Abstract

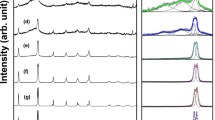

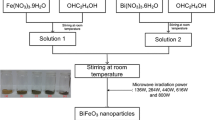

Phase-pure Aurivillius Bi5Ti3FeO15 nanoparticles were successfully prepared using a sol–gel method. Behaviours of crystallisation were characterised by XRD, DTA, FT-IR, Raman spectra and HRTEM. Mass spectrum was used to monitor the combustion products of all organics in the xerogel during calcination. An intermediate product, Bi2O2CO3, which blocks the generation of the pyrochlore phases, was confirmed by XRD patterns and IR spectra. Calculated by XRD data using the Debye–Scherrer method, the average grain size in powders calcinated at 500 °C was 17.7 nm and grew to 80.5 nm at 850 °C. The local symmetry connected to FeO6 octahedral was broken. The XRD refinement and XPS analyses inferred the valence increase of ferric ions. The maximum magnetisation of nanoparticles prepared at 850 °C was 4.2 emu/g. The field cooling (FC) and zero field cooling (ZFC) tests showed a wide range of the blocking temperature (T B) around 8–45 K answering for the lack of hump corresponding to the transition from superparamagnetism to blocking state.

Graphical Abstract

Similar content being viewed by others

References

Schmid H (1994) Ferroelectrics 162:317–338

Wang KF, Liu J-M, Ren ZF (2009) Adv Phys 58:321

Scott JF, Blinc R (2011) J Phys Condens Matter 23:113202

Eerenstein W, Mathur ND, Scott JF (2006) Nature 442:759–765

Cheong S-W, Mostovoy M (2007) Nat Mater 6:13–20

Zheng H, Wang J, Lofland SE, Ma Z, Mohaddes-Ardabili L, Zhao T, Salamanca-Riba L, Shinde SR, Ogale SB, Bai F, Viehland D, Jia Y, Schlom DG, Wuttig M, Roytburd A, Ramesh R (2004) Science 303:661–663

Nan C-W, Bichurin MI, Dong S, Viehland D, Srinivasan G (2008) J Appl Phys 103:31101

Wang J, Neaton JB, Zheng H, Nagarajan V, Ogale SB, Liu B, Viehland D, Vaithyanathan V, Schlom DG, Waghmare UV, Spaldin NA, Rabe KM, Wuttig M, Ramesh R (2003) Science 299:1719–1722

de Araujo CA-P, Cuchiaro JD, McMillan LD, Scott MC, Scott JF (1995) Nature 374:627–629

Dobal PS, Katiyar RS (2002) J Raman Spectrosc 33:405–423

Ke H, Zhou Y, Jia DC, Wang W, Xu XQ, Ye F (2005) J Solgel Sci Technol 34:131–136

Deepak N, Carolan P, Keeney L, Pemble ME, Whatmore RW (2015) J Mater Chem C 3:5727–5732

Birenbaum AY, Ederer C (2014) Phys Rev B Condens Matter Mater Phys 90:214109

Mao X, Wang W, Sun H, Lu Y, Chen X (2011) J Mater Sci 47:2960–2965

Dong XW, Wang KF, Wan JG, Zhu JS, Liu JM (2008) J Appl Phys 103:94101

Amouri A, Abdelmoula N, Khemakhem H (2015) Ceram Int 41:10425–10433

Xiao J, Zhang H, Xue Y, Lu Z, Chen X, Su P, Yang F, Zeng X (2015) Ceram Int 41:1087–1092

Keeney L, Maity T, Schmidt M, Amann A, Deepak N, Petkov N, Roy S, Pemble ME, Whatmore RW, Johnson D (2013) J Am Ceram Soc 96:2339–2357

Keeney L, Groh C, Kulkarni S, Roy S, Pemble ME, Whatmore RW (2012) J Appl Phys 112:0–9

