Abstract

One of the current issues in the development of devices based on porous thin films synthesized by sol gel is the eventual failure of the structural integrity of these systems due to chemical or mechanical stresses. In order to design and build robust systems, it is necessary to evaluate the role that each material forming the device has over its mechanical performance and chemical stability, considering their individual properties, their spatial arrangement, and the interfaces between them. In this work, the structural and mechanical evaluation of multilayers based on silica and titania mesoporous films is presented, and the variables that affect the structural integrity of these multilayered devices are evaluated. In addition, the chemical and mechanical stability of these optical devices against flow stress is assessed, simulating operating conditions of the sensors in a liquid environment. Single layer, bilayers, and multilayered devices were synthesized using the sol–gel method in combination with surfactant self-assembly, and their mechanical and structural properties were evaluated with electron and optical microscopy, X-ray reflectometry, and instrumented indentation. After these studies, improvements to the materials forming the device are proposed to maximize the structural integrity of the system.

In this work, the structural and mechanical evaluation of multilayers based on silica and titania mesoporous thin films is presented, and the variables that affect the structural integrity of these multilayered devices are evaluated. In addition, the chemical and mechanical stability of these optical devices against flow stress is assessed, simulating operating conditions of the sensors in a liquid environment.

Highlights

-

Silica mesoporous films present a ductile behavior while titania mesoporous films are more brittle.

-

The spatial disposition of SiO2 and TiO2 layers in bilayer structures modifies the failure mode.

-

The mesoporous SiO2–TiO2 multilayer mechanical behavior is modulated by the SiO2 layers.

-

The optical and mechanical behavior of the photonic device changes after immersion in water at 40 °C.

Similar content being viewed by others

References

Innocenzi P, Malfatti L (2013) Mesoporous thin films: properties and applications. Chem Soc Rev 42(9):4198–4216. https://doi.org/10.1039/c3cs35377j

Soler-Illia GJAA, Angelome PC, Fuertes MC, Grosso D, Boissiere C (2012) Critical aspects in the production of periodically ordered mesoporous titania thin films. Nanoscale 4(8):2549–2566. https://doi.org/10.1039/C2NR11817C

Alvarez-Fernandez A, Reid B, Fornerod MJ, Taylor A, Divitini G, Guldin S (2020) Structural characterization of mesoporous thin film architectures: a tutorial overview. ACS Appl Mater Interfaces 12(5):5195–5208. https://doi.org/10.1021/acsami.9b17899

Nicole L, Boissiere C, Grosso D, Quach A, Sanchez C (2005) Mesostructured hybrid organic-inorganic thin films. J Mater Chem 15(35-36):3598–3627. https://doi.org/10.1039/B506072A

Sanchez C, Boissière C, Grosso D, Laberty C, Nicole L (2008) Design, synthesis, and properties of inorganic and hybrid thin films having periodically organized nanoporosity. Chem Mater 20(3):682–737. https://doi.org/10.1021/cm702100t

Bigdeli A, Ghasemi F, Golmohammadi H, Abbasi-Moayed S, Nejad MAF, Fahimi-Kashani N, Jafarinejad S, Shahrajabian M, Hormozi-Nezhad MR (2017) Nanoparticle-based optical sensor arrays. Nanoscale 9(43):16546–16563. https://doi.org/10.1039/C7NR03311G

Homola J (2008) Surface plasmon resonance sensors for detection of chemical and biological species. Chem Rev 108(2):462–493. https://doi.org/10.1021/cr068107d

Inan H, Poyraz M, Inci F, Lifson MA, Baday M, Cunningham BT, Demirci U (2017) Photonic crystals: emerging biosensors and their promise for point-of-care applications. Chem Soc Rev 46(2):366–388. https://doi.org/10.1039/c6cs00206d

Xu H, Wu P, Zhu C, Elbaz A, Gu ZZ (2013) Photonic crystal for gas sensing. J Mater Chem C 1(38):6087–6087. https://doi.org/10.1039/c3tc30722k

Wang F, Meng Z, Xue F, Xue M, Lu W, Chen W, Wang Q, Wang Y (2014) Responsive photonic crystal for the sensing of environmental pollutants. Trends Environ Anal Chem 3:1–6. https://doi.org/10.1016/j.teac.2014.09.002

Burgess IB, Loncar M, Aizenberg J (2013) Structural colour in colourimetric sensors and indicators. J Mater Chem C 1(38):6075–6086. https://doi.org/10.1039/c3tc30919c

