Abstract

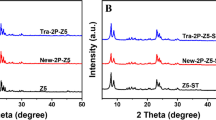

Titanosilicate mesoporous materials (TiSi-MMs) with adjustable textural properties were synthesized by the sol-gel method. Tetraethyl orthosilicate (TEOS) was used as Si source, while tetraethyl orthotitanate (TEOT) or potassium titanium oxide oxalate dihydrate (PTOOD) was used as Ti source. With an increase of Ti content, the specific surface area and pore volume of TiSi-MMs decrease while the pore size increases. The specific surface area, pore volume and average pore diameter of TEOT-derived TiSi-MMs are larger than those of PTOOD-derived TiSi-MMs. In the acetalization reaction of biomass-derived furfural with n-propanol, the conversions of furfural over TEOT-derived TiSi-MMs are higher than that over silicate mesoporous material (Si-MM), demonstrating that the introduction of Ti significantly enhances the catalytic performance. Furthermore, the catalytic performance of TEOT-derived TiSi-MMs is better than that of PTOOD-derived TiSi-MMs. The sample with the largest Ti content and the highest number of strongly acidic sites shows the best catalytic performance. The numbers of strong acidic sites are positively correlated with the Ti contents of TiSi-MMs. Ti content and specific surface area are the two main factors affecting the catalytic performance because they determine the density and intensity of accessible Lewis acidic catalytic sites (coordinatively unsaturated Ti4+) in the catalyst channels, thus determining the catalytic performance in the acetalization reaction. These TiSi-MMs show good catalytic performance and can be used to efficiently catalyze the acetalization reaction of biomass derived furfural and n-propanol.

Graphical abstract

Highlights

-

Lewis acid sites of the catalyst mainly originate from coordinatively unsaturated Ti4+ on surface.

-

The number of strong acidic sites is positively correlated with the Ti content of catalyst.

-

Acid strength rather than acid amount of the catalyst plays a more important role in some cases.

Similar content being viewed by others

References

Zhao Y, Lu K, Xu H, Zhu L, Wang S (2021) A critical review of recent advances in the production of furfural and 5-hydroxymethylfurfural from lignocellulosic biomass through homogeneous catalytic hydrothermal conversion. Renew Sustain Energy Rev 139:110706. https://doi.org/10.1016/j.rser.2021.110706

Yu Z, Lu X, Wang X, Xiong J, Li X, Zhang R, Ji N (2020) Metal-catalyzed hydrogenation of biomass-derived furfural: particle size effects and regulation strategies. ChemSusChem 13:5185–5198. https://doi.org/10.1002/cssc.202001467

Xu C, Paone E, Rodriguez-Padron D, Luque R, Mauriello F (2020) Recent catalytic routes for the preparation and the upgrading of biomass derived furfural and 5-hydroxymethylfurfural. Chem Soc Rev 49:4273–4306. https://doi.org/10.1039/d0cs00041h

Ńivec R, Likozar B, Grilc M (2021) Surface kinetics and transport phenomena modelling for furfural hydrotreatment over Pd/C in isopropanol and tetrahydrofuran. Appl Surf Sci 541:148485. https://doi.org/10.1016/j.apsusc.2020.148485

Nandiwale KY, Vishwakarma M, Rathod S, Simakova I, Bokade VV (2021) One-pot cascade conversion of renewable furfural to levulinic acid over a bifunctional H3PW12O40/SiO2 catalyst in the absence of external H2. Energy Fuels 35:539–545. https://doi.org/10.1021/acs.energyfuels.0c03326

Zhang H, Yang W, Roslan II, Jaenicke S, Chuah G-K (2019) A combo Zr-HY and Al-HY zeolite catalysts for the one-pot cascade transformation of biomass-derived furfural to γ-valerolactone. J Catal 375:56–67. https://doi.org/10.1016/j.jcat.2019.05.020

Kuterasiński Ł, Rojek W, Gackowski M, Zimowska M, Jodłowski PJ (2020) Sonically modified hierarchical FAU-type zeolites as active catalysts for the production of furan from furfural. Ultrason Sonochem 60:104785. https://doi.org/10.1016/j.ultsonch.2019.104785

Gupta NK, Fukuoka A, Nakajima K (2018) Metal-free and selective oxidation of furfural to furoic acid with an n-heterocyclic carbene catalyst. ACS Sustain Chem Eng 6:3434–3442. https://doi.org/10.1021/acssuschemeng.7b03681

