Abstract

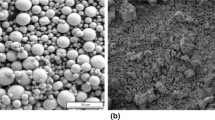

Carbon fiber reinforced polymer matrix (CFRP) composites often require organic coatings for decorative and protective purposes. Due to the smoothness and low polarity, the surface must be polished to make the coating have sufficient adhesion strength. However, sanding process damages the strength of composites and causes dust pollution. In this work, in order to enhance the interfacial adhesion between water-based coating and CFRP composite, SiO2 particles were produced on the composite surface through in-situ heterogeneous deposition by sol-gel method. The effects of this treatment process on the surface morphology, roughness, chemical composition, wettability and coating adhesion strength of CFRP composites were studied, and the adhesion strength was compared with that of traditional sandpaper sanding and acidification process. The results showed that the adhesion strength of the water-based coating increased to 5.72 ± 0.34 MPa on the surface of the CFRP composite panel modified by the heterogeneous deposition of SiO2, when the ammonia content was 0.20 mol L−1, which was 133.47% higher than that of the original sample.

Highlights

-

The deposition of SiO2 particles by sol-gel method can significantly improve the surface energy and surface roughness of CFRP materials.

-

The heterogeneous deposition of SiO2 on the surface of CFRP can effectively enhance the adhesion strength of the coating without causing dust pollution and damage to the composite matrix.

-

The adhesion strength of the water-based coating is increased to 5.72 ± 0.34 MPa on the modified surface of the CFRP composite panel, which was 133.47% higher than that of the original sample.

Similar content being viewed by others

References

Rajak DK, Wagh PH, Linul E (2021) Manufacturing technologies of carbon/glass fiber-reinforced polymer composites and their properties: a review. Polymers 13(21):372

Duchoslav J, Unterweger C, Steinberger R, Fuerst C, Stifter D (2016) Investigation on the thermo-oxidative stability of carbon fiber sizings for application in thermoplastic composites. Polym Degrad Stab 125:33–42

Xiang L, Xiaoyu Z (2019) Application of carbon fiber composite materials in the field of industrial robots. Proc 2019 Int Conf Robot Intell Control Artif Intell. ACM, Shanghai China, p 310–315

Bagherzadeh MR, Mahdavi F, Ghasemi M, Shariatpanahi H, Faridi HR (2010) Using nanoemeraldine salt-polyaniline for preparation of a new anticorrosive water-based epoxy coating. Prog Org Coat 68(4):319–322

Li B, Jiang XF, Wu YP, Wan HQ, Chen L, Ye YP et al. (2019) Novel environmental-friendly lubricating materials: Water-based PAI-graphite-LaF3 bonded solid lubricating coating. Appl Surf Sci 481:900–909

Li B, Jiang XF, Wan HQ, Chen L, Ye YP, Zhou HD et al. (2018) Fabrication and tribological behaviors of a novel environmental friendly water-based PAI-PTFE-LaF 3 bonded solid lubricating composite coating. Tribology Int 121:400–409

Gao Q, Li Y, Wang HE, Liu WP, Shen HL, Zhan XH (2019) Effect of scanning speed with UV laser cleaning on adhesive bonding tensile properties of CFRP. Appl Compos Mater 26(4):1087–1099

Zheng H, Zhang WJ, Li BW, Zhu JJ, Wang CH, Song GJ et al. (2022) Recent advances of interphases in carbon fiber-reinforced polymer composites: a review. Compos Part B: Eng 233:109639

Oliveira V, Sharma SP, de Moura MFSF, Moreira RDF, Vilar R (2017) Surface treatment of CFRP composites using femtosecond laser radiation. Opt Lasers Eng 94:37–43

Li Y, Zhan XH, Gao CY, Wang HE, Yang Y (2019) Comparative study of infrared laser surface treatment and ultraviolet laser surface treatment of CFRP laminates. Int J Adv Manuf Technol 102(9-12):4059–4071