Wang H, Zhang K-Q (2013) Photonic crystal structures with tunable structure color as colorimetric sensors. Sensors 13(4):4192. https://doi.org/10.3390/s130404192

Fenzl C, Hirsch T, Wolfbeis OS (2014) Photonic crystals for chemical sensing and biosensing. Angew Chem Int Ed 53(13):3318–3335. https://doi.org/10.1002/anie.201307828

Colodrero S, Ocaña M, González-Elipe AR, Míguez H (2008) Response of nanoparticle-based one-dimensional photonic crystals to ambient vapor pressure. Langmuir 24(16):9135–9139. https://doi.org/10.1021/la801210q

Bonifacio LD, Ozin GA, Arsenault AC (2011) Photonic nose–sensor platform for water and food quality control. Small 7(22):3153–3157. https://doi.org/10.1002/smll.201101074

Bonifacio LD, Puzzo DP, Breslav S, Willey BM, McGeer A, Ozin GA (2010) Towards the photonic nose: a novel platform for molecule and bacteria identification. Adv Mater 22(12):1351–1354. https://doi.org/10.1002/adma.200902763

Colodrero S, Ocaña M, Míguez H (2008) Nanoparticle-based one-dimensional photonic crystals. Langmuir 24(9):4430–4434. https://doi.org/10.1021/la703987r

Ge J, Yin Y (2011) Responsive photonic crystals. Angew Chem Int Ed 50(7):1492–1522. https://doi.org/10.1002/anie.200907091

Sansierra MC, Morrone J, Cornacchiulo F, Fuertes MC, Angelomé PC (2019) Detection of organic vapors using tamm mode based devices built from mesoporous oxide thin films. ChemNanoMat 5(10):1289–1295. https://doi.org/10.1002/cnma.201900388

Fuertes MC, Colodrero S, Lozano G, González-Elipe AR, Grosso D, Boissière C, Sánchez C, Soler-Illia GJAA, Míguez H (2008) Sorption properties of mesoporous multilayer thin films. J Phys Chem C 112(9):3157–3163. https://doi.org/10.1021/jp710612y

Fuertes MC, López-Alcaraz FJ, Marchi MC, Troiani HE, Luca V, Míguez H, Soler-Illia GJAA (2007) Photonic crystals from ordered mesoporous thin-film functional building blocks. Adv Funct Mater 17(8):1247–1254. https://doi.org/10.1002/adfm.200601190

Hidalgo N, Calvo ME, Míguez H (2009) Mesostructured thin films as responsive optical coatings of photonic crystals. Small 5(20):2309–2315. https://doi.org/10.1002/smll.200900411

Hidalgo N, Calvo ME, Bellino MG, Soler-Illia GJAA, Míguez H (2011) Porous supramolecularly templated optical resonators built in 1D photonic crystals. Adv Funct Mater 21(13):2534–2540. https://doi.org/10.1002/adfm.201002486

Choi SY, Mamak M, von Freymann G, Chopra N, Ozin GA (2006) Mesoporous Bragg stack color tunable sensors. Nano Lett 6(11):2456–2461. https://doi.org/10.1021/nl061580m

Ghazzal MN, Deparis O, De Coninck J, Gaigneaux EM (2013) Tailored refractive index of inorganic mesoporous mixed-oxide Bragg stacks with bio-inspired hygrochromic optical properties. J Mater Chem C 1(39):6202–6209. https://doi.org/10.1039/c3tc31178c

Kobler J, Lotsch BV, Ozin GA, Bein T (2009) Vapor-sensitive Bragg mirrors and optical isotherms from mesoporous nanoparticle suspensions. ACS Nano 3(7):1669–1676. https://doi.org/10.1021/nn800911c

Calvo ME, Colodrero S, Hidalgo N, Lozano G, López-López C, Sánchez-Sobrado O, Míguez H (2011) Porous one dimensional photonic crystals: novel multifunctional materials for environmental and energy applications. Energy Environ Sci 4(12):4800–4812. https://doi.org/10.1039/c1ee02081a

Auguié B, Fuertes MC, Angelomé PC, Abdala NL, Soler Illia GJAA, Fainstein A (2014) Tamm plasmon resonance in mesoporous multilayers: toward a sensing application. ACS Photonics 1(9):775–780. https://doi.org/10.1021/ph5001549

