Abstract

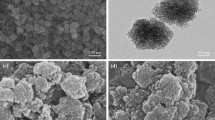

An in situ shape-stabilized phase change material (ssPCM) from polyethylene glycol (PEG) has been produced by sol–gel method. The inorganic matrix was in situ formed from tetraethyl orthosilicate (TEOS), controlling the condensation rate in a second alkaline step using NaOH. ssPCMs having a latent heat up to 113.8 J/g were synthetized using a sol with a molar ratio H2O:EtOH:H2SO4:PEG1000:TEOS of 2:0.34:0.021:0.50:1 and an equivalent ratio NaOH/H2SO4 of 1.15 for promoting the gel step. The presence of high-density hydrogen bonds between silanol groups and the ether oxygen atoms of PEG and the existence of latent heat allowed to confirm that the PEG worked in two ways. It either forms the PEG–SiO2 matrix or adsorbs onto the surface of the previous polymeric matrix, losing or conserving its latent heat, respectively. The addition of NaOH allowed to change the functionality of the silicon matrix which strongly affected the water content, the thermal stability, and the amount of active PEG in the ssPCMs, leading to an optimal neutralization condition when an equivalent ratio NaOH/H2SO4 of 1.15 was used. The obtained ssPCM has an appropriate range of operative temperatures, a high latent heat in the range of common thermoregulating materials, and a proper thermal reliability.

An in situ shape-stabilized phase change material from polyethylene glycol has been produced by sol–gel method, studying the effect of the condensation step on its final properties.

Highlights

-

Sol–gel method was used for the in situ production of a ssPCM from PEG and SiO2.

-

The sol condensation rate was controlled by adding NaOH in the neutralization step.

-

PEG works either by forming the PEG–SiO2 matrix or adsorbing onto this solid as PCM.

-

The SiO2 functionality was established by the neutralization degree.

-

The competition between PEG and SiO– by SiOH groups led to obtain an optimal ssPCM.

Similar content being viewed by others

References

Europeo P (2010) DIRECTIVA 2010/31/UE del Parlamento Europeo y del consejo, de 19 de mayo de 2010, relativa a la eficiencia energética de los edificios

Davis M (2016) PROJECT SECH-SPAHOUSEC Análisis del consumo energético del sector residencial en España (Analysis of the energy consumption of the Spanish residential sector). Build Up

Borreguero AM, Serrano A, Garrido I, Rodríguez JF, Carmona M (2014) Polymeric-SiO2-PCMs for improving the thermal properties of gypsum applied in energy efficient buildings. Energy Convers Manage 87(Suppl. C):138–144

Sutterlin W (2011) Phase change materials, a brief comparison of ice packs, salts, paraffins, and vegetable-derived phase change materials. Pharmaceutical outsourcing

Kadoono T, Ogura M (2014) Heat storage properties of organic phase-change materials confined in the nanospace of mesoporous SBA-15 and CMK-3. Phys Chem Chem Phys 16(12):5495–5498

Jamekhorshid A, Sadrameli SM, Farid M (2014) A review of microencapsulation methods of phase change materials (PCMs) as a thermal energy storage (TES) medium. Renew Sustain Energy Rev 31(Suppl. C):531–542

Fu X, Kong W, Zhang Y, Jiang L, Wang J, Lei J (2015) Novel solid-solid phase change materials with biodegradable trihydroxy surfactants for thermal energy storage. RSC Adv 5(84):68881–68889

Li W-D, Ding E-Y (2007) Preparation and characterization of cross-linking PEG/MDI/PE copolymer as solid–solid phase change heat storage material. Sol Energy Mater Sol Cells 91(9):764–768

Alkan C, Günther E, Hiebler S, Himpel M (2012) Complexing blends of polyacrylic acid-polyethylene glycol and poly(ethylene-co-acrylic acid)-polyethylene glycol as shape stabilized phase change materials. Energy Convers Manag 64(Suppl. C):364–370

Chen C, Liu W, Wang Z, Peng K, Pan W, Xie Q (2015) Novel form stable phase change materials based on the composites of polyethylene glycol/polymeric solid-solid phase change material. Sol Energy Mater Sol Cells 134(Suppl. C):80–88

