Abstract

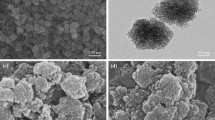

Recently, sol–gel techniques for synthesize inorganic shape-stabilized phase change materials (SS-PCMs) were proposed to successfully improve thermal properties and to accomplish real applications for latent thermal energy storage (TES). In this work, the use of sol–gel process was deeply investigated to develop inorganic SS-PCM, using tetraethyl orthosilicate (TEOS) as monomer and Na2SO4.10H2O as phase change material (PCM). In addition, the influence of pH (acid and basic hydrolysis) and PCM content in the physic and thermal properties of achieved materials were analyzed. Stabilized materials were characterized by infrared spectroscopy, X-ray diffraction, scanning electronic microscopy, scanning differential calorimetry, and thermogravimetry. The characterization results established that direct sol–gel method via acid hydrolysis showed potential to develop inorganic SS-PCMs. However, results indicate that the Na2SO4.10H2O loses water molecules during synthesis, resulting in the anhydrous compound Na2SO4-SiO2; therefore, materials were proposed for high temperature TES applications. Melting point of 880–886 °C and enthalpy of fusion of 23–100 kJ kg−1 were obtained for materials with 20–60 wt.% of PCM content. The new obtained SS-PCMs have enhanced thermal properties, compared with anhydrous Na2SO4: latent storage range RL among 0.1–3.0 °C and thermal cycle stability, for high TES. In addition, direct sol–gel technique was compared with vacuum impregnation method, employing SiO2 as support material. Impregnation procedures were not successfully achieved in this work to stabilize the PCM, which prove the superior significance of direct sol–gel method.

Highlights

-

New inorganic SS-PCM based on Na2SO4 and SiO2 with sol–gel method.

-

Influence of pH and amount of PCM for direct sol–gel synthesis.

-

Direct sol gel method was compared with vacuum impregnation.

-

SiO2 materials (–SiOH and –SiOR) as support materials for vacuum impregnation.

-

Direct sol gel method, via acid hydrolysis show best results.

Similar content being viewed by others

Abbreviations

- TES:

-

Thermal energy storage

- TEOS:

-

Tetraethyl orthosilicate

- PCM:

-

Phase change material

- SS-PCMs:

-

Shape-stabilized phase change materials

- CSE:

-

Core-shell encapsulation

- SEM:

-

Scanning electron microscopy

- EDS:

-

Energy dispersion spectroscopy

- XRD:

-

X-Ray diffraction

- FT-IR:

-

Fourier transform infrared spectroscopy

- DSC:

-

Differential scanning calorimetry

- TG:

-

Thermogravimetry

- SG:

-

Sol–gel method

- RL :

-

Latent storage range

- T(onset, melting):

-

Onset melting temperature

- T(endset, solidification):

-

Endset solidification temperature

- c-PCMcalc:

-

Calculated PCM content (wt.%)

- c-PCMexp:

-

Experimental PCM content (wt.%)

- Tm:

-

Melting point (°C)

- Ts:

-

Solidification point (°C)

- ΔHm :

-

Enthalpy of fusion (kJ kg−1)

- ΔHs :

-

Enthalpy of solidification (kJ kg−1)

- % ΔH:

-

Reduction of the enthalpy of fusion in the SS-PCMs

- ∆Hm_PCM:

-

Enthalpy of fusion of the PCM

- ∆Hm_SS-PCM:

-

Enthalpy of fusion of the SS-PCM

- A.N.:

-

Atomic number

- Normal/Atomic C.:

-

Normal/atomic concentration (wt./at.%)

References

Jamekhorshid A, Sadrameli SM, Farid M (2014) A review of microencapsulation methods of phase change materials (PCMs) as a thermal energy storage (TES) medium. Renew Sustain Energy Rev 31:531–542

Mishra A, Shukla A, Sharma A (2015) Latent heat storage through phase change materials. Resonance 20(6):532–541

Farid MM, Khudhair AM, Ali S, Razack K (2003) A review on phase change energy storage: materials and applications Energy Convers Manag 45(9–10):1597–1615

