Abstract

HKUST-1@silica aerogel composite pellets (HKUST-1@SiO2) were prepared by the coupled sol–gel and water-in-oil emulsion method using supercritical CO2 drying. The structure and morphology of HKUST-1@SiO2 were characterized by X-Ray diffraction, scanning electron microscopy and low-temperature nitrogen adsorption. According to these data, the composite represents physically dispersed micron-sized domains of HKUST-1 in the silica aerogel pellets. It was shown that the HKUST-1@SiO2 pellets can be used as a catalyst for isomerization of styrene oxide to phenyl acetaldehyde in a continuous flow reactor.

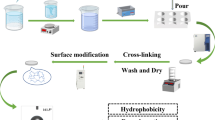

Graphical abstract

Similar content being viewed by others

References

Corma A, García H, Llabrés i Xamena FX (2010) Engineering metal organic frameworks for heterogeneous catalysis. Chem Rev 110:4606–4655. doi:10.1021/cr9003924

Dhakshinamoorthy A, Alvaro M, Garcia H (2012) Commercial metal–organic frameworks as heterogeneous catalysts. Chem Commun 48:11275. doi:10.1039/c2cc34329k

Lee J, Farha OK, Roberts J et al (2009) Metal–organic framework materials as catalysts. Chem Soc Rev 38:1450. doi:10.1039/b807080f

Chui SS (1999) A Chemically functionalizable nanoporous material [Cu3(TMA)2(H2O)3]n. Science 283(80-):1148–1150. doi:10.1126/science.283.5405.1148

Schlichte K, Kratzke T, Kaskel S (2004) Improved synthesis, thermal stability and catalytic properties of the metal-organic framework compound Cu3(BTC)2. Microporous Mesoporous Mater 73:81–88. doi:10.1016/j.micromeso.2003.12.027

Dhakshinamoorthy A, Alvaro M, Garcia H (2010) Metal-organic frameworks as efficient heterogeneous catalysts for the regioselective ring opening of epoxides. Chem - A Eur J 16:8530–8536. doi:10.1002/chem.201000588

Dhakshinamoorthy A, Alvaro M, Garcia H (2010) Metal organic frameworks as solid acid catalysts for acetalization of aldehydes with methanol. Adv Synth Catal 352:3022–3030. doi:10.1002/adsc.201000537

Alaerts L, Séguin E, Poelman H et al (2006) Probing the lewis acidity and catalytic activity of the metal–organic framework [Cu3(btc)2] (BTC=Benzene-1,3,5-tricarboxylate). Chem - A Eur J 12:7353–7363. doi:10.1002/chem.200600220

Pérez-Mayoral E, Čejka J (2011) [Cu3(BTC)2]: A metal-organic framework catalyst for the friedländer reaction. ChemCatChem 3:157–159. doi:10.1002/cctc.201000201

Sachse A, Ameloot R, Coq B et al (2012) In situ synthesis of Cu–BTC (HKUST-1) in macro-/mesoporous silica monoliths for continuous flow catalysis. Chem Commun 48:4749. doi:10.1039/c2cc17190b

Finsy V, Ma L, Alaerts L et al (2009) Separation of CO2/CH4 mixtures with the MIL-53(Al) metal–organic framework. Microporous Mesoporous Mater 120:221–227. doi:10.1016/j.micromeso.2008.11.007

Hessel V (2009) Novel process windows - gate to maximizing process intensification via flow chemistry. Chem Eng Technol 32:1655–1681. doi:10.1002/ceat.200900474

Baxendale IR, Brocken L, Mallia CJ (2013) Flow chemistry approaches directed at improving chemical synthesis. Green Process Synth. doi:10.1515/gps-2013-0029

Wiles C, Watts P (2014) Continuous process technology: a tool for sustainable production. Green Chem 16:55–62. doi:10.1039/C3GC41797B

Ameloot R, Liekens A, Alaerts L et al. (2010) Silica-MOF composites as a stationary phase in liquid chromatography. Eur J Inorg Chem 2010:3735–3738. doi:10.1002/ejic.201000494

Ahmed A, Forster M, Clowes R et al. (2013) Silica SOS@HKUST-1 composite microspheres as easily packed stationary phases for fast separation. J Mater Chem A 1:3276. doi:10.1039/c2ta01125e

Tanaka K, Muraoka T, Hirayama D, Ohnish A (2012) Highly efficient chromatographic resolution of sulfoxides using a new homochiral MOF–silica composite. Chem Commun 48:8577. doi:10.1039/c2cc33939k