Manzoli M, Menegazzo F, Signoretto M, Marchese D (2016) Biomass-derived chemicals: furfural oxidative esterification to Methyl-2-furoate over gold catalysts. Catalysts 6: https://doi.org/10.3390/catal6070107

Dutta S, De S, Saha B, Alam MI (2012) Advances in conversion of hemicellulosic biomass to furfural and upgrading to biofuels. Catal Sci Technol 2:2025–2036. https://doi.org/10.1039/C2CY20235B

da Silva MJ, Teixeira MG (2018) Assessment on the double role of the transition metal salts on the acetalization of furfural: Lewis and Brønsted acid catalysts. Mol Catal 461:40–47. https://doi.org/10.1016/j.mcat.2018.10.002

Du Y, Feng Y, Zou C, Wu X, Huang W (2018) Kinetics and mechanism of acetalisation of furfural to furfural diethyl acetal with Ni-Al layered double hydroxides containing lewis acid sites. Prog React Kinet Mech 43:21–29. https://doi.org/10.3184/146867817x15066861009956

Castellanos-Blanco N, Taborda G, Cobo M (2020) An efficient acetalization method for biomass-derived furfural with ethanol Using γ-Al2O3-supported catalysts. ChemistrySelect 5:3458–3470. https://doi.org/10.1002/slct.202000410

Li X, Yang J, Xu R, Lu L, Kong F, Liang M, Jiang L, Nie S, Si C (2019) Kinetic study of furfural production from Eucalyptus sawdust using H-SAPO-34 as solid Brønsted acid and Lewis acid catalysts in biomass-derived solvents. Ind Crops Products 135:196–205. https://doi.org/10.1016/j.indcrop.2019.04.047

Jeon W, Ban C, Kim JE, Woo HC, Kim DH (2016) Production of furfural from macroalgae-derived alginic acid over Amberlyst-15. J Mol Catal A: Chem 423:264–269. https://doi.org/10.1016/j.molcata.2016.07.020

Kulkarni BS, Krishnamurty S, Pal S (2010) Probing Lewis acidity and reactivity of Sn- and Ti-beta zeolite using industrially important moieties: A periodic density functional study. J Mol Catal A: Chem 329:36–43. https://doi.org/10.1016/j.molcata.2010.06.014

Yu Y, Wang R, Liu W, Chen Z, Liu H, Huang X, Tang Z, Liu Y, He M (2021) Control of Ti active-site microenvironment in titanosilicate catalysts and its effect on oxidation pathways. Appl Catal A: Gen 610:117953. https://doi.org/10.1016/j.apcata.2020.117953

Huo Y, Zhang Y, Xu W, Tang K, Lu X, Ma R, Fu Y, Zhu W (2020) Acid-modulated synthesis of Ti-MWW zeolites with rich framework Ti species for efficient epoxidation. Ind Eng Chem Res 59:19929–19937. https://doi.org/10.1021/acs.iecr.0c03518

Shakeri M, Dehghanpour SB (2020) Rational synthesis of TS-1 zeolite to direct both particle size and framework Ti in favor of enhanced catalytic performance. Microporous Mesoporous Mater 298:110066. https://doi.org/10.1016/j.micromeso.2020.110066

Tang Z, Yu Y, Liu W, Chen Z, Wang R, Liu H, Wu H, Liu Y, He M (2020) Deboronation-assisted construction of defective Ti(OSi)3OH species in MWW-type titanosilicate and their enhanced catalytic performance. Catal Sci Technol 10:2905–2915. https://doi.org/10.1039/D0CY00126K

Su Z, Hu C, Shahzad N, Kim CK (2020) Asymmetric cyanation of activated olefins with ethyl cyanoformate catalyzed by Ti(IV)-catalyst: a theoretical study. Catalysts 10: https://doi.org/10.3390/catal10091079

Stevens WJJ, Lebeau K, Mertens M, Van Tendeloo G, Cool P, Vansant EF (2006) Investigation of the morphology of the mesoporous SBA-16 and SBA-15 Materials. J Phys Chem B 110:9183–9187. https://doi.org/10.1021/jp0548725

Betiha MA, Mahmoud SA, Menoufy MF, Al-Sabagh AM (2011) One-pot template synthesis of Ti-Al-containing mesoporous silicas and their application as potential photocatalytic degradation of chlorophenols. Appl Catal B: Environ 107:316–326. https://doi.org/10.1016/j.apcatb.2011.07.030