Sharma RK, Ganesan P, Tyagi V, Metselaar HSC, Sandaran SC (2015) Developments in organic solid–liquid phase change materials and their applications in thermal energy storage. Energy Convers Manag 95:193–228

Liu M, Saman W, Bruno F (2012) Review on storage materials and thermal performance enhancement techniques for high temperature phase change thermal storage systems. Renew Sustain Energy Rev 16:2118–2132

Chen C, Wang L, Huang Y (2008) Morphology and thermal properties of electrospun fatty acids/polyethylene terephthalate composite fibers as novel form-stable phase change materials. Sol Energ Mat Sol Cell 92:1382–1387

Liu H, Awbi HB (2009) Performance of phase change material boards under natural convection. Build Environ 44:1788–1793

Milián YE, Gutiérrez A, Grágeda M, Ushak S (2017) A review on encapsulation techniques for inorganic phase change materials and the influence on their thermophysical properties. Renew Sustain Energy Rev 73:983–999

Safari A, Saidur R, Sulaiman FA, Xu Y, Dong J (2017) A review on supercooling of phase change materials in thermal energy storage systems. Renew Sustain Energy Rev 70:905–919

Su W, Darkwa J, Kokogiannakis G (2015) Review of solid—liquid phase change materials and their encapsulation technologies. Renew Sustain Energy Rev 48:373–391

Wu X, Fan M, Shen X, Tan G (2018). A core-shell structured PCM with Na2SO4 encapsulated by SiO2 for high temperature thermal storage. In ASTFE Digital Library. Begel House Inc.

Giro-paloma J, Martínez M, Cabeza LF, Fernández AI (2016) Types, methods, techniques, and applications for microencapsulated phase change materials (MPCM): A review. Renew Sustain Energy Rev 53:1059–1075

Huang X, Chen X, Li A, Atinafu D, Gao H, Dong W et al. (2019) Shape-stabilized phase change materials based on porous supports for thermal energy storage applications. Chem Eng J 356:641–661

Shah KW (2018) PT US CR. Energy Build. https://doi.org/10.1016/j.enbuild.2018.06.043.

Li M, Shi J (2019) Review on micropore grade inorganic porous medium based form stable composite phase change materials: preparation, performance improvement and effects on the properties of cement mortar. Constr Build Mater 194:287–310

Zhang J, Wang SS, Zhang SD, Tao QH, Pan L, Wang ZY et al. (2011) In situ synthesis and phase change properties of Na2SO4•10H2O@SiO2 solid nanobowls toward smart heat storage. J Phys Chem C 115:20061–20066

Wu Y, Wang T (2014) Thermochimica acta preparation and characterization of hydrated salts/silica composite as shape-stabilized phase change material via sol–gel process. Thermochim Acta 591:10–15

Guo Q, Wang T (2015) Thermochimica acta study on preparation and thermal properties of sodium nitrate/silica composite as shape-stabilized phase change material. Sens Actuators B Chem 613:66–70

Schoth A, Landfester K, Mun R (2015) Surfactant-free polyurethane nanocapsules via inverse Pickering miniemulsion. Langmuir 31(13):3784–3788

Jiang Y, Sun Y, Jacob RD, Bruno F, Li S (2018) Solar energy materials and solar cells novel Na2SO4-NaCl-ceramic composites as high temperature phase change materials for solar thermal power plants (Part I). Sol Energ Mat Sol Cell 178:74–83

Jiang Y, Sun Y, Li S (2019) Solar energy materials and solar cells performance of novel Na2SO4-NaCl-ceramic composites as high temperature phase change materials for solar power plants (Part II). Sol Energ Mat Sol Cell 194:285–294

Xie N, Luo J, Li Z, Huang Z, Gao X, Fang Y (2019) Solar energy materials and solar cells salt hydrate/expanded vermiculite composite as a form-stable phase change material for building energy storage. Sol Energ Mat Sol Cell 189:33–42

Liu L, Peng B, Yue C, Guo M, Zhang M (2019) Low-cost, shape-stabilized fly ash composite phase change material synthesized by using a facile process for building energy efficiency. Mater Chem Phys 222:87–95

Serrano A, del Campo JM, Peco N, Rodriguez JF, Carmona M (2019) Influence of gelation step for preparing PEG–SiO2 shape-stabilized phase change materials by sol–gel method. J Sol–Gel Sci Techn 89(3):731–742

Wang CL, Yeh KL, Chen CW, Lee Y, Lee HL, Lee T (2017) A quick-fix design of phase change material by particle blending and spherical agglomeration. Appl Energy 191:239–250

Guo-Qiang TW (2014) Preparation and characterization of sodium sulfate/silica composite as a shape-stabilized phase change material by sol–gel method Chin J Chem Eng 22:360–364

Fan S, Gao H, Dong W, Tang J, Wang J, Yang M, Wang G (2017) Shape‐stabilized phase change materials based on stearic acid and mesoporous hollow SiO2 microspheres (SA/SiO2) for thermal energy storage. Eur J Inorg Chem 14:2138–2143

Zhang Y, Zhang J, Li X, Wu X (2019) Preparation of hydrophobic lauric acid/SiO2 shape-stabilized phase change materials for thermal energy storage. J Energy Storage 21:611–617

Nurten Ş, Paksoy H (2017) Solar Energy Materials & Solar Cells Determining influences of SiO2 encapsulation on thermal energy storage properties of different phase change materials. 159:1–7

Li B, Liu T, Hu L, Wang Y, Gao L (2013) Fabrication and properties of microencapsulated paraffin@ SiO2 phase change composite for thermal energy storage. ACS Sustain. Chem Eng 1(3):374–380

Milian YE, Reinaga N, Grágeda M, Ushak S (2019) Development of new inorganic shape stabilized phase change materials with LiNO3 and LiCl salts by sol-gel method. J Sol–Gel Sci Technol. JSST-D-19-00199R1.

Cummins W, Duggan P, Mcloughlin P (2005) A comparative study of the potential of acrylic and sol–gel polymers for molecular imprinting. Anal Chim Acta 542:52–60

Guardia L, Bad R (2006) Molecular imprinted ormosils for nafcillin recognition by room temperature phosphorescence optosensing. Biosens Bioelectron 21:1822–1829

Wang ZM, Li L, Zheng BS, Normakhamatov N, Guo SY (2007) Preparation and anticoagulation activity of sodium cellulose sulfate. Int J Biol Macromol 41(4):376–382

Saito Y, Kobayashi K, Maruyama T (1982) DTA and X-ray studies on the phase transition in undoped and yttrium-doped sodium sulfates. Thermochim Acta 53(3):289–297

Jabbari-Hichri A, Bennici S, Auroux A (2015) Enhancing the heat storage density of silica–alumina by addition of hygroscopic salts (CaCl2, Ba(OH)2, and LiNO3). Sol Energ Mat Sol Cell 140:351–360

Jianfeng WU, Jian LI, Xiaohong XU, Lanfang Y, Jufang WU (2009) Molten salts/ceramic-foam matrix composites by melt infiltration method as energy storage material. J Wuhan Univ Technol-Mater Sci 24(4):651–653. https://doi.org/10.1007/s11595-009-4651-2

Acknowledgements

The work is partially funded by the Chilean government CONICYT/FONDAP No 15110019, CONICYT/FONDECYT REGULAR N°1170675, and CONICYT/PCI/REDES N°170131. YM would like to thanks CONICYT/BECA DE DOCTORADO NACIONAL 2015 N°21150240 for his doctorate scholarship, CORFO 16ENI2-71940 INGENIERIA2030 projects.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Milian, Y.E., Ushak, S. Design of synthesis route for inorganic shape-stabilized phase change materials. Direct sol–gel process versus vacuum impregnation method. J Sol-Gel Sci Technol 94, 67–79 (2020). https://doi.org/10.1007/s10971-019-05119-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-019-05119-8