Abstract

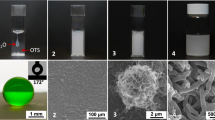

Here, we report a multifunctional superhydrophobic material achieved through the in situ growth of micro-nano-SiO2 particles from the surface of a preswollen silicone rubber sheet by sol–gel methods. The contact angles of the sheets reached 162°. The scanning electron microscopy (SEM) photographs showed that 0.8–1 μm SiO2 microspheres grew in situ on the surface of the silicone rubber sheets. The microspheres had 30–70 nm nanoscale bulges on their surfaces that formed micro-nano-structures, like a “lotus leaf”. The sizes of the micro-SiO2 particles and nanobulges were both controllable. The superhydrophobic sheets showed excellent water repellency and self-cleaning performance and exhibited satisfactory durability against mechanical abrasion, rubbing, bending, and long-term underwater storage. The mechanical robustness was attributed to a thick micro-nano-SiO2 layer formed on the surface instead of a monolayer hydrophobic coating. The superhydrophobic rubber sheets were not fluorinated, demonstrated robustness and elasticity, were easy to prepare, and were expected to provide unique advantages for a wide range of applications in biomedicine, energy and electronic devices.

The superhydrophobic silicone sheet has been achieved by the in situ growth of micro-nano SiO2 particles from the surface of a preswollen silicone sheet. The microspheres pack together and form a dense layer on the surface of silicone sheets.

Highlights

-

A multi-performance superhydrophobic rubber sheet is prepared.

-

Superhydrophobicity is achieved by growing lotus-like structure on cured rubber.

-

Morphologies of the lotus-like structure are controllable.

-

Superhydrophobic sheets have good durability against various mechanical damages.

Similar content being viewed by others

References

Jin M, Feng X, Xi J et al. (2005) Super-hydrophobic PDMS surface with ultra-low adhesive force. Macromol Rapid Commun 26:1805–1809

Roach P, Shirtcliffe NJ, Newton MI (2008) Progess in superhydrophobic surface development. Soft Matter 4(2):224–240

Wang L, Urata C, Sato T et al. (2017) Self-healing superhydrophobic materials showing quick damage recovery and long-term durability. Langmui 33(38):9972–9979

Yan YY, Gao N, Barthlott W (2011) Mimicking natural superhydrophobic surfaces and grasping the wetting process: a review on recent progress in preparing superhydrophobic surface. Adv Colloid Interface Sci 169:80–105

Su B, Tian Y, Jiang L (2016) Bioinspired Interfaces with superwettability: from materials to chemistry. J Am Chem Soc 138(6):1727

Zheng Y, Gao X, Jiang L (2007) Directional adhesion of superhydrophobic butterfly wings. Soft Matter 3(2):178–182

Gao X, Yan X, Yao X et al. (2010) The dry‐style antifogging properties of mosquito compound eyes and artificial analogues prepared by soft lithography. Adv Mater 19(17):2213–2217

Gao X, Jiang L (2004) Biophysics: water-repellent legs of water striders. Nature 432(7013):36

Li SY, Li Y, Wang J et al. (2016) Fabrication of pinecone-like structure superhydrophobic surface on titanium substrate and its self-cleaning property. Chem Eng J 290:82–90

Xue CH, Ji PT, Zhang P et al. (2013) Fabrication of superhydrophobic and superoleophilic textiles for oil-water separation. Appl Surf Sci 284(11):464–471

Zhang Z, Ge B, Men X et al. (2016) Mechanically durable, superhydrophobic coatings prepared by dual-layer method for anti-corrosion and self-cleaning. Colloids Surf A Physicochem Eng Asp 490(4):182–188

Esmailzadeh S, Khorsand S, Raeissi K et al. (2015) Microstructural evolution and corrosion resistance of super-hydrophobic electrodeposited nickel films. Surf Coat Technol 283:337–346

Oláh A, Hillborg H, Vancso GJ (2005) Hydrophobic recovery of UV/ozone treated poly(dimethylsiloxane): adhesion studies by contact mechanics and mechanism of surface modification. Appl Surf Sci 239(3):410–423

Feng L, Zhang Z, Mai Z et al. (2004) A super-hydrophobic and super-oleophilic coating mesh film for the separation of oil and water. Angew Chem Int Ed 43(15):2012–2014

Eremeyev VA (2016) On effective properties of materials at the nano- and microscales considering surface effects. Acta Mech 227(1):29–42

Qiu W, Xu D, Liu B et al. (2015) Fabrication of superhydrophobic surface by smoke deposition and application in oil-water separation. Rsc Adv 5(87):71329–71335

Momen G, Farzaneh M (2014) Facile approach in the development of icephobic hierarchically textured coatings as corrosion barrier. Appl Surf Sci 299:41–46

Hejazi I, Hajalizadeh B, Seyfi J et al. (2014) Role of nanoparticles in phase separation and final morphology of superhydrophobic polypropylene/zinc oxide nanocomposite surfaces. Appl Surf Sci 293(3):116–123

Ozbay S, Erbil HY (2015) Superhydrophobic and oleophobic surfaces obtained by graft copolymerization of perfluoroalkyl ethyl acrylate onto SBR rubber. Colloids Surf A Physicochem Eng Asp 481:537–546

Li J, Kim JK, Man LS (2005) Conductive graphite nanoplatelet/epoxy nanocomposites: Effects of exfoliation and UV/ozone treatment of graphite. Scr Mater 53(2):235–240

Zylka P (2014) On the surface performance of superhydrophobic silicone rubber specimens fabricated by direct replica method. IEEE Trans Dielectr Electr Insul 21(3):1183–1188

Hoshian S, Jokinen V, Franssila S (2016) Robust hybrid elastomer/metal-oxide superhydrophobic surfaces. Soft Matter 12:6526–6535

Xiguang Z, Zhanjian L, Xiaoying Z et al. (2018) High-adhesive superhydrophobic litchi-like coatings fabricated by in-situ growth of nano-silica on polyethersulfone surface. Chem Eng J 343:699–707

Jie J, Xi Y, Xu H et al. (2017) A highly stretchable and robust non-fluorinated superhydrophobic surface. J Mater Chem A 5:16273–16280

Hoshian S, Jokinen V, Somerkivi V et al. (2015) Robust superhydrophobic silicon without a low surface-energy hydrophobic coating. ACS Appl Mater Interfaces 7(1):941–949

Li XH, Chen GM, Ma YM et al. (2006) Preparation of superhydrophobic poly(vinyl chloride) surface via solvent-nonsolvent coating. Polymer 47:506–509

Li C, Xie B, Chen J (2017) Graphene-decorated silica stabilized stearic acid as a thermal energy storage material. RSC Adv 7(48):30142–30151

Neinhuis C, Barthlott W (1997) Characterization and distribution of water-repellent, self-cleaning plant surfaces. Ann Bot 79(6):667–677

Ramakrishna S, Kumar KSS, Mathew D et al. (2015) A robust, melting class bulk superhydrophobic material with heat-healing and self-cleaning properties. Sci Rep 5:1–11

Acknowledgements

The authors acknowledge financial support through the Key Research and Development Project of Shandong Province (2018GSF117019) and the Key Laboratory of Rubber-Plastics, Ministry of Education/Shandong Provincial Key Laboratory of Rubber-plastics (KF201704).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, J., Shi, X., Du, Y. et al. A robust, flexible superhydrophobic sheet fabricated by in situ growth of micro-nano-SiO2 particles from cured silicone rubber. J Sol-Gel Sci Technol 91, 208–215 (2019). https://doi.org/10.1007/s10971-019-05010-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-019-05010-6