Wang YJ, Yao YS, Xu L, Wu XG, Shen L, Sun GY (2022) Alleviation of honeycomb print-through of NiP/Cu coated carbon fiber composite mirror via robot-arm wheel polishing. Mater Chem Phys 283:126028

Joo SJ, Yu MH, Jeon EB, Kim HS (2017) In situ fabrication of copper electrodes on carbon-fiber-reinforced polymer (CFRP) for damage monitoring by printing and flash light sintering. Compos Sci Technol 142:189–197

Jang J, Yang H (2000) The effect of surface treatment on the performance improvement of carbon fiber/polybenzoxazine composite. J Mater Sci 35(9):2297–2303

Chung HJ, Rhee KY, Lee B, Lee JH (2009) Effect of oxygen plasma treatment on the bonding strength of CFRP/aluminum foam composite. J Alloy Compd 481(1-2):214–219

Rhee KY, Yang JH (2003) A study on the peel and shear strength of aluminum/CFRP composites surface-treated by plasma and ion assisted reaction method. Compos Sci Technol 1(63):33–40

Zou TC, Liu ZH, Li Y, Ju YZ (2022) Effect of plasma surface treatment on bonding properties and surface properties of CFRP. China. Surf Eng 1(35):125–134

Semitekolos D, Kainourgios P, Jones C, Rana A, Koumoulos EP, Charitidis CA (2018) Advanced carbon fibre composites via poly methacrylic acid surface treatment; surface analysis and mechanical properties investigation. Compos Part B-Eng 155:237–243

Fischer F, Kreling S, Jaschke P, Frauenhofer M, Kracht D, Dilger K (2012) Laser surface pre-treatment of CFRP for adhesive bonding in consideration of the absorption behaviour. J Adhes 88(4-6):350–363

Sun CC, Min JY, Lin JP, Wan HL (2019) Effect of atmospheric pressure plasma treatment on adhesive bonding of carbon fiber reinforced polymer. Polymers 11(1):139

Comyn J, Mascia L, Xiao G, Parker BM (1996) Plasma-treatment of polyetheretherketone (PEEK) for adhesive bonding. Int J Adhes Adhes 16(2):97–104

Rossi F, Kylian O, Rauscher H, Hasiwa M, Gilliland D (2009) Low pressure plasma discharges for the sterilization and decontamination of surfaces. N J Phys 11(11):115017

Dhayal M, Alexander MR, Bradley JW (2006) The surface chemistry resulting from low-pressure plasma treatment of polystyrene: the effect of residual vessel bound oxygen. Appl Surf Sci 252(22):7957–7963

Kusano Y (2014) Atmospheric pressure plasma processing for polymer adhesion: a review. J Adhes 90(9):755–777

Kersey L, Ebacher V, Bazargan V, Wang RZ, Stoeber B (2009) The effect of adhesion promoter on the adhesion of PDMS to different substrate materials. Lab a Chip 9(7):1002–1004

Kabir MH, Fawzia S, Chan THT, Gamage JCPH (2016) Comparative durability study of CFRP strengthened tubular steel members under cold weather. Mater Struct 49(5):1761–1774

Ding Y, Yu Z, Zheng J (2017) Rational design of adhesion promoter for organic/inorganic composites. Compos Sci Technol 147:1–7

Tesoro G, Wu YL (1991) Silane coupling agents: the role of the organofunctional group. J Adhes Sci Technol 5(10):771–784

Kutz M (2011) Adhesion promoters: silane coupling agents. PDL Handbook Series 503–517

Ogarev V, Selector S (1992) Organosilicon promotors of adhesion and their influence on the corrosion of metals. Prog Org Coat 21(2-3):135–187

Liu DW, Li G, Li B, Yang XP (2016) Establishment of multi-scale interface in interlayer-toughened CFRP composites by self-assembled PA-MWNTs-EP. Compos Sci Technol 130:53–62

Razavi SMJ, Neisiany RE, Khorasani SN, Ramakrishna S, Berto F (2018) Effect of neat and reinforced polyacrylonitrile nanofibers incorporation on interlaminar fracture toughness of carbon/epoxy composite. Theor Appl Mech Lett 8(2):126–131

