Abstract

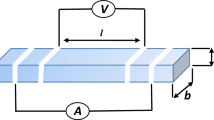

Single-phase, submicron La0.6Sr0.4CoO3−δ (LSC) powder was prepared via a polymeric complexation method at various heating/cooling rates. The optimum powder slurry was used to fabricate LSC/BCZY64/LSC half-cells using BaCe0.54Zr0.36Y0.1O2.95 (BCZY64) as the electrolyte material. The produced powder was characterized by thermal gravimetric analyzer (TGA), X-ray diffractometer (XRD) and scanning electron microscope (SEM) and the half-cell, by electrochemical impedance spectroscopy. TGA results showed that the thermal decomposition temperature (T td) increased as the heating rate increased. The minimum and maximum T td was observed at 600 °C (2 °C min−1) and 750 °C (15 °C min−1), respectively. The XRD results confirmed that a single perovskite phase of LSC formed at heating/cooling rates of 2, 5 and 10 °C min−1 at calcination temperatures of 800, 900 and 1000 °C, respectively. A single perovskite phase of LSC was not observed at a heating/cooling rate of 15 °C min−1. The smallest particle size (130–260 nm) was obtained at 800 °C with a heating/cooling rate of 5 °C min−1, as shown in the SEM micrographs. The area specific resistance of the half-cell was 2.96, 0.97, 0.48 and 0.19 Ω cm2 at 500, 600, 700 and 800 °C, respectively. This result indicates that the prepared LSC cathode has the potential to be used with the BCZY64 electrolyte for an intermediate temperature proton-conducting SOFC.

Graphical Abstract

Similar content being viewed by others

References

Zhao L, He B, Xun Z, Wang H, Peng R, Meng G, Liu X (2010) Int J Hydrog Energy 35:753–756

Sleiti AK (2010) J Power Sources 195:5719–5725

Tao Y, Shao J, Wang J, Wang WG (2008) J Power Sources 185:609–614

Heel A, Holtappels P, Graule T (2010) J Power Sources 195:6709–6718

Hayd J, Dieterle L, Guntow U, Gerthsen D, Ivers-Tiffée E (2011) J Power Sources 196:7263–7270

Ricote S, Bonanos N, Lenrick F, Wallenberg R (2012) J Power Sources 218:313–319

Ling Y, Yao X, Zhang X, Liu X, Lin B (2012) Int J Hydrog Energy 37:5940–5945

Nian Q, Zhao L, He B, Lin B, Peng R, Meng G, Liu X (2010) J Alloys Compd 492:291–294

Goupil G, Delahaye T, Gauthier G, Sala B, Joud FL (2012) Solid State Ion 209–210:36–42

Tolchard JR, Grande T (2007) Solid State Ion 178:593–599

Ricote S, Bonanos N, Rørvik PM, Haavik C (2012) J Power Sources 209:172–179

Yang L, Liu Z, Wang S, Choi Y, Zuo C, Liu M (2010) J Power Sources 195:471–474

Abdullah NA, Osman N, Hasan S, Hassan OH (2012) Int J Electrochem Sci 7:9401–9409

Shao Z, Zhou W, Zhu Z (2012) Prog Mater Sci 57:804–874

Shao J, Tao Y, Wang J, Xu C, Wang WG (2009) J Alloys Compd 484:263–267

Ge L, Ran R, Shao Z, Zhu ZH, Liu S (2009) Ceram Int 35:2809–2815

Kim JH, Park YM, Kim H (2011) J Power Sources 196:3544–3547

Samat AA, Abdullah NA, Ishak MAM, Osman N (2012) World Acad Sci Eng Technol 70:822–826

Wongmaneerung R, Yimnirun R, Ananta S (2009) Mater Chem Phys 114:569–575

Osman N, Ishak MAM, Samat AA (2013) Chem Mater Res 3:52–61

Samat AA, Safri SA, Samsudin D, Jaafar WS, Osman N (2014) Adv Mater Res 896:175–178

van Doorn RHE, Kruidhof H, Nijmeijer A, Winnubst L, Burggraaf AJ (1998) J Mater Chem 8:2109–2112

Ting-Kuo FG, Chen JG, Wang ZF, Yang HZ, Kumar TP (2004) Mater Chem Phys 87:246–255

Samat AA, Ishak MAM, Hamid HA, Osman N (2013) Adv Mater Res 701:131–135

Wang HW, Hall DA, Sale FR (1994) J Therm Anal 41:605–620

Rasooli A, Boutorabi M, Divandari M, Azarniya A (2013) Bull Mater Sci 36:301–309

Galceran M, Pujol MC, Aguiló M, Díaz F (2007) J Sol–Gel Sci Technol 42:79–88

Shaikh PA, Kolekar YD (2012) J Anal Appl Pyrolysis 93:41–46

Yang ZH, Lin YS (2005) Solid State Ion 176:89–96

Kashif I, Abdelghany A, El-said R (2009) Mater Chem Phys 115:309–312

Durán P, Capel F, Tartaj J, Gutierrez D, Moure C (2001) Solid State Ion 141–142:529–539

Bansal NP, Zhong Z (2006) J Power Sources 158:148–153

Liou YC (2004) Mater Lett 58:944–947

Acuña LM, Peña-Martínez J, Marrero-López D, Fuentes RO, Nuñez P, Lamas DG (2011) J Power Sources 196:9276–9283

Pierre AC (1998) Introduction to sol–gel processