Abstract

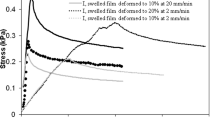

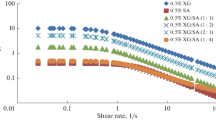

The behaviour of alginate gel film in response to the tensile load is analysed in this paper. The bubbles of 0.5 mm diameter were embedded in the film by the fluidic method prior to gelation, thus providing uniform voidage over the entire film. Further, the intrinsic porosity of the gel matrix around the voids was varied by removing water through either evaporation under vacuum, or employing lyophilisation. The Poisson’s ratio and the modulus of elasticity were estimated from direct measurements. The viscoelasticity of the gel matrix was characterized from stress-relaxation measurement. The transient response to tensile loading and the evolution of stress contours were studied through numerical simulation in ANSYS. The ultimate strength was studied for the gel films with embedded voids of different sizes. The numerical simulations were validated by experimental measurements.

Highlights

-

Alginate films with uniform macroporosity were fabricated.

-

The macroporosity was varied by controlling the introduction of bubbles.

-

The film’s microporosity was varied through a solvent removal mechanism.

-

Stress–strain behavior, image correlation, and stress-relaxation studies were reported.

-

Viscoelastic stress–strain behavior was explained through generalized Maxwell model.

-

The evolution of stress profiles around the voids was studied from simulation.

-

Predicted ultimate strength of the film was verified with the experimental data.

Similar content being viewed by others

References

Dong ZF, Wang Q, Du YM (2006) Alginate/gelatin blend films and their properties for drug controlled release. J Membr Sci 280(1–2):37–44

Khattak SF, Chin KS, Bhatia SR, Roberts SC (2007) Enhancing oxygen tension and cellular function in alginate cell encapsulation devices through the use of perfluorocarbons. Biotechnol Bioeng 96:156–166

Baruch L, Machluf M (2006) Alginate–chitosan complex coacervation for cell encapsulation: effect on mechanical properties and on long-term viability. Biopolymers 82:570–9

De Groot K (1988) Effect of porosity and physicochemical properties on the stability, resorption, and strength of calcium phosphate ceramics. Ann N Y Acad Sci 523:227–33

Chung HJ, Park TG (2007) Surface engineered and drug releasing pre-fabricated scaffolds for tissue engineering. Adv Drug Deliv Rev 59:249–262

Lin KH, Hong WJ. Method and device of fabricating three dimensional scaffolds, US Patent No. US20110285047 A1, published on Nov 24, 2011

Chung K, Mishra NC, Wang C, Lin F, Lin K (2009) Fabricating Scaffolds by microfluidics. BioMicrofluidics 3:022403

Wang X, Li X, Stride E, Juang J, Edirisinghe M, Schroeder C, Best S, Cameron R, Waller D, Donald A (2010) Novel preparation and characterization of porous alginate films. Carbohydr Polym 79:989–997

Martynov S, Xialiang W, Stride EP, Edirisinghe MJ (2010) Preparation of a mico-porous alginate gel using a microfluidic bubbling device. Int J Food Eng 6(3):1–12

Stone HA, Anna SL, Bontoux N, Link DR, Weitz DA, Gitlin I, Kumacheva E, Garstecki P, Diluzio R, Whitesides M Method and apparatus for fluid dispersion. Patent No. US8,337,778 B2, dated Dec 25, 2012

Patra S, Bal DK, Ganguly S (2015) Bubble formation in complex fluids using an orifice in throat arrangement. Exp Therm Fluid Sci 64:62–69

Kuo CK, Ma PX (2001) Ionically cross-linked alginate hydrogels as scaffolds for tissue engineering: 1. Structure, gelation rate and mechanical properties. Biomaterials 22:511–521

Draget KI, Ostgaard K, Smidsrod O (1991) Homogeneous alginate gels: a technical approach. Carbohyd Polym 14:159–178

Sheridan MH, Shea LD, Peters MC, Mooney DJ (2000) Bioabsorbable polymer scaffolds for tissue engineering capable of sustained growth factor delivery. J Control Release 64:91–102

Dohnal J, Stepanek F (2010) Inkjet fabrication and characterization of calcium alginate microcapsules. Powder Technol 200:254–259

