Abstract

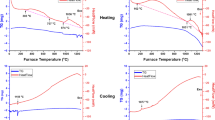

Ironmaking involves reduction of iron ores to metallic iron using coke, coal or gas as reductants. Although different iron ore reduction processes exist, prior to each reduction type, commonly, the hydroxyl and clay materials present in the iron ores undergo decomposition as a first stage. The mass loss during decomposition of these materials is termed as Loss on Ignition (LOI). The aim of this work is to apply a computer aided thermoanalytical technique to evaluate five different iron ore types during decomposition of the LOI matter and determine associated decomposition temperature ranges and heats of reactions. Fourier Transform Infrared (FTIR) spectroscopy and thermogravimetric analysis (TG) were also incorporated to support the analysis interpretation. Three distinctive temperature ranges of decomposition of iron ore LOI matter were detected. The first region was associated with dehydration of the hygroscopic moisture at a temperature range between 100 and 150 °C. The second region occurred at a temperature range between 260 and 425 °C during which strongly bonded water was released and the OH groups associated with primarily iron oxyhydroxides were fractured. The third range, which occurred at a temperature range of 530 and 605 °C, was related to decomposition of the aluminosilicate clay materials.

Similar content being viewed by others

References

Fenton MD. U.S. Geological Survey, Mineral Commodity Summaries, January 2009 http://minerals.usgs.gov/minerals/pubs/commodity/iron_&_steel/mcs-2009-feste.pdf. 2009.

Varajāo CAC, Bruand A, Ramanaidou ER, Gilkes RJ. Microporosity of BIF hosted massive hematite ore, Iron Quadrangle, Brazil. An Acad Bras Ciênc. 2002;74:113–26.

Kim JR, Kang HS, Lee HJ, Je JH, Jeong SK, Tsai W-L, et al. Real-time microradiology of disintegration of iron ore sinteres. Nucl Instrum Methods Phys Res B. 2003;199:441–5.

Weissenborn PK, Dunn JG, Warren LJ. Quantitative thermogravimetric analysis of hematite, goethite and kaolinite in Western-Australian iron-ores. Thermochim Acta. 1994;239:147–56.

Mitov I, Paneva D, Kunev B. Comparative study of the thermal decomposition of iron oxyhydroxides. Thermochim Acta. 2002;386:179–88.

Fan H, Song B, Li Q. Thermal behavior of goethite during transformation to hematite. Mater Chem Phys. 2006;98:148–53.

O’Connor F, Cheung WH, Valix M. Reduction roasting of limonite ores: effect of dehydroxylation International. Int J Miner Process. 2006;80:88–99.

Prasad PSR, Prasad KS, Chaitanya VK, Babu EVSSK, Sreedhar B, Murthy SR. In situ FTIR study on the dehydration of natural goethite. J Asian Earth Sci. 2006;27:503–11.

Walter D. Characterization of synthetic hydrous hematite pigments. Thermochim Acta. 2006;445:195–9.

Dweck J. Qualitative and quantitative characterization of Brazilian natural and organophilic clays by thermal analysis. J Therm Anal Calorim. 2008;92:129–35.

López FA, Ramirez MC, Pons JA, López-Delgado A, Alguacil FJ. Kinetic study of the thermal decomposition of low-grade nickeliferous laterite ores. J Therm Anal Calorim. 2008;94:517–22.

Strezov V, Lucas JA, Strezov L. Computer aided thermal analysis. J Therm Anal Calorim. 2003;72:907–18.

Wolska E. The structure of hydrohematite. Z Kristallogr. 1981;154:69–75.

Cornell RM, Schwertmann U. The iron oxides—Structure, properties, reactions, occurrences and uses. VCH: Weinheim; 2003.

Schulze DG. The influence of aluminum on iron oxides; VII, Unit-cell dimensions of Al-substituted goethites and estimation of Al from them. Clays Clay Min. 1984;32:36–44.

Alvarez M, Rueda EH, Sileo EE. Simultaneous incorporation of Mn and Al in the goethite structure. Geochim Cosmochim Acta. 2007;71:1009–20.

Wells MA, Fitzpatrick RW, Gilkes RJ. Thermal and mineral properties of Al- Cr- Mn- Ni- and Ti-substituted goethite. Clays Clay Min. 2006;54:176–94.

McCann G, Strezov V, Lucas J, Evans T, Strezov L. Iron ore characterisation during high temperature thermal processing. Dev Chem Eng Min Proc. 2004;12:369–82.

Lanza R, Meloni A. The Earth’s magnetism. An introduction for geologists. Springer-Verlag, Berlin; 2006. p. 92.

Ruan HD, Frost RL, Kloprogge JT. The behavior of hydroxyl units of synthetic goethite and its dehydroxylated product hematite. Spectrochim Acta A. 2001;57:2575–86.

Kristóf J, Frost RL, Felinger A, Mink J. FTIR spectroscopic study of intercalated kaolinite. J Mol Struct. 1997;410–411:119–22.

Castaldi P, Silveti M, Santona L, Enzo S, Melis P. Clays Clay Min. 2008;56:461–9.

Acknowledgements

The authors acknowledge financial support from the Australian Research Council and Hamersley Iron (grant no: LP0882722).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Strezov, V., Ziolkowski, A., Evans, T.J. et al. Assessment of evolution of loss on ignition matter during heating of iron ores. J Therm Anal Calorim 100, 901–907 (2010). https://doi.org/10.1007/s10973-009-0398-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0398-4