Abstract

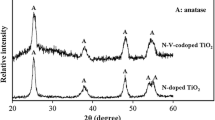

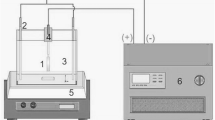

P/Si-TiO2 photocatalytic thick films on FTO glass substrates were prepared. TiO2 thin films, as base layer, were first coated on substrates using a spin-coating technique. The slurry containing P/Si-TiO2 nanoparticles was bar-coated on the surface of TiO2 base layer, followed by calcining at 550 °C. The resultant films were characterized using x-ray diffractometer, scanning electron microscope, UV–Vis spectrophotometer, crosscut adhesion test, and recycling-use test. Under 365-nm UV-light irradiation, abilities of the films to photocatalytically degrade methylene blue were evaluated. The apparent rate laws obeyed 1st-order and the corresponding reaction rate constants (k′), based on the coated area of substrates, were estimated. k′ of the thick film (thickness: 6.5 μm; composition: P/Si-TiO2 anatase crystallites with 16 nm average size) was 49.0 L/(m2-sub. h), which was about eight times of that of the thin film (k′ = 6.2 L/(m2-sub. h); thickness: 215 nm; composition: pure TiO2 anatase crystallites with 8-nm average size).

Highlights

-

P/Si-TiO2 thick films with high photocatalytic activities firmly adhered to FTO glass substrates were prepared using spin-coating, sol-gel and barcoating techniques.

-

The porous thick film (thickness: 6.5 μm) has its reaction rate constant about 8 times of that of the TiO2 thin film (thickness: 215 nm).

-

In kinetic study, the assumption of ignoring the effect of photolysis of dye on concentration changes should be used with cautious considerations, otherwise the photocatalytic activity of the film may be overestimated.

Similar content being viewed by others

References

Hoffmann MR, Martin ST, Choi W, Bahnemann DW (1995) Environmental applications of semiconductor photocatalysis. Chem Rev 95:69–96. https://doi.org/10.1021/cr00033a004

Ohko Y, Hashimoto K, Fujishima A (1997) Kinetics of photocatalytic reactions under extremely low-Intensity UV illumination on titanium dioxide thin films. J Phys Chem A 101:8057–8062. https://doi.org/10.1021/jp972002k

Fujishima A, Rao TN, Tryk DA (2000) Titanium dioxide photocatalysis. J Photochem Photobio C 1:1–21. https://doi.org/10.1016/S1389-5567(00)00002-2

Hashimoto K, Irie H, Fujishima A (2005) TiO2 photocatalysis: a historical overview and future prospects. Jpn J Appl Phys 44:8269–8285. https://doi.org/10.1143/JJAP.44.8269

Anpo M (2001) Preparation, characterization, and reactivities of highly functional titanium oxide-based photocatalysts able to operate under UV–Visible light irradiation: approaches in realizing high efficiency in the use of visible light. Bull Chem Soc Jpn 77:1427–1442. https://doi.org/10.1246/bcsj.77.1427

Chimupala Y, Hyett G, Simpson R, Mitchell R, Douthwaite R, Milne SJ, Brydson RD (2014) Synthesis and characterization of mixed phase anatase TiO2 and sodium-doped TiO2(B) thin films by low pressure chemical vapour deposition (LPCVD). RSC Adv 4:48507–48515. https://doi.org/10.1039/c4ra07570f

Michalcik Z, Horakova M, Spatenka P, Klementova S, Zlamal M, Martin N (2012) Photocatalytic activity of nanostructured titanium dioxide thin films. Int J Photoenergy 689154. https://doi.org/10.1155/2012/689154

Lin H-J, Yang T-S, Hsi C-S, Wang M-C, Lee K-C (2014) Optical and photocatalytic properties of Fe3+-doped TiO2 thin films prepared by a sol-gel spin coating. Ceram Int 40:10633–10640. https://doi.org/10.1016/j.ceramint.2014.03.046

Wu C-Y, Lee YL, Lo Y-S, Lin C-J, Wu C-H (2013) Thickness-dependent photocatalytic performance of nanocrystalline TiO2 thin films prepared by sol-gel spin coating. Appl Surf Sci 280:737–744. https://doi.org/10.1016/j.apsusc.2013.05.053

Yu H-F, Chen L-H (2011) P/Si-TiO2 transparent films with high anatase stability and photocatalytic activity. J Phys Chem Solids 72:269–275. https://doi.org/10.1016/j.jpcs.2011.01.003

Yu H-F, Wang C-W (2011) Photocatalysis and characterization of the gel-derived TiO2 and P–TiO2 transparent thin films. Thin Solid Films 519:6453–6458. https://doi.org/10.1016/j.tsf.2011.04.230

Chang C-C, Chen J-Y, Hsu T-L, Lin C-K, Chan C-C (2008) Photocatalytic properties of porous TiO2/Ag thin films. Thin Solid Films 516:1743–1747. https://doi.org/10.1016/j.tsf.2007.05.033

Sreethawong T, Ngamsinlapasathian S, Yoshikawa S (2014) Positive role of incorporating P-25 TiO2 to mesoporous-assembled TiO2 thin films for improving photocatalytic dye degradation efficiency. J Colloid Interface Sci 430:184–192. https://doi.org/10.1016/j.jcis.2014.05.032

Yu RS, Qin XB, Wang QZ, Zhang P, Wang BY, Wei L, Hao WC, Wang TM (2010) Positron annihilation study of structural effect on photocatalytic activity of mesoporous TiO2 thin films. Nucl Instum Methods Phys Res B 268:2362–2365. https://doi.org/10.1016/j.nimb.2010.04.007