Ma Y, Qi L, Ma J, Wu Y, Liu O, Cheng H (2003) Large-pore mesoporous silica spheres: synthesis and application in HPLC. Colloids Surf A: Physicochem Eng Asp 229:1–8. https://doi.org/10.1016/j.colsurfa.2003.08.010

Zhou B, Song F, Ma X, Wang L (2021) Batch and continuous-flow preparation of biomass-derived furfural acetals over a TiO2 nanoparticle-exfoliated montmorillonite composite catalyst. ChemSusChem 14:2341–2351. https://doi.org/10.1002/cssc.202100303

Ingo GM, Dirè S, Babonneau F (1993) XPS studies of SiO2-TiO2 powders prepared by sol-gel process. Appl Surf Sci 70-71:230–234. https://doi.org/10.1016/0169-4332(93)90433-C

Xu Y, Wu S, Wan P, Sun J, Hood ZD (2017) Introducing Ti3+ defects based on lattice distortion for enhanced visible-light photoreactivity in TiO2 microspheres. RSC Adv 7:32461–32467. https://doi.org/10.1039/c7ra04885h

Avasthi S, McClain WE, Man G, Kahn A, Schwartz J, Sturm JC (2013) Hole-blocking titanium-oxide/silicon heterojunction and its application to photovoltaics. Appl Phys Lett 102:203901. https://doi.org/10.1063/1.4803446

Sapkota K, Chaudhary P, Han SS (2018) Environmentally sustainable route to SiO2@Au-Ag nanocomposites for biomedical and catalytic applications. RSC Adv 8:31311–31321. https://doi.org/10.1039/c8ra04502j

Bosman HJM, Kruissink EC, Vanderspoel J, Vandenbrink F (1994) Characterization of the acid strength of SiO2-ZrO2 mixed oxides. J Catal 148:660–672. https://doi.org/10.1006/jcat.1994.1253

Leadbeater NE, Barnard TM, Stencel LM (2008) Batch and continuous-flow preparation of biodiesel derived from butanol and facilitated by microwave heating. Energy & Fuels 22:2005–2008. https://doi.org/10.1021/ef700748

Du Y, Liu X, Wu X, Cheng Q, Ci C, Huang W (2018) Tunable fabrication of NiAl-LDHs containing acid activity sites as green catalyst for acetalization of furfural to furfural diethyl acetal. ChemistrySelect 3:7996–8002. https://doi.org/10.1002/slct.201800302

Zhong Y, Zhou B, Wang L (2020) Fe/FeOx embedded in LDH catalyzing C–C bond-forming reactions of furfural with alcohols in the absence of a homogeneous base. Mol Catal 493: https://doi.org/10.1016/j.mcat.2020.111056

Song H, Jin F, Liu Q, Liu H (2021) Zeolite-catalyzed acetalization reaction of furfural with alcohol under solvent-free conditions. Mol Catal 513: https://doi.org/10.1016/j.mcat.2021.111752

Ma M, Hou P, Zhang P, Cao J, Liu H, Yue H, Tian G, Feng S (2020) Magnetic Fe3O4 nanoparticles as easily separable catalysts for efficient catalytic transfer hydrogenation of biomass-derived furfural to furfuryl alcohol. Appl Catal A-Gen 602: https://doi.org/10.1016/j.apcata.2020.117709

Nagao M, Misu S, Hirayama J, Otomo R, Kamiya Y (2020) Magneli-phase titanium suboxide nanocrystals as highly active catalysts for selective acetalization of furfural. ACS Appl Mater Interfaces 12:2539–2547. https://doi.org/10.1021/acsami.9b19520

Castellanos-Blanco N, Taborda G, Cobo M (2020) An Efficient acetalization method for biomass-derived furfural with ethanol using gamma-Al2O3-supported catalysts. ChemistrySelect 5:3458–3470. https://doi.org/10.1002/slct.202000410

Tarazanov SV, Grigor’eva EV, Titarenko MA, Klimov NA, Ershov MA, Nikul’shin PA (2018) Furfural dipropyl acetal as a new fuel additive: synthesis and properties. Russian J Appl Chem 91:1968–1973. https://doi.org/10.1134/s107042721812008x

Acknowledgements

This work was supported by National Key Research and Development Program of China (Grant no. 2017YFA0204600)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

About this article

Cite this article

Song, F., Yao, X., Wan, C. et al. Titanosilicate mesoporous materials with adjustable textural properties for catalyzing the acetalization reaction of biomass derived furfural and n-propanol. J Sol-Gel Sci Technol 106, 349–359 (2023). https://doi.org/10.1007/s10971-022-05809-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-022-05809-w