Feni F, Jahan M, Dawan F, Ibekwe S, Li GQ, Mensah P (2022) Enhancing the mechanical performance of carbon fiber reinforced polymer using carbonized coconut shell particles. Mater Today Commun 33:104727

Kim K, Jung YC, Kim SY, Yang BJ, Kim J (2018) Adhesion enhancement and damage protection for carbon fiber-reinforced polymer (CFRP) composites via silica particle coating. Compos Part A: Appl Sci Manuf 109:105–114

Li MQ, Zhang L, Li XF, Wang RW, Wu XF, Zhang DH et al. (2023) Improvements of adhesion strength of water-based epoxy resin on carbon fiber reinforced polymer (CFRP) composites via building surface roughness using modified silica particles. Compos Part A Appl Sci Manuf 169:107511

Bogush G, Zukoski C (1991) Studies of the kinetics of the precipitation of uniform silica particles through the hydrolysis and condensation of silicon alkoxides. J Colloid Interface Sci 142(1):1–18

Aelion R, Loebel A, Eirich F (1950) Hydrolysis of ethyl silicate. J Am Chem Soc 72(12):5705–5712

Ip SW, Toguri JM (1994) The equivalency of surface tension, surface energy and surface free energy. J Mater Sci 29(3):688–692

Awaja F, Gilbert M, Kelly G, Fox B, Pigram PJ (2009) Adhesion of polymers. Prog Polym Sci 34(9):948–968

Baier RE, Zisman WA (1975) Wetting properties of collagen and gelatin surfaces. Adv Chem Ser 145:155–174

Brown H (1991) The adhesion between polymers. Annu Rev Mater Sci 21:463–489

Baldan A (2012) Adhesion phenomena in bonded joints. Int J Adhes Adhes 38:95–116

Maeva E, Severina I, Bondarenko S, Chapman G, O’Neill B, Severin F, Maev RG (2004) Acoustical methods for the investigation of adhesively bonded structures: a review. Can J Phys 82(12):981–1025

Zhang GL, Chen J, Meng YH, Wang SH, Long Z (2020) Enhanced wettability and adhesion of carbon fibers with polyimide resin interfaces via grafted modified SiO2 nanoparticles. Compos Interfaces 27(1):125–142

Croll SG (2020) Surface roughness profile and its effect on coating adhesion and corrosion protection: a review. Prog Org Coat 148:105847

Xu Z, Chen L, Huang Y, Li J, Wu XQ, Li XM et al. (2008) Wettability of carbon fibers modified by acrylic acid and interface properties of carbon fiber/epoxy. Eur Polym J 44(2):494–503

Li R, Alizadeh A, Shang W (2010) Adhesion of liquid droplets to rough surfaces. Phys Rev E 82(4):041608

Packham DE (2003) Surface energy, surface topography and adhesion. Int J Adhes Adhes 23(6):437–448

Funding

This work was supported by National Key R&D Program of China (2022YFC3701700) and the Open Research Fund of State Key Laboratory of Multiphase Complex Systems (MPCS-2021-D-11).

Author information

Authors and Affiliations

Contributions

XC: conceptualization, methodology, investigation, software, writing - review & editing. ML: conceptualization, methodology, investigation, software, writing—review & editing. L.Z: validation, conceptualization, supervision, writing—review & editing. AT: investigation, data curation. XL: investigation, data curation. R.W.: data curation, investigation. YC: conceptualization, methodology, writing—review & editing, supervision, funding acquisition. DZ: conceptualization, methodology, writing – review & editing, supervision, funding acquisition. LX: methodology, writing—review & editing, supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Cao, X., Li, M., Zhang, L. et al. Improvements of the interfacial adhesion between water-based coating and carbon fiber reinforced polymer composite by deposition of silica particles. J Sol-Gel Sci Technol 108, 878–888 (2023). https://doi.org/10.1007/s10971-023-06226-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-023-06226-3