Jung S, Hwang S, Sung Y (2003) J Mater Res 18:1745–1748

Villegas M, Jardiel T, Caballero AC, Fernndez JF (2004) J Electroceramics 13:543–548

Tillotson T, Gash A, Simpson R, Hrubesh L, Satcher J, Poco J (2001) J Non Cryst Solids 285:338–345

Xu JH, Ke H, Jia DC, Wang W, Zhou Y (2009) J Alloys Compd 472:473–477

García-Guaderrama M, Fuentes L, Montero-Cabrera ME, Márquez-Lucero A, Villafuerte-Castrejón ME (2005) Integr Ferroelectr 71:233–239

Jang JS, Yoon SS, Borse PH, Lim KT, Hong TE, Jeong ED, Jung OS, Shim YB, Kim HG (2009) J Ceram Soc Jpn 117:1268–1272

Jartych E, Pikula T, Mazurek M, Franus W, Lisinska-Czekaj A, Czekaj D, Oleszak D, Surowiec Z, Aksenczuk A, Calka A (2016) Arch Metall Mater 61:869–874

Ding Y, Liu JS, Wang YN (2000) Appl Phys Lett 76:103–105

Su D, Zhu JS, Wang YN, Xu QY, Liu JS (2003) J Appl Phys 93:4784

Toby BH (2001) J Appl Crystallogr 34:210–213

ACLAVon Dreele (2004) Los Alamos National Laboratory Report. LAUR, p 86

Ko TY, Jun CH, Lee JS (1999) The Korean J Ceram 5(4):341–347

Ke H, Wang W, Chen L, Xu J, Jia D, Lu Z, Zhou Y (2010) J. Solgel Sci Technol 53:135–140

Zhang H, Ke H, Wang W, Jia D, Zhou Y (2016) J Am Ceram Soc 99:2334–2340

Hou J, Kumar RV, Qu Y, Krsmanovic D (2009) J Nanopart Res 12:563–571

Ti R, Lu X, He J, Huang F, Wu H, Mei F, Zhou M, Li Y, Xu T, Zhu J (2015) J Mater Chem C 3:11868–11873

Kooriyattil S, Pavunny SP, Barrionuevo D, Katiyar RS (2014) J Appl Phys 116:0–6

Graves PR, Hua G, Myhra S, Thompson JG (1995) J Solid State Chem 114:112–122

Bokolia R, Thakur OP, Rai VK, Sharma SK, Sreenivas K (2015) Ceram Int 41:6055–6066

Jiang PP, Zhang XL, Chang P, Hu ZG, Bai W, Li YW, Chu JH (2014) J Appl Phys 115:144101–144103

Zheng HW, Liu SJ, Yin GS, Wang WC, Diao CL, Gu YZ, Zhang WF (2011) J Solgel Sci Technol 59:290–296

Nemanich RJ, Solin SA, Martin RichardM (1981) Phys Rev B 23:6348–6356

Biesinger MC, Payne BP, Grosvenor AP, Lau LWM, Gerson AR, Smart RSC (2011) Appl Surf Sci 257:2717–2730

Uhlig I, Szargan R, Nesbitt HW, Laajalehto K (2001) Appl Surf Sci 179:222–229

Xuan SH, Wang YXJ, Yu JC, Leung KCF (2009) Chem Mater 21:5079–5087

Gittleman JI, Abeles B, Bozowski S (1974) Phys Rev B 9:3891–3897

Barra A-L, Debrunner P, Gatteschi D, Schulz CE, Sessoli R (1996) Europhys Lett 35:133–138

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NSFC, Grant No. 51472063, 51772065 and 51621091).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Zhang, H., Ke, H., Ying, P. et al. Crystallisation process of Bi5Ti3FeO15 multiferroic nanoparticles synthesised by a sol–gel method. J Sol-Gel Sci Technol 85, 132–139 (2018). https://doi.org/10.1007/s10971-017-4530-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-017-4530-9