Martínez Gazoni R, Bellino MG, Fuertes MC, Gimenez G, Soler-Illia GJAA, Martinez Ricci ML (2017) Designed nanoparticle-mesoporous multilayer nanocomposites as tunable plasmonic-photonic architectures for electromagnetic field enhancement. J Mater Chem C 5(14):3445–3455. https://doi.org/10.1039/C6TC05195B

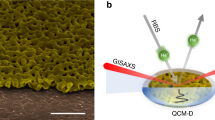

Alberti S, Steinberg PY, Giménez G, Amenitsch H, Ybarra G, Azzaroni O, Angelomé PC, Soler-Illia GJAA (2019) Chemical stability of mesoporous oxide thin film electrodes under electrochemical cycling: from dissolution to stabilization. Langmuir 35(19):6279–6287. https://doi.org/10.1021/acs.langmuir.9b00224

Bindini E, Chehadi Z, Faustini M, Albouy P-A, Grosso D, Cattoni A, Chanéac C, Azzaroni O, Sanchez C, Boissière C (2020) Following in situ the degradation of mesoporous silica in biorelevant conditions: at last, a good comprehension of the structure influence. ACS Appl Mater Interfaces 12(12):13598–13612. https://doi.org/10.1021/acsami.9b19956

Braun K, Pochert A, Beck M, Fiedler R, Gruber J, Lindén M (2016) Dissolution kinetics of mesoporous silica nanoparticles in different simulated body fluids. J Sol-Gel Sci Technol 79(2):319–327. https://doi.org/10.1007/s10971-016-4053-9

Croissant JG, Fatieiev Y, Khashab NM (2017) Degradability and clearance of silicon, organosilica, silsesquioxane, silica mixed oxide, and mesoporous silica nanoparticles. Adv Mater 29(9):1604634. https://doi.org/10.1002/adma.201604634

Dunphy DR, Singer S, Cook AW, Smarsly B, Doshi DA, Brinker CJ (2003) Aqueous stability of mesoporous silica films doped or grafted with aluminum oxide. Langmuir 19(24):10403–10408. https://doi.org/10.1021/la035183s

Fontecave T, Sanchez C, Azaïs T, Boissiére C (2012) Chemical modification as a versatile tool for tuning stability of silica based mesoporous carriers in biologically relevant conditions. Chem Mater 24(22):4326–4336. https://doi.org/10.1021/cm302142k

Möller K, Bein T (2019) Degradable drug carriers: vanishing mesoporous silica nanoparticles. Chem Mater 31(12):4364–4378. https://doi.org/10.1021/acs.chemmater.9b00221

Rimer JD, Trofymluk O, Navrotsky A, Lobo RF, Vlachos DG (2007) Kinetic and thermodynamic studies of silica nanoparticle dissolution. Chem Mater 19(17):4189–4197. https://doi.org/10.1021/cm070708d

Bass JD, Grosso D, Boissiere C, Belamie E, Coradin T, Sanchez C (2007) Stability of mesoporous oxide and mixed metal oxide materials under biologically relevant conditions. Chem Mater 19(17):4349–4356. https://doi.org/10.1021/cm071305g

Steinberg PY, Lionello DF, Medone Acosta DE, Zalduendo MM, Amenitsch H, Granja LP, Marmiroli B, Angelomé PC, Fuertes MC (2021) Structural and mechanical properties of silica mesoporous films synthesized using deep X-rays: implications in the construction of devices. Front Mater 8(27):628245. https://doi.org/10.3389/fmats.2021.628245

Lionello DF, Steinberg PY, Zalduendo MM, Soler-Illia GJAA, Angelomé PC, Fuertes MC (2017) Structural and mechanical evolution of mesoporous films with thermal treatment: the case of Brij 58 templated titania. J Phys Chem C 121(40):22576–22586. https://doi.org/10.1021/acs.jpcc.7b09054

Morrone J, Ramallo JI, Lionello DF, Zelcer A, Auguié B, Angelomé PC, Fuertes MC (2021) Incorporation of porous protective layers as a strategy to improve mechanical stability of Tamm plasmon based detectors. Mater Adv 2(8):2719–2729. https://doi.org/10.1039/D1MA00079A

Brinker CJ, Lu Y, Sellinger A, Fan H(1999) Evaporation-induced self-assembly: nanostructures made easy Adv Mater 11(7):6. https://doi.org/10.1002/(SICI)1521-4095(199905)11:73.0.CO;2-R

