Abstract

Vitrified diamond wheel as high grinding power, good corrosion resistance and self-sharpness is a desirable abrasive tool to difficult-to-machine materials. This study developed a fundamental vitrified bond prepared by sol–gel technique based on refractoriness, bending strength and coefficient of thermal expansion (CTE). The orthogonal experiment design and extreme difference analysis were used to optimize the material composition of Al2O3, SiO2, B2O3, and Na2O. The results show that the influence of Al2O3 and Na2O on refractoriness and CTE is more significant than that of other factors. The influence of Al2O3 and SiO2 on bending strength is more significant than that of other factors. Therefore, the optimal formulation of vitrified bond is recommended to being 80% for SiO2, 5% for B2O3, 10% for Na2O, and 5% for Al2O3, which present excellent performance for vitrified diamond wheels prepared by sol-gel. Besides, the conclusions drawn by orthogonal experiment are reconfirmed by vitrified bond prepared by sol-gel with varied components.

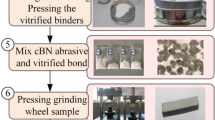

Graphical abstract

Highlights

-

The orthogonal test design and extreme difference analysis were used to optimize the material composition of Al2O3, SiO2, B2O3, and Na2O.

-

The optimal basis formulation of vitrified bond is recommended.

-

Sol–gel is adopted to prepared vitrified bond for precision grinding.

Similar content being viewed by others

References

Liu Q, Tu HC, Wang XS, Li LB, Ruan H, Wang ZY (2015) Hydrated Na2O–B2O3–SiO2 glass prepared by colloid chemistry method. J Sci J Non-Crystalline Solids 425:190–194. https://doi.org/10.1016/j.jnoncrysol.2015.06.019

Li K, Kou HM, Ning CQ (2021) Sintering and mechanical properties of lithium disilicate glass-ceramics prepared by sol-gel method. J Sci J Non-Crystalline Solids 552:120443. https://doi.org/10.1016/j.jnoncrysol.2020.120443

Wang S, Zhao QL, Guo B, Pan YC (2020) Ultra-precision raster grinding of monocrystalline silicon biconical free-form optics using arc-shaped diamond grinding wheels. J Sci J Manuf Process 58:1064–1074. https://doi.org/10.1016/j.jmapro.2020.09.020

Kopac J, Krajnik P (2006) High-performance grinding—a review. J Sci J Mater Process Technol 175:278–284. https://doi.org/10.1016/j.jmatprotec.2005.04.010

Cook MW, Bossom PK (2000) Trends and recent developments in the material manufacture and cutting tool application of polycrystalline diamond and polycrystalline cubic boron nitride. J Sci Int J Refractory Met Hard Mater 18:147–152. https://doi.org/10.1016/S0263-4368(00)00015-9

Wang PF, Li ZH, Zhu YM (2008) Effect of CaO on the surface morphology and strength of water-soaked Na2O–B2O3–Al2O3–SiO2 vitrified bond. J Sci J Non-Crystalline Solid 354:3019–3024. https://doi.org/10.1016/j.jnoncrysol.2007.12.010

Cui L, Hao XJ, Tang Y, Zheng ZH, Yuan YX, Lu AX (2015) Effect of B2O3 on physical properties of LZAS vitrified bond and mechanical properties of diamond composites. J Sci Int J Refractory Met Hard Mater 52:50–54. https://doi.org/10.1016/j.ijrmhm.2015.04.024

Shi J, He F, Xie JL, Liu XQ, Yang H (2019) Effect of heat treatments on the Li2O-Al2O3-SiO2-B2O3-BaO glass-ceramic bond and the glass-ceramic bond cBN grinding tools. J Sci Int J Refractory Met Hard Mater 78:201–209. https://doi.org/10.1016/j.ijrmhm.2018.09.015

Zhang W, Liu XP, Chen SP, Wan L, Li JW, Liao MY (2020) Variations in structure and properties of vitrified bonds and vitrified diamond composites prepared by sol-gel and melting methods at different sintering temperature. J Sci Ceram Int 46:21202–21210. https://doi.org/10.1016/j.ceramint.2020.05.202

Ben-Arfa BasamAE, Neto AnaS, Palama IlariaE, Salvado IsabelMM, Pullar RobertC, Ferreira JoseMF (2019) Robocasting of ceramic glass scaffolds: sol–gel glass, new horizons. J Sci J Eur Ceram Soc 39:1625–1634. https://doi.org/10.1016/j.jeurceramsoc.2018.11.019.

Wang YT, Zhang XT, Xu JB, Shen Y, Wang CA, Li FW, Zhang ZH, Chen J, Ye YH, Shen RQ (2021) Fabrication and characterization of Al–CuO nanocomposites prepared by sol-gel method. J Sci Def Technol 17:1307–1312. https://doi.org/10.1016/j.dt.2020.06.029

Joshi R, Chhibber R (2018) Design and development of SiO2-Al2O3-B2O3-Na2O based glass sealant for the glass-metal joint. J Sci Ceram Int 44:19084–19098. https://doi.org/10.1016/j.ceramint.2018.07.172

Joshi R, Chhibber R (2018) Effect of SiO2/B2O3 ratio on the thermophysical and wetting properties of borosilicate glass sealant for glass-metal joint. J Sci J Mater Process Technol 259:186–194. https://doi.org/10.1016/j.jmatprotec.2018.04.028

