Abstract

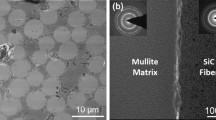

In this study, Al2O3 fiber-reinforced silica matrix composites were fabricated by traditional sol–gel process. To study the mechanical properties of Al2O3/SiO2 composites under high-temperature environment and after high-temperature treatment, the tensile strength and fracture behavior of it under high temperatures were investigated, and their flexural strength after heat treatment at various temperatures was also examined. Our results indicated that the tensile strength of original composites was 85.6 MPa, and that at 1000, 1100, 1200, and 1300 °C was 77.5, 62.5, 52.5, and 40.2 MPa, respectively. The flexural strength of original composites was 78.1 MPa, and that after heat treatment at 1100, 1300, and 1500 °C was 45.5, 40.5, and 27.9 MPa, respectively. The composites exhibited ductile fracture after tensile tests, and still maintain high tensile strength of about 50% even at 1300 °C. What is more, the composites exhibited brittle fracture after heat treatment, with no formation of new phase after heat treatment. In conclusion, our findings suggested that Al2O3/SiO2 composites display outstanding high-temperature properties.

Highlights

-

The continuous alumina fibers reinforced SiO2 matrix (Al2O3/SiO2) composites were prepared.

-

The tensile strength and fracture behavior of Al2O3/SiO2 composites under high temperatures were investigated in detail.

-

The flexural strength after heat treatment at various temperatures of Al2O3/SiO2 composites was also examined.

Similar content being viewed by others

References

Savino R, Criscuolo L, Martino GDD, Mungiguerra S (2018) Aero-thermo-chemical characterization of ultra-high-temperature ceramics for aerospace applications. J Eur Ceram Soc 38:2937–2953. https://doi.org/10.1016/j.jeurceramsoc.2017.12.043

Li S, Feng Z, Liu Y et al. (2010) Microstructural evolution of coating-modified 3D C/SiC composites after annealing in wet oxygen at different temperatures. Corros Sci 52:2873–2845. https://doi.org/10.1016/j.corsci.2010.04.032

Singha P, Pungotrab H et al. (2017) On the characteristics of titanium alloys for the aircraft applications. Mater Today: Proc 4:8971–8982. https://doi.org/10.1016/j.matpr.2017.07.249

Acrobello Variese F, Tului M, Sabbadini S et al. (2013) Optimized coating procedure for the protection of TiAl intermetallic alloy against high temperature oxidation. Intermetallics 37:76–82. https://doi.org/10.1016/j.intermet.2013.02.001

Yang X, Qin W, ZhiHang P, Feng C (2016) High-temperature properties of 2.5D SiO2f/SiO2 composites by sol–gel. Ceram Int 42:12802–12806. https://doi.org/10.1016/j.ceramint.2016.05.043

Li M, Zhou X, Yang H et al. (2016) The effect of the PyC interphase coating on the microwave heating sintered SiC/SiC composites. J Alloy Compd 688:974–981. https://doi.org/10.1016/j.jallcom.2016.07.288

Tonga Y, Zhua W, Baib S, Hua Y, Xiea X, Li Y (2018) Thermal shock resistance of continuous carbon fiber reinforced ZrC based ultra-high temperature ceramic composites prepared via Zr-Si alloyed melt infiltration. Mater Sci Eng: A 735:166–172. https://doi.org/10.1016/j.msea.2018.08.036

Yang X, Qing W, Zhi-hang P, Feng C (2016) High-temperature properties of 2.5D SiO2f/SiO2 composites by sol–gel. Ceram Int 42:12802–12806. https://doi.org/10.1016/j.ceramint.2016.05.043

Xu ZR, Chawla KK, Li X (1993) Effect of high temperature exposure on the tensile strength of alumina fiber Nextel 610. Mater Sci Eng: A 177:249–256. https://doi.org/10.1016/0921-5093(93)90412-8

Zhang H, Zhang Y et al. (2015) Preparation and characterization of continuous alumina based fiber reinforced with orientated mullite whisker. Chem Eng J 268:109–115. https://doi.org/10.1016/j.cej.2014.12.101