Fischer-Cripps AC (2011) Nanoindentation. vol Mechanical Engineering Series, 3rd edn. Springer. https://doi.org/10.1007/978-1-4419-9872-9

Angelomé PC, Fuertes MC, Soler-Illia GJAA (2006) Multifunctional, multilayer, multiscale: integrative synthesis of complex macro and mesoporous thin films with spatial separation of porosity and function. Adv Mater 18:2397–2402. https://doi.org/10.1002/adma.200600439

van der Lee A (2000) Grazing incidence specular reflectivity: theory, experiment, and applications. Solid State Sci 2(2):257–278. https://doi.org/10.1016/S1293-2558(00)00119-9

Steinberg PY, Zalduendo MM, Giménez G, Soler-Illia GJAA, Angelomé PC (2019) TiO2 mesoporous thin film architecture as a tool to control Au nanoparticles growth and sensing capabilities. PCCP 21(20):10347–10356. https://doi.org/10.1039/C9CP01896D

Oliver WC, Pharr GM (2011) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7(6):1564–1583. https://doi.org/10.1557/JMR.1992.1564

Fischer-Cripps AC (2007) Illustrative analysis of load-displacement curves in nanoindentation. J Mater Res 22(11):3075–3086. https://doi.org/10.1557/jmr.2007.0381

Mercier D, Nicolay A, Boudiba A, Vanden Eynde X, Libralesso L, Daniel A, Olivier M (2019) Mechanical properties and decohesion of sol–gel coatings on metallic and glass substrates. J Sol-Gel Sci Technol 93(2):229–243. https://doi.org/10.1007/s10971-019-05196-9

Crepaldi EL, Soler-Illia GJAA, Grosso D, Cagnol F, Ribot F, Sanchez C (2003) Controlled formation of highly organized mesoporous titania thin films: from mesostructured hybrids to mesoporous nanoanatase TiO2. J Am Chem Soc 125(32):9770–9786. https://doi.org/10.1021/ja030070g

Bellino MG, Regazzoni AE, Soler-Illia GJAA (2010) Amylase-functionalized mesoporous silica thin films as robust biocatalyst platforms. ACS Appl Mater Interfaces 2(2):360–365. https://doi.org/10.1021/am900645b

Boissiere C, Grosso D, Lepoutre S, Nicole L, Bruneau AB, Sanchez C (2005) Porosity and mechanical properties of mesoporous thin films assessed by environmental ellipsometric porosimetry. Langmuir 21(26):12362–12371. https://doi.org/10.1021/la050981z

Ha T-J, Park H-H, Jang HW, Yoon S-J, Shin S, Cho HH (2012) Study on the thermal stability of ordered mesoporous SiO2 film for thermal insulating film. Microporous Mesoporous Mater 158:123–128. https://doi.org/10.1016/j.micromeso.2012.03.028

Jauffres D, Yacou C, Verdier M, Dendievel R, Ayral A (2011) Mechanical properties of hierarchical porous silica thin films: Experimental characterization by nanoindentation and Finite Element modeling. Microporous Mesoporous Mater 140:120–129. https://doi.org/10.1016/j.micromeso.2010.09.004

Fan H, Hartshorn C, Buchheit T, Tallant D, Assink R, Simpson R, Kissel DJ, Lacks DJ, Torquato S, Brinker CJ (2007) Modulus-density scaling behaviour and framework architecture of nanoporous self-assembled silicas. Nat Mater 6(6):418–423. https://doi.org/10.1038/nmat1913

Rahman T, Liu R, Ortel E, Kraehnert R, Antoniou A (2014) Mechanical behavior of mesoporous titania thin films. Appl Phys Lett 104(24): https://doi.org/10.1063/1.4883260

Zhou W, Bailey S, Sooryakumar R, King S, Xu G, Mays E, Ege C, Bielefeld J (2011) Elastic properties of porous low-k dielectric nano-films. J Appl Phys 110(4):043520–043520. https://doi.org/10.1063/1.3624583

Flannery CM, Wittkowski T, Jung K, Hillebrands B, Baklanov MR (2002) Critical properties of nanoporous low dielectric constant films revealed by Brillouin light scattering and surface acoustic wave spectroscopy. Appl Phys Lett 80(24):4594–4596. https://doi.org/10.1063/1.1478775