Luo R, Wang S, Wang T, Zhu C, Nomura T, Akiyama T (2015) Fabrication of paraffin@SiO2 shape-stabilized composite phase change material via chemical precipitation method for building energy conservation. Energy Build 108(Suppl. C):373–380

Mehrali M, Latibari ST, Mehrali M, Metselaar HSC, Silakhori M (2013) Shape-stabilized phase change materials with high thermal conductivity based on paraffin/graphene oxide composite. Energy Convers Manag 67:275–282

Feng L, Zhao W, Zheng J, Frisco S, Song P, Li X (2011) The shape-stabilized phase change materials composed of polyethylene glycol and various mesoporous matrices (AC, SBA-15 and MCM-41). Sol Energy Mater Sol Cells 95(12):3550–3556

Huang P, Guo Y, Quirk RP, Ruan J, Lotz B, Thomas EL, Hsiao BS, Avila-Orta CA, Sics I, Cheng SZD (2006) Comparison of poly(ethylene oxide) crystal orientations and crystallization behaviors in nano-confined cylinders constructed by a poly(ethylene oxide)-b-polystyrene diblock copolymer and a blend of poly(ethylene oxide)-b-polystyrene and polystyrene. Polymer 47(15):5457–5466

Li B, Liu T, Hu L, Wang Y, Nie S (2013) Facile preparation and adjustable thermal property of stearic acid–graphene oxide composite as shape-stabilized phase change material. Chem Eng J 215-216:819–826

Weng Z, Wu K, Luo F, Xiao F, Zhang Q, Wang S, Lu M (2018) Fabrication of high thermal conductive shape-stabilized polyethylene glycol/silica phase change composite by two-step sol gel method. Compos Part A 110:106–112

Catauro M, Bollino F, Papale F, Gallicchio M, Pacifico S (2015) Influence of the polymer amount on bioactivity and biocompatibility of SiO2/PEG hybrid materials synthesized by sol–gel technique. Mater Sci Eng: C 48(Suppl. C):548–555

Borreguero AM, Rodríguez JF, Valverde JL, Arevalo R, Peijs T, Carmona M (2011) Characterization of rigid polyurethane foams containing microencapsulated Rubitherm® RT27: catalyst effect. Part II. J Mater Sci 46(2):347–356

Tang B, Cui J, Wang Y, Jia C, Zhang S (2013) Facile synthesis and performances of PEG/SiO2 composite form-stable phase change materials. Sol Energy 97(Suppl. C):484–492

Wang J, Yang M, Lu Y, Jin Z, Tan L, Gao H, Fan S, Dong W, Wang G (2016) Surface functionalization engineering driven crystallization behavior of polyethylene glycol confined in mesoporous silica for shape-stabilized phase change materials. Nano Energy 19(Suppl. C):78–87

Li J, He L, Liu T, Cao X, Zhu H (2013) Preparation and characterization of PEG/SiO2 composites as shape-stabilized phase change materials for thermal energy storage. Sol Energy Mater Sol Cells 118(Suppl. C):48–53

Parida SK, Mishra BK (1998) Adsorption of styryl pyridinium dyes on polyethylene-glycol-treated silica. Colloids Surf A 134(3):249–255

Fang G, Li H, Chen Z, Liu X (2011) Preparation and properties of palmitic acid/SiO2 composites with flame retardant as thermal energy storage materials. Sol Energy Mater Sol Cells 95(7):1875–1881

Guo Q, Wang T (2014) Preparation and characterization of sodium sulfate/silica composite as a shape-stabilized phase change material by sol-gel method. Chin J Chem Eng 22(3):360–364

Tseng TK, Lin YS, Chen YJ, Chu H (2010) A review of photocatalysts prepared by sol-gel method for VOCs removal. Int J Mol Sci 11(6):2336–2361

Núñez-Regueira L, Gracia-Fernández CA, Gómez-Barreiro S (2005) Use of rheology, dielectric analysis and differential scanning calorimetry for gel time determination of a thermoset. Polymer 46(16):5979–5985

Brinker CJ, Scherer GW (2013) Sol-gel science: the physics and chemistry of sol-gel processing. Academic Press Limited, London

Danks AE, Hall SR, Schnepp Z (2016) The evolution of 'sol-gel' chemistry as a technique for materials synthesis. Mater Horiz 3(2):91–112