Aguado S, Canivet J, Farrusseng D (2010) Facile shaping of an imidazolate-based MOF on ceramic beads for adsorption and catalytic applications. Chem Commun 46:7999. doi:10.1039/c0cc02045a

O’Neill LD, Zhang H, Bradshaw D (2010) Macro-/microporous MOF composite beads. J Mater Chem 20:5720. doi:10.1039/c0jm00515k

Li L, Yao J, Xiao P et al (2013) One-step fabrication of ZIF-8/polymer composite spheres by a phase inversion method for gas adsorption. Colloid Polym Sci 291:2711–2717. doi:10.1007/s00396-013-3024-8

Nuzhdin AL, Shalygin AS, Artiukha EA et al (2016) HKUST-1 silica aerogel composites: novel materials for the separation of saturated and unsaturated hydrocarbons by conventional liquid chromatography. RSC Adv 6:62501–62507. doi:10.1039/C6RA06522H

Ulker Z, Erucar I, Keskin S, Erkey C (2013) Novel nanostructured composites of silica aerogels with a metal organic framework. Microporous Mesoporous Mater 170:352–358. doi:10.1016/j.micromeso.2012.11.040

Liu M, Gan L, Pang Y et al. (2008) Synthesis of titania–silica aerogel-like microspheres by a water-in-oil emulsion method via ambient pressure drying and their photocatalytic properties. Colloids Surf A Physicochem Eng Asp 317:490–495. doi:10.1016/j.colsurfa.2007.11.024

Alnaief M, Smirnova I (2011) In situ production of spherical aerogel microparticles. J Supercrit Fluids 55:1118–1123. doi:10.1016/j.supflu.2010.10.006

Hong SK, Yoon MY, Hwang HJ (2011) Fabrication of spherical silica aerogel granules from water glass by ambient pressure drying. J Am Ceram Soc 94:3198–3201. doi:10.1111/j.1551-2916.2011.04765.x

Yu Y, Zhu M, Liang W et al (2015) Synthesis of silica–titania composite aerogel beads for the removal of Rhodamine B in water. RSC Adv 5:72437–72443. doi:10.1039/C5RA13625C

Thommes M, Kaneko K, Neimark A V., et al (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl Chem. doi:10.1515/pac-2014-1117

Gou M-L, Wang R, Qiao Q et al (2015) Effect of mesoporosity by desilication on acidity and performance of HZSM-5 in the isomerization of styrene oxide to phenylacetaldehyde. Microporous Mesoporous Mater 206:170–176. doi:10.1016/j.micromeso.2014.12.006

Hoang PH, Xuan BN (2015) Selective isomerization of epoxides using magnetically recyclable ZSM-5 zeolite catalyst. RSC Adv 5:78441–78447. doi:10.1039/c5ra16922d

Costa VV, da Silva Rocha KA, Kozhevnikov IV et al. (2010) Isomerization of styrene oxide to phenylacetaldehyde over supported phosphotungstic heteropoly acid. Appl Catal A Gen 383:217–220. doi:10.1016/j.apcata.2010.06.005

González-Pérez AB, Grechkin A, de Lera AR (2017) Rearrangement of vinyl allene oxide geometric isomers to cyclopentenones. Further computational insights with biologically relevant model systems. Org Biomol Chem 15:2846–2855. doi:10.1039/c6ob02791a

Schlichte K, Kratzke T, Kaskel S (2004) Improved synthesis, thermal stability and catalytic properties of the metal-organic framework compound Cu3(BTC)2. Microporous and Mesoporous Materials 17:81–88. doi:10.1016/j.micromeso.2003.12.027

Chamoumi M, Brunel D, Moreau P, Solofo J (1991) Rearrangement of epoxides using modified zeolites. Stud Surf Sci Catal 59:573–579. doi:10.1016/S0167-2991(08)61167-2

Vannice MA (2005) Kinetics of Catalytic Reactions. Springer, New York, NY

Liang CY, Krimm S (1958) Infrared spectra of high polymers. VI. Polystyrene. J Polym Sci 27:241–254. doi:10.1002/pol.1958.1202711520

Acknowledgements

This work was conducted within the framework of SB RAS Integrated Program of Fundamental Scientific Research No. II.2 (project No. 0303-2015-0009)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Shalygin, A.S., Nuzhdin, A.L., Bukhtiyarova, G.A. et al. Preparation of HKUST-1@silica aerogel composite for continuous flow catalysis. J Sol-Gel Sci Technol 84, 446–452 (2017). https://doi.org/10.1007/s10971-017-4455-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-017-4455-3