Tik A, Sk A, Sahs A, Rka B, De A (2020) Effect of Al2O3 on phase separation and microstructure of R2O-B2O3-Al2O3-SiO2 glass system (R = Li, Na). J Sci J Non-Crystalline Solids 531. https://doi.org/10.1016/j.jnoncrysol.2019.119849

Zheng QJ, Yongman RE, Hogue CL, Mauro JC, Potuzak M, Smedskjaer MM, Yue YZ (2012) Structure of boroaluminosilicate glasses: impact of [Al2O3]/[SiO2] ratio on the structural role of sodium. J Sci Phys Rev B https://doi.org/10.1103/PhysRevB.86.054203

Fernando D, Colon P, Cresswell M, Journet C, Pradelle-Plasse N, Jackson P, Grosgogeat B (2018) The influence of precursor addition order on the porosity of sol-gel bioactive glasses. J Sci Dent Mater 34:1323–1330. https://doi.org/10.1016/j.dental.2018.06.003

Gallyamova R, Dokichev V, Safiullin R, Musin F (2021) The effect of the concentration of water in the silica sol–gel solution on the formation of an oxide film on the surface of carbon fibers. J Sci Mater Today: Proc 38:1584–1587. https://doi.org/10.1016/j.matpr.2020.08.156

Chang SY, Ring TA (1992) Map of gel times for three-phase region tetraethoxysilane, ethanol and water. J Sci J Non-Crystalline Solids 147–148:56–61. https://doi.org/10.1016/S0022-3093(05)80593-9

Zhang S, Peng B, Luo D (2021) Formula optimization of thermosensitive biological sol–gel carrier for EOR surfactants by rheological investigation. J Sci J Pet Sci Eng 205:108740. https://doi.org/10.1016/j.petrol.2021.108740

Prasad AR, Shamsheera KO, Joseph A (2021) Electrochemical and surface characterization of mild steel with corrosion resistant zirconia network fabricated by aqueous sol-gel technique. J Sci J Indian Chem Soc 98:10052. https://doi.org/10.1016/j.jics.2021.100052

Sevim F, Demir F, Bilen M, Hueseyin O (2006) Kinetic analysis of thermal decomposition of boric acid from thermogravimetric data J Sci Korean J Chem Eng 23:736–740. https://doi.org/10.1007/BF02705920

Zhao DP, Wang ZL, Xi YY, Zou Q, Li XH, Wang B, Guo XP, Liang M, Li WC, Wang MZ, Zhen YC (2013) Preparation of silica-coated ultrafine diamond and dispersion in ceramic matrix. J Sci Mater Lett 113:134–137. https://doi.org/10.1016/j.matlet.2013.09.052

Kramer CM, Munir ZA, Volponi JV (1982) Differential scanning calorimetry of sodium and potassium nitrates and nitrites. J Sci Thermochim Acta 55:11–17. https://doi.org/10.1016/0040-6031(82)87002-0

Chen SP, Liu XP, Wan L, Gao PZ, Zhang W, Hou ZQ (2020) Effect of V2O5 addition on the wettability of vitrified bond to diamond abrasive and grinding performance of diamond wheels. J Sci Diamond Relat Mater 102. https://doi.org/10.1016/j.diamond.2019.107672

Sun X, Yu TB, Chen Y, Zhang C, Ma ZL (2020) Effect of cobalt on properties of vitrified bond and vitrified cubic boron nitride composites. J Sci Ceram Int 46:5337–5343. https://doi.org/10.1016/j.ceramint.2019.10.286

Wang XZ, Sun X, Ma ZL, Yu TB, Wang WS (2018) Effects of sintering in a high magnetic field on properties of vitrified bond and vitrified CBN composites. J Sci Ceram Int 44:22301–22307. https://doi.org/10.1016/j.ceramint.2018.08.355

Tik A, Sk A, Sahs A, Rka B, De A (2020) Effect of Al2O3 on phase separation and microstructure of R2O-B2O3-Al2O3-SiO2 glass system (R = Li, Na). J Sci J Non-Crystalline Solids 531:119849. https://doi.org/10.1016/j.jnoncrysol.2019.119849

He F, Zhou Q, Xie JL, Zhang QP (2015) Characterization of low sintering temperature and high strength SiO2-B2O3-CaO vitrified bonds for diamond abrasive tools. J Sci Ceram Int 41:3449–3455. https://doi.org/10.1016/j.ceramint.2014.10.150

Yang XZ, Lu DW, Zhu B, Sun ZD, Li G, Li J, Liu Q, Jiang GB (2021) Phase transformation of silica particles in coal and biomass combustion processes. J Sci Environ Pollut 292:118312. https://doi.org/10.1016/j.envpol.2021.118312

Li H, Hrma P, Vienna JD, Qian MX, Su YL, Smith DE (2003) Effects of Al2O3, B2O3, Na2O, and SiO2 on nepheline formation in borosilicate glasses: chemical and physical correlations. J Sci J Non-Crystalline Solids 331:202–216. https://doi.org/10.1016/j.jnoncrysol.2003.08.082

Kaewjaeng S, Kaewkhao J, Limsuwan P, Maghanemi U (2012) Effect of BaO on optical, physical and radiation shielding properties of SiO2-B2O3-Al2O3-CaO-Na2O glasses system. J Sci Procedia Eng 32:1080–1086. https://doi.org/10.1016/j.proeng.2012.02.058

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kong, S., Liu, Y. & Xu, L. Orthogonal experimental study on vitrified bond prepared by sol–gel and verification. J Sol-Gel Sci Technol 103, 74–86 (2022). https://doi.org/10.1007/s10971-022-05775-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-022-05775-3