Zou CR, Bin L, Meng XJ et al. (2018) Ablation behavior and mechanism of SiO2f/SiO2, SiO2f/BN and Si3N4f/BN radar wave transparent composites. Corros Sci 139:243–254. https://doi.org/10.1016/j.corsci.2018.05.006

Zhang J, Fan JP, Zhang JY et al. (2018) Developing and preparing interfacial coatings for high tensile strength silicon nitride fiber reinforced silica matrix composites. Ceram Int 44:5297–5303. https://doi.org/10.1016/j.ceramint.2017.12.143

Gao TQ, Zhao Y, Zhou GH et al. (2015) Fabrication and characterization of three dimensional woven carbon fiber/silica ceramic matrix composites. Compos Part B: Eng 77:122–128. https://doi.org/10.1016/j.compositesb.2015.02.024

Moser B, Rossoll A, Weber L et al. (2001) Nextel™ 610 alumina fibre reinforced aluminium: influence of matrix and process on flow stress. Compos Part A: Appl Sci Manuf 32:1067–1075. https://doi.org/10.1016/S1359-835X(00)00178-0

Xiao H, Wu JM, Chen AN et al. (2017) Alumina fiber-reinforced silica matrix composites with improved mechanical properties prepared by a novel DCC-HVCI method. Ceram Int 43:12802–12806. https://doi.org/10.1016/j.ceramint.2017.09.023

Chawla KK (2008) Interface engineering in mullite fiber/mullite matrix composites. J Eur Ceram Soc 28:447–453. https://doi.org/10.1016/j.jeurceramsoc.2007.03.008

Wang Y, Liu HT et al. (2015) Interface engineering of fiber-reinforced all-oxide composites fabricated by the sol–gel method with fugitive pyrolytic carbon coatings. Compos Part B: Eng 75:86–94. https://doi.org/10.1016/j.compositesb.2015.01.018

Xiang Y, Wang Q, Cao F, Ma YW, Quan D-l (2017) Sol-gel process and high-temperature property of SiO2/ZrO2-SiO2 composites. Ceram Int 43:854–859. https://doi.org/10.1016/j.ceramint.2016.10.020

Esmaeili AR, Mir N et al. (2020) A facile, fast, and low-cost method for fabrication of micro/nano-textured superhydrophobic surfaces. J Colloid Int Sci 573:317–327. https://doi.org/10.1016/j.jcis.2020.04.027

Liu H, Yang Z, Yuan HA. (2020) Novel elastoplastic constitutive model for woven oxide/oxide ceramic matrix composites with aniso tropic hardening. Compos Struct 229. https://doi.org/10.1016/j.compstruct.2019.111420

Ben Ramdane C, Julian-Jankowiak A, Valle R et al. (2017) Microstructure and mechanical behaviour of a Nextel™ 610/alumina weak matrix composite subjected to tensile and compressive loadings J Eur Ceram Soc 37:2919–2932. https://doi.org/10.1016/j.jeurceramsoc.2017.02.042

Yang Z, Liu H (2020) Effects of thermal aging on the cyclic thermal shock behavior of oxide/oxide ceramic matrix composites. Mater Sci Eng: A 769. https://doi.org/10.1016/j.msea.2019.138494

Schmücker M, Flucht F et al. (2012) Degradation of oxide fibers by thermal overload and environmental effects. Mater Sci Eng: A 557:10–16. https://doi.org/10.1016/j.msea.2012.05.107

Yang LW, Wang JY et al. (2017) Sol-gel temperature dependent ductile-to-brittle transition of aluminosilicate fiber reinforced silica matrix composite. Compos Part B: Eng 119:79–89. https://doi.org/10.1016/j.compositesb.2017.03.043

Acknowledgements

The authors are grateful to Hunan Natural Science Foundation (2020JJ5660) and Key Laboratory Fund (6142907180402) for financial support. The authors are also grateful to Aid Program for Innovative Group of National University of Defense Technology and Aid Program for Science and Technology Innovative Research Team in Higher Educational Institutions of Hunan Province.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, c., Zheng, Z., Cao, F. et al. High-temperature properties of Al2O3/SiO2 composites. J Sol-Gel Sci Technol 97, 63–70 (2021). https://doi.org/10.1007/s10971-020-05413-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05413-w