Liu Z, Ya J, E L, Xin Y, Zhao W (2010) Effect of V doping on the band-gap reduction of porous TiO2 films prepared by sol-gel route. Mater Chem Phys 120:277–281. https://doi.org/10.1016/j.matchemphys.2009.11.008

Liu Z, Jin Z, Liu X, Fu Y, Liu G (2006) Fabrication of ordered TiO2 porous thin films by sol-dipping PS template method. J Sol-Gel Sci Technol 38:73–78. https://doi.org/10.1007/s10971-006-5035-0

Zhang W, Chen Y, Yu S, Chen S, Yin Y (2008) Preparation and antibacterial behavior of Fe3+-doped nanostructured TiO2 thin films. Thin Solid Films 516:4690–4694. https://doi.org/10.1016/j.tsf.2007.08.053

Miyauchi M, Tokudome H (2007) Super-hydrophilic and transparent thin films of TiO2 nanotube arrays by a hydrothermal reaction. J Mater Chem 17:2095–2100. https://doi.org/10.1039/b700387k

Xu Y, Shen M (2008) Fabrication of anatase-type TiO2 films by reactive pulsed laser deposition for photocatalyst application. J Mater Process Technol 202:301–306. https://doi.org/10.1016/j.jmatprotec.2007.09.015

Syarif DG, Miyashita A, Yamaki T, Sumita T, Choi Y, Itoh H (2002) Preparation of anatase and rutile thin films by controlling oxygen partial pressure. Appl Surf Sci 193:287–292. https://doi.org/10.1016/S0169-4332(02)00532-9

Samsudin EM, Abd Hamida SB, Juan JC, Basirun WJ, Kandjani AE, Bhargava SK (2016) Effective role of trifluoroacetic acid (TFA) to enhance the photocatalytic activity of F-doped TiO2 prepared by modified sol-gel method. Appl Surf Sci 365:57–68. https://doi.org/10.1016/j.apsusc.2016.01.016

Lei J, Du K, Wei R, zhang S, Ni J, Li W (2014) Assembly of binary templates for fabricating arrayed pores of TiO2 films with hierarchical structures. Mater Lett 133:163–167. https://doi.org/10.1016/j.matlet.2014.06.175

Yu H-F, Yang S-T (2010) Enhancing thermal stability and photocatalytic activity of anatase-TiO2 nanoparticles by co-doping P and Si elements. J Alloy Compd 492:695–700. https://doi.org/10.1016/j.jallcom.2009.12.021

Yu H-F (2007) Photocatalytic abilities of gel-derived P-doped TiO2. J Phys Chem Solids 68:600–607. https://doi.org/10.1016/j.jpcs.2007.01.050

Yu H-F (2007) Phase development and photocatalytic ability of gel-derived P-doped TiO2. J Mater Res 22:2565–2572. https://doi.org/10.1557/JMR.2007.0316

Yu H-F, Hu F-H (2009) Preparation and characterization of transparent TiO2 thin films coated on fused-silica substrates. J Sol-Gel Sci Technol 52:158–165. https://doi.org/10.1007/s10971-009-2005-3

Ahmad I, Usman M, Zhao T, Qayum S, Mahmood I, Mahmood A, Diallo A, Obayi C, Ezema FI, Maaza M (2020) Bandgap engineering of TiO2 nanoparticles through MeV Cu ions irradiation. Arab J Chem 13:3344–3350. https://doi.org/10.1016/j.arabjc.2018.11.008

Sun Z, Pichugin VF, Evdokimov KE, Konishchev ME, Syrtanov MS, Kudiiarov VN, Li K, Tverdokhlebov SI (2020) Effect of nitrogen-doping and post annealing on wettability and band gap energy of TiO2 thin film. Appl Surf Sci 500:144048. https://doi.org/10.1016/j.apsusc.2019.144048

Makuła P, Pacia M, Macyk W (2018) How to correctly determine the band gap energy of modified semiconductor photocatalysts based on UV−Vis spectra. J Phys Chem Lett 9:6814–6817. https://doi.org/10.1021/acs.jpclett.8b02892

Abdullahi SS, Güner S, Koseoglu Y, Musa IM, Adamu BI, Abdulhamid MI (2016) Sımple method for the determınatıon of band gap of a nanopowdered sample usıng Kubelka Munk theory. J Niger Assoc Math Phys 35:241–246

Dastan D (2015) Nanostructured anatase titania thin films prepared by sol-gel dip coating technique. J At Mol Condens Nano Phys 2:109–114

Nair PB, Justinvictor VB, Daniel GP, Joy K, James Raju KC, Kumar DD, Thomas PV (2014) Optical parameters induced by phase transformation in RF magnetron sputtered TiO2 nanostructured thin films. Prog Nat Sci: Mater Int 24:218–225. https://doi.org/10.1016/j.pnsc.2014.05.010

Lin H, Huang CP, Li W, Ni C, Ismat Shah S, Tseng Y-H (2006) Size dependency of nanocrystalline TiO2 on its optical property and photocatalytic reactivity exemplified by 2-chlorophenol. Appl Catal B 68:1–11. https://doi.org/10.1016/j.apcatb.2006.07.018

Gao Y, Masuda Y, Peng Z, Yonezawa T, Koumoto K (2003) Room temperature deposition of a TiO2 thin film from aqueous peroxotitanate solution. J Mater Chem 13:608–613. https://doi.org/10.1039/b208681f

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, HF., Cheng, CW. Enhancing photocatalytic ability of TiO2 films using gel-derived P/Si-TiO2 powder. J Sol-Gel Sci Technol 97, 259–270 (2021). https://doi.org/10.1007/s10971-020-05450-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05450-5