Li RH, Altreuter DH, Gentile FT (1996) Transport characterization of hydrogel matrices for cell encapsulation. Biotechnol Bioeng 50(4):365–73

Wang L, Shelton RM, Cooper PR, Lawson M, Triffitt JT, Barralet JE (2003) Evaluation of sodium alginate for bone marrow cell tissue engineering. Biomaterials 24:3475–81

Webber RE, Shull KR (2004) Strain dependence of the viscoelastic properties of alginate hydrogels. Macromolecules 37:6153–6160

Drury JL, Boonthekul T, Mooney DJ (2005) The tensile properties of alginate hydrogels. J Biomech Eng 127:220

Zhang D, Eggleton CD, Arola DD (2002) Evaluating the mechanical behavior of arterial tissue using digital image correlation. Exp Mech 42(4):409–16

Cloyd JM, Malhotra NR, Weng L, Chen W, Mauck RL, Elliott DM (2007) Material properties in unconfined compression of human nucleus pulposus, injectable hyaluronic acid-based hydrogels and tissue engineering scaffolds. Eur Spine J 16(11):1892–1898

Nguyen VB, Wang CX, Zhang Z (2009) Mechanical properties of single alginate microspheres determined by microcompression and finite element modelling. Chem Eng Sci 64:821–829

LeRoux MA, Guilak F, Setton LA (1999) Compressive and shear properties of alginate gel: effects of sodium ions and alginate concentration. J Biomed Mater Res 47:46–53

Zhao XH, Huebsch N, Mooney DJ, Suo ZG (2010) Stress-relaxation behavior in gels with ionic and covalent crosslinks. J Appl Phys 107:063509/1–5

Kim GW, Do G, Bae Y, Sagara Y (2012) Viscoelastic properties of frozen-thawed agar/agar-gelatin gels based on binary-phase virtual structure. Int J Refrig 35(8):2349–2357

Yoon JW, Cai SQ, Suo ZG, Hayward RH (2010) Poroelastic swelling kinetics of thin hydrogel layers: comparison of theory and experiment. Soft Matter 6:6004–6012

Wang, X, Hong, W (2012) A visco-poroelastic theory for polymeric gels. Proc R Soc A Math Phys Eng Sci 468:3824–3841.

Carew EO, Talman EA, Boughner DR, Vesely I (1999) Quasilinear viscoelastic theory applied to internal shearing of porcine aortic valve leaflets. J Biomech 121(4):386–392

Drapaca C, Tenti G, Rohlf K, Sivaloganathan S (2006) A quasilinear viscoelastic constitutive equation for the brain: application to hydrocephalus. J Elast 85:65–83

Nekouzadeh A, Pryse KM, Genin GM (2007) A simplified approach to quasilinear viscoelastic modelling. J Biomech 40:3070–3078

Guilak F, Mow VC (2000) The mechanical environment of the chondrocyte: a biphasic finite element model of cell-matrix interactions in articular cartilage. J Biomech 33:1663e73

Budyn E, Hoc T, Jonvaux J (2008) Fracture strength assessment and aging signs detection in human cortical bone using an X-FEM multiple scale approach. Comput Mech 42(4):579–591

Kumar KCN, Tandon T, Silori P, Shaikh A (2015) Biomechanical stress analysis of a human femur bone using ANSYS. Mater Today Proc 2(4–5):2115–2120

Moresi M, Bruno M (2007) Characterisation of alginate gels using quasi-static and dynamic methods. J Food Eng 82:298–309

Cai S, Hu Y, Zhao X, Suo Z (2010) Poroelasticity of a covalently cross-linked alginate hydrogel under compression. J Appl Phys 108:113514

Patra S, Bal DK, Ganguly S (2016) Diffusion in and around alginate and chitosan films with embedded sub-millimeter voids. Mater Sci Eng C Mater Biol Appl 59:61–69

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Banerjee, A., Patra, S. & Ganguly, S. Mechanical behaviour of a hydrogel film with embedded voids under the tensile load. J Sol-Gel Sci Technol 87, 665–675 (2018). https://doi.org/10.1007/s10971-018-4776-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4776-x