Abstract

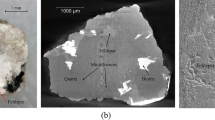

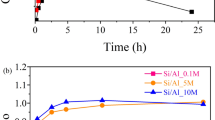

Noncontact dilatometry, compared to differential scanning calorimetry (DSC), was used together with scanning electron microscopy and densification behavior studies to investigate the parameters that govern the kinetics of transformation of kaolin to mullite during sintering. Three kaolinitc clays from Cameroon, with different SiO2/Al2O3 molar ratio, were examined. The temperatures of mullite nucleation were 973, 979, and 984 °C at 5 °C/min heating rate, respectively, for values of SiO2/Al2O3 molar ratio equal to 4.22, 2.22, and 2.08. At 20 °C/min heating rate, the temperatures are shifted to higher values, 992, 997, and 1,001 °C. The mullitization phenomenon, which includes a first step of nucleation and a second one of crystal growth, presented activation energy in the range of 650–730 kJ/mol, depending on the nature of the sample investigated. These values, obtained by noncontact dilatometer measurements, were comparable to those obtained by means of DSC and are in agreement with literature values. The difference in sintering kinetics for the three kaolinitic clays could explain the different morphologies obtained for the mullite grains.

Similar content being viewed by others

References

Kamseu E, Leonelli C, Boccaccini DN. Non-contact dilatometry of hard and soft porcelain compositions. J Therm Anal Calorim. 2007;88(2):571–6.

Kingery WD, Bowen HK, Uhlmann DR. Introduction to ceramics. 2nd ed. New York: Wiley; 1976.

Raether F, Hofmann R, Muller G, Solter HJ. A novel thermo-optical measuring system for the in situ study of sintering processes. J Therm Anal Calorim. 1998;53:717–35.

Paganelli M. Using optical dilatometer to determine sintering behaviour. Am Ceram Soc Bull. 2002;81(11):25–30.

Boccaccini AR, Hamann B. Review in situ high-temperature optical microscopy. J Mater Sci. 1999;34:5419–36.

Karamanov A, Aloisi M, Pelino M. Sintering behaviour of glass obtained from MSWI ash. J Eur Ceram Soc. 2005;25:1531–40.

Romero M, Martín-Márquez J, Rincon JMa. Mullite formation kinetic from a porcelain stoneware body for tiles production. J Eur Ceram Soc. 2006;26(9):1647–52.

Traorè K, Gridi-Bennadji F, Blanchart P. Significance of kinetic theories on the recrystallization of kaolinite. Thermochim Acta. 2006;451:99–104.

Sestak J. Thermophysical properties of solids—their measurements and theoretical thermal analysis. Prague: Academia; 1984.

Chen H. A method for evaluating viscosities of metallic glasses from the rates of thermal transformations. J Non-Cryst Solids. 1978;27:257–63.

Brown E. Handbook of thermal analysis and calorimetry. Amsterdam: Elsevier; 1998.

Kamseu E, Braccini S, Corradi A, Leonelli C. Microstructural evolution during thermal treatment of three kaolinitic clays from Cameroon. Adv Appl Ceram. 2009;108(6):338–46.

Njoya A, NKoumbou C, Grosbois C, Njopwouo D, Njoya D, Courtin-Nomade A, et al. Genesis of Mayouom kaolin deposit (western Cameroon). Appl Clay Sci. 2006;32:125–40.

Paganelli M. Sintering behaviour of clays for the production of ceramics. cfi/Ber. DKG 2007;84(5):E1–3, see also www.expertsystemsolutions.com.

Murray P, White J. Interpretation of the differential thermal analysis of the clay minerals. Part IV: kinetics of the thermal dehydration of clays. Trans Br Ceram Soc. 1955;54:137.

Castelein O, Soulestin B, Bonnet JP, Blanchart P. The influence of heating rate on the thermal behaviour and mullite formation from a kaolin raw material. Ceram Int. 2001;27:517–22.

Schumucker M, Hildmann B, Schneider H. Mechanism of 2/1- to 3/2-mullite transformation at 1650 °C. Am Mineral. 2002;87:1190–3.

Takei T, Kameshima Y, Yasumori A, Okada K. Crystallisation kinetics of mullite in alumina-silica glass fibers. J Am Ceram Soc. 1999;82(10):2980–7.

Paulik F. Transformation-governed heating techniques in thermal analysis I. J Therm Anal Calorim. 1999;58:711–23.

Chen CY, Tuan CS. Microstructural evolution of mullite during the sintering of kaolin powder compacts. Ceram Int. 2000;26:715–20.

Ribeiro MJ, Tulyagavov DU, Ferreira JM, Labrincha JA. High temperature mullite dissolution in ceramic bodies derived from Al-rich sludge. J Eur Ceram Soc. 2005;25:703–10.

Leonelli C, Kamseu E, Melo UC, Corradi A, Pellacani GC. Mullitization behaviour during thermal treatment of three kaolinitic clays from Cameroon: densification, sintering kinetics and microstructure. Interceram. 2008;57(6):396–401.

Lu HY, Wang WL, Tuan WH, Lin MH. Acicular mullite crystals in vitrified kaolin. J Am Ceram Soc. 2004;87(10):1843–7.

Ligero RA, Vazques J, Casas-Ruiz M, Jiménez-Garay R. A study of the crystallization kinetics of some Cu–As–Te glasses. J Mater Sci. 1991;6:211–5.

Zhao H, Hiragushi K, Mizota Y. Mullite formation of colloidal matrix hybrid aluminosilicate gel. J Sol–Gel Sci Technol. 2003;27:287–91.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kamseu, E., Rizzuti, A., Miselli, P. et al. Use of noncontact dilatometry for the assessment of the sintering kinetics during mullitization of three kaolinitic clays from Cameroon. J Therm Anal Calorim 98, 757–763 (2009). https://doi.org/10.1007/s10973-009-0434-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0434-4