Abstract

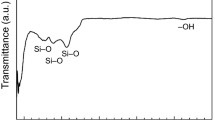

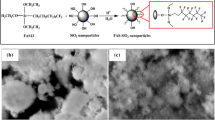

The low cost, accessibility, and ease of implementation of SiO2 hydrophilic coatings should encourage further promotion as practical surface treatments. The calcination process, however, poses an obstacle to convenience. Herein, a calcination-free, antifogging SiO2 superhydrophilic coating was prepared at room temperature by sol–gel method with the guidance of particle gradation theory, which was used to regulate the size and concentration of colloid nanoparticles. The surface micromorphology, roughness, and water contact angle (WCA) of coatings were characterized and measured using scanning electron microscope (SEM), atomic force microscope (AFM), and contact angle measuring equipment. The antifogging capability of superhydrophilic coating was also examined. It has been found that hydrophilicity of coatings can be significantly improved by reasonable particle gradation design. The closer the particle packing pattern is to the hexagonal close-packing model, the better the hydrophilicity of coatings. When the concentration ratio of particle diameter 60.29, 9.26, and 3.68 nm is 15:4:1, the coating exhibits exceptional hydrophilicity (WCA, 2.3°) and outstanding anti-fogging performance. An implication of this study is that a versatile and easily manipulated strategy is presented here for designing surface microstructures that are sensitive to roughness.

Graphical Abstract

Highlights

-

The calcination-free SiO2 superhydrophilic coating was successfully prepared by the sol-gel method.

-

Reasonable matching of colloidal silica particle size can effectively improve the coating hydrophilic performance.

-

The silica coating exhibits exceptional hydrophilicity (WCA, 2.3°) and outstanding anti-fogging performance.

Similar content being viewed by others

References

Otitoju TA, Ahmad AL, Ooi BS (2017) Superhydrophilic (superwetting) surfaces: a review on fabrication and application. J Ind Eng Chem 47:19–40. https://doi.org/10.1016/j.jiec.2016.12.016

Zheng S, Wang D, Tian Y, Jiang L (2016) Superhydrophilic coating induced temporary conductivity for low-cost coating and patterning of insulating surfaces. Adv Funct Mater 26(48):9018–9025. https://doi.org/10.1002/adfm.201602843

Yao L, He J (2014) Recent progress in antireflection and self-cleaning technology—from surface engineering to functional surfaces. Prog Mater Sci 61:94–143. https://doi.org/10.1016/j.pmatsci.2013.12.003

Lu X, Wang Z, Yang X, Xu X, Zhang L, Zhao N, Xu J (2011) Antifogging and antireflective silica film and its application on solar modules. Surf Coat Technol 206(6):1490–1494. https://doi.org/10.1016/j.surfcoat.2011.09.031

Kim K, Dhungel SK, Jung S, Mangalaraj D, Yi J (2008) Texturing of large area multi-crystalline silicon wafers through different chemical approaches for solar cell fabrication. Sol Energy Mater Sol Cells 92(8):960–968. https://doi.org/10.1016/j.solmat.2008.02.036

Lobo AO, Corat MA, Ramos SC, Matsushima JT, Granato AE, Pacheco-Soares C, Corat EJ (2010) Fast preparation of hydroxyapatite/superhydrophilic vertically aligned multiwalled carbon nanotube composites for bioactive application. Langmuir 26(23):18308–18314. https://doi.org/10.1021/la1034646

Weng X, Ji Y, Ma R, Zhao F, An Q, Gao C (2016) Superhydrophilic and antibacterial zwitterionic polyamide nanofiltration membranes for antibiotics separation. J Membr Sci 510:122–130. https://doi.org/10.1016/j.memsci.2016.02.070

Lu T, Xu X, Liu X, Sun T (2017) Super hydrophilic PVDF based composite membrane for efficient separation of tetracycline. Chem Eng J 308:151–159. https://doi.org/10.1016/j.cej.2016.09.009

Liang S, Kang Y, Tiraferri A, Giannelis EP, Huang X, Elimelech M (2013) Highly hydrophilic polyvinylidene fluoride (PVDF) ultrafiltration membranes via postfabrication grafting of surface-tailored silica nanoparticles. ACS Appl Mater Inter 5(14):6694–6703. https://doi.org/10.1021/am401462e

Hancock MJ, Piraino F, Camci-Unal G, Rasponi M, Khademhosseini A (2011) Anisotropic material synthesis by capillary flow in a fluid stripe. Biomaterials 32(27):6493–6504. https://doi.org/10.1016/j.biomaterials.2011.05.057

Wang R, Hashimoto K, Fujishima A, Chikuni M, Kojima E, Kitamura A, Shimohigoshi M, Watanabe T (1997) Light-induced amphiphilic surfaces. Nature 388(6641):431–432. https://doi.org/10.1038/41233

Wang J, Wang D, Wang J, Zhao W, Wang C (2011) High transmittance and superhydrophilicity of porous TiO2/SiO2 bi-layer films without UV irradiation. Surf Coat Technol 205(12):3596–3599. https://doi.org/10.1016/j.surfcoat.2010.12.033

Tricoli A, Righettoni M, Pratsinis SE (2009) Anti-fogging nanofibrous SiO2 and nanostructured SiO2-TiO2 films made by rapid flame deposition and in situ annealing. Langmuir 25(21):12578–12584. https://doi.org/10.1021/la901759p

