spectroscopy and phase transitions. Polymer. 2003;44:2711–9.

Chen TK, Chui JY, Shieh TS. Glass transition behaviors of a polyurethane hard segment based on 4,4′-Diisocyanatodiphenylmethane and 1,4-Butanediol and the calculation of microdomain composition. Macromolecules. 1997;30:5068–74.

Frick A, Rochman A. Characterization of TPU-elastomers by thermal analysis (DSC). Polym Test. 2004;23:413–7.

Crawford DM, Bass RG, Haas TW. Strain effects on thermal transitions and mechanical properties of thermoplastic polyurethane elastomers. Thermochim Acta. 1998;323:53–63.

Chen TK, Shieh TS, Chui JY. Studies on the first DSC endotherm of polyurethane hard segment based on 4,4′-Diphenylmethane Diisocyanate and 1,4-Butanediol. Macromolecules. 1998;31:1312–20.

Acknowledgements

We would like to express our sincere gratitude to Stephan Hudak, Tamás Dóczi, Lajos Botz, and Zsuzsa Tóvölgyi for calling our attention to the importance of PU elastomers in medicine and for their initiative in launching this research. The project was partially financed by the National Scientific Research Fund of Hungary (OTKA Grant No. K 68748); its support is highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bagdi, K., Molnár, K., Pukánszky, B. et al. Thermal analysis of the structure of segmented polyurethane elastomers. J Therm Anal Calorim 98, 825–832 (2009). https://doi.org/10.1007/s10973-009-0528-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0528-z