Brinker CJ (1988) Hydrolysis and condensation of silicates: Effects on structure. J Non-Cryst Solids 100(1):31–50

McDonagh C, Sheridan F, Butler T, MacCraith BD (1996) Characterisation of sol-gel-derived silica films. J Non-Cryst Solids 194(1):72–77

Klein LC (1985) Sol-gel processing of silicates. Annu Rev Mater Sci 15(1):227–248

Iler RK (1979) The chemistry of silica. John Wiley and Sons, New York

Goerme TML (2011) Nanotecnología y nanomedicina: la ciencia del futuro hoy. Arkhé

Sarier N, Arat R, Menceloglu Y, Onder E, Boz EC, Oguz O (2016) Production of PEG grafted PAN copolymers and their electrospun nanowebs as novel thermal energy storage materials. Thermochim Acta 643(Suppl. C):83–93

Smith AL (1960) Infrared spectra-structure correlations for organosilicon compounds. Spectrochim Acta 16(1):87–105

Valdés BSG, Guerra M, Mieres G, Alba L, Brown A, Rangel-Vázquez NA, Sosa M, de la Hoz Y (2008) Caracterización estructural de poliuretanos mediante espectroscopia ftir y rmn (h y c 13). Rev Iberoam polím 9:4

Fidalgo A, Ilharco LM (2001) The defect structure of sol–gel-derived silica/polytetrahydrofuran hybrid films by FTIR. J Non-Cryst Solids 283(1):144–154

Schaefer D (1989) What factors control the structure of silica aerogels?. Le J Phys Colloq 50(C4):C4–121. C124-126

Schubert U (2015) Chemistry and fundamentals of the sol–gel process. The sol-gel handbook-synthesis, characterization, and applications: synthesis, characterization and applications, 3-Volume Set, p. 1–28

Peng L, Qisui W, Xi L, Chaocan Z (2009) Investigation of the states of water and OH groups on the surface of silica. Colloids Surf A 334(1):112–115

Lowe BM, Skylaris C-K, Green NG (2015) Acid-base dissociation mechanisms and energetics at the silica–water interface: an activationless process. J Colloid Interface Sci 451:231–244

Duval Y, Mielczarski JA, Pokrovsky OS, Mielczarski E, Ehrhardt JJ (2002) Evidence of the existence of three types of species at the quartz−aqueous solution interface at pH 0−10: XPS surface group quantification and surface complexation modeling. J Phys Chem B 106(11):2937–2945

Sulpizi M, Gaigeot M-P, Sprik M (2012) The silica–water interface: how the silanols determine the surface acidity and modulate the water properties. J Chem Theory Comput 8(3):1037–1047

Du Q, Freysz E, Shen YR (1994) Vibrational spectra of water molecules at quartz/water interfaces. Phys Rev Lett 72(2):238–241

Parida SK, Dash S, Patel S, Mishra BK (2006) Adsorption of organic molecules on silica surface. Adv Colloid Interface Sci 121(1):77–110

Huang Y, Santore MM (2002) Dynamics in adsorbed layers of associative polymers in the limit of strong backbone−surface attractions. Langmuir 18(6):2158–2165

Borreguero AM, Valverde JL, Rodríguez JF, Barber AH, Cubillo JJ, Carmona M (2011) Synthesis and characterization of microcapsules containing Rubitherm®RT27 obtained by spray drying. Chem Eng J 166(1):384–390

Xiong W, Chen Y, Hao M, Zhang L, Mei T, Wang J, Li J, Wang X (2015) Facile synthesis of PEG based shape-stabilized phase change materials and their photo-thermal energy conversion. Appl Therm Eng 91(Suppl. C):630–637

Acknowledgements

We gratefully acknowledge funding from the Ministry of Economy and Competitiveness of Spain through the project Ref. CTQ2015-69299-R. The authors also acknowledge the support from the grant from the University of Castilla-La Mancha for the thesis studies of Angel Serrano.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Serrano, A., Martín del Campo, J., Peco, N. et al. Influence of gelation step for preparing PEG–SiO2 shape-stabilized phase change materials by sol–gel method. J Sol-Gel Sci Technol 89, 731–742 (2019). https://doi.org/10.1007/s10971-018-4866-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4866-9