Wang X, Ding H, Lv G, Zhou R, Ma R, Hou X, Zhang J, Li W (2022) Fabrication of superhydrophilic self-cleaning SiO2–TiO2 coating and its photocatalytic performance. Ceram Int 48(14):20033–20040. https://doi.org/10.1016/j.ceramint.2022.03.278

Li X, He J (2013) Synthesis of raspberry-like SiO2-TiO2 nanoparticles toward antireflective and self-cleaning coatings. ACS Appl Mater Inter 5(11):5282–5290. https://doi.org/10.1021/am401124j

Chen Y, Zhang C, Huang W, Yang C, Huang T, Situ Y, Huang H (2014) Synthesis of porous ZnO/TiO2 thin films with superhydrophilicity and photocatalytic activity via a template-free sol–gel method. Surf Coat Technol 258:531–538. https://doi.org/10.1016/j.surfcoat.2014.08.042

Wu J, Xia J, Lei W, Wang B-p (2011) A one-step method to fabricate lotus leaves-like ZnO film. Mater Lett 65(3):477–479. https://doi.org/10.1016/j.matlet.2010.10.029

Chen H, Li X, Li D (2022) Superhydrophilic–superhydrophobic patterned surfaces: from simplified fabrication to emerging applications. Nanotechnol Precis Eng 5 (3). https://doi.org/10.1063/10.0013222

Ye L, Zhang Y, Song C, Li Y, Jiang B (2017) A simple sol–gel method to prepare superhydrophilic silica coatings. Mater Lett 188:316–318. https://doi.org/10.1016/j.matlet.2016.09.043

Du X, Li X, He J (2010) Facile fabrication of hierarchically structured silica coatings from hierarchically mesoporous silica nanoparticles and their excellent superhydrophilicity and superhydrophobicity. ACS Appl Mater Interfaces 2(8):2365–2372. https://doi.org/10.1021/am1003766

Liu X, He J (2007) Hierarchically structured superhydrophilic coatings fabricated by self-assembling raspberry-like silica nanospheres. J Colloid Interface Sci 314(1):341–345. https://doi.org/10.1016/j.jcis.2007.05.011

Liu X, He J (2009) Superhydrophilic and antireflective properties of silica nanoparticle coatings fabricated via layer-by-layer assembly and postcalcination. J Phys Chem C 113(1):148–152. https://doi.org/10.1021/jp808324c

Li X, He J (2012) In situ assembly of raspberry- and mulberry-like silica nanospheres toward antireflective and antifogging coatings. ACS Appl Mater Inter 4(4):2204–2211. https://doi.org/10.1021/am3002082

Lai Y, Lin C, Wang H, Huang J, Zhuang H, Sun L (2008) Superhydrophilic–superhydrophobic micropattern on TiO2 nanotube films by photocatalytic lithography. Electrochem Commun 10(3):387–391. https://doi.org/10.1016/j.elecom.2007.12.020

Liu H, Feng L, Zhai J, Jiang L, Zhu D (2004) Reversible wettability of a chemical vapor deposition prepared ZnO film between superhydrophobicity and superhydrophilicity. Langmuir 20(14):5659–5661. https://doi.org/10.1021/la036280o

Çağlar A, Cengiz U, Yıldırım M, Kaya İ (2015) Effect of deposition charges on the wettability performance of electrochromic polymers. Appl Surf Sci 331:262–270. https://doi.org/10.1016/j.apsusc.2015.01.103

Godeau G, Darmanin T, Guittard F (2016) Switchable surfaces from highly hydrophobic to highly hydrophilic using covalent imine bonds. J Appl Polym Sci 133 (11). https://doi.org/10.1002/app.43130

Topçu Kaya AS, Cengiz U (2019) Fabrication and application of superhydrophilic antifog surface by sol–gel method. Prog Org Coat 126:75–82. https://doi.org/10.1016/j.porgcoat.2018.10.021

Cebeci FÇ, Wu Z, Zhai L, Cohen RE, Rubner MF (2006) Nanoporosity-driven superhydrophilicity: a means to create multifunctional antifogging coatings. Langmuir 22(6):2856–2862. https://doi.org/10.1021/la053182p

Lin X, Hwangbo S, Jeong H, Cho Y-A, Ahn H-W, Hong J (2016) Organosilicate based superhydrophilic nanofilm with enhanced durability for dentistry application. J Ind Eng Chem 36:30–34. https://doi.org/10.1016/j.jiec.2016.02.017

Moazzam P, Tavassoli H, Razmjou A, Warkiani ME, Asadnia M (2018) Mist harvesting using bioinspired polydopamine coating and microfabrication technology. Desalination 429:111–118. https://doi.org/10.1016/j.desal.2017.12.023

Kim JH, Shim TS, Kim S-H (2016) Lithographic design of overhanging microdisk arrays toward omniphobic surfaces. Adv Mater 28(2):291–298. https://doi.org/10.1002/adma.201503643

Stöber W, Fink A, Bohn E (1968) Controlled growth of monodisperse silica spheres in the micron size range. J Colloid Interface Sci 26(1):62–69. https://doi.org/10.1016/0021-9797(68)90272-5

Acknowledgements

This work was financially supported by the science foundation of the National Key Laboratory Foundation of Science and Technology on Advanced Composites in the Special Environments and Shenzhen Science and Technology Program (Grant No. KQTD2016112814303055).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, M., Sun, Y., Zeng, G. et al. Facile fabrication and antifogging test of a calcination-free SiO2 superhydrophilic coating. J Sol-Gel Sci Technol 105, 662–672 (2023). https://doi.org/10.1007/s10971-023-06042-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-023-06042-9