Link A, Sooryakumar R, Bandhu RS, Antonelli GA (2006) Brillouin light scattering studies of the mechanical properties of ultrathin low-k dielectric films. J Appl Phys 100(1): https://doi.org/10.1063/1.2209428

Bailey S, Mays E, Michalak DJ, Chebiam R, King S, Sooryakumar R (2013) Mechanical properties of high porosity low- k dielectric nano-films determined by Brillouin light scattering. J Phys D: Appl Phys 46(4):045308. https://doi.org/10.1088/0022-3727/46/4/045308

Mogilnikov KP, Baklanov MR (2002) Determination of Young’s modulus of porous low-k films by ellipsometric porosimetry. Electrochem Solid-State Lett 5(12):F29–F29. https://doi.org/10.1149/1.1517771

Bai M, Fu X, Dorantes D, Jin B, Hu X (2011) Young’s modulus determination of low-k porous films by wide-band DCC/LD LSAW. J Semicond 32 (10). https://doi.org/10.1088/1674-4926/32/10/103003

Qi H, Xiao X, Kong T (2019) Quantitative simultaneous determination for Young’s modulus and adhesion of low-k thin film by non-destructive CZM-SAW technique. J Nondestruct Eval 38(2):59. https://doi.org/10.1007/s10921-019-0597-2

Xiao X, Shan XM, Kayaba Y, Kohmura K, Tanaka H, Kikkawa T (2011) Young’s modulus evaluation by SAWs for porous silica low-k film with cesium doping. Microelectron Eng 88(5):666–670. https://doi.org/10.1016/j.mee.2010.06.013

Hay J, Crawford B (2011) Measuring substrate-independent modulus of thin films. J Mater Res 26(06):727–738. https://doi.org/10.1557/jmr.2011.8

Mercier D, Fredriksson C (2020) On the design of coating system using nanomechanical experiments. In: Acta Polytechnica CTU Proceedings, 67–72. https://doi.org/10.14311/APP.2020.27.0067

An L, Zhang D, Zhang L, Feng G (2019) Effect of nanoparticle size on the mechanical properties of nanoparticle assemblies. Nanoscale 11(19):9563–9573. https://doi.org/10.1039/C9NR01082C

Kar KK (2017) Composite materials. Processing, applications, characterizations. Springer-Verlag Berlin Heidelberg. https://doi.org/10.1007/978-3-662-49514-8

Balakrishnan G, Sastikumar D, Kuppusami P, Babu RV, Song JI (2018) Microstructural and mechanical properties of Al2O3/ZrO2 nanomultilayer thin films prepared by pulsed laser deposition. Appl Phys A 124(2):158. https://doi.org/10.1007/s00339-018-1576-7

Mammeri F, Bourhis EL, Rozes L, Sanchez C (2005) Mechanical properties of hybrid organic–inorganic materials. J Mater Chem 15(35-36):3787–3811. https://doi.org/10.1039/B507309J

Vanstreels K, Wu C, Verdonck P, Baklanov MR (2012) Intrinsic effect of porosity on mechanical and fracture properties of nanoporous ultralow-k dielectrics. Appl Phys Lett 101(12):123109. https://doi.org/10.1063/1.4753972

Joannopoulos JD, Johnson SG, Winn JN, Meade RD (2011) Photonic crystals: Molding the flow of light. Photonic crystals: molding the flow of light (Second Edition) Princeton University Press, Princeton, United States

Stan G, King SW (2020) Atomic force microscopy for nanoscale mechanical property characterization. J Vac Sci Technol B 38(6). https://doi.org/10.1116/6.0000544

Acknowledgements

JIR and JM acknowledge Consejo Nacional de Ciencia y Técnica (CONICET) for their doctoral scholarships. DFL acknowledges CONICET for a postdoctoral scholarship. M. C. Marchi (CMA-IFIBA-UBA) and S. A. Domínguez (CNEA) are acknowledged for SEM measurements. MCF and PCA are CONICET researchers.

Funding

This work was supported by Agencia Nacional de Promoción de la Investigación, el Desarrollo Tecnológico y la Innovación (PICT 2019-1615, PICT 2017-1133).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Ramallo, J.I., Morrone, J., Lionello, D.F. et al. Mechanical properties and structural integrity of devices based on sol–gel mesoporous oxides thin films. J Sol-Gel Sci Technol 102, 185–196 (2022). https://doi.org/10.1007/s10971-021-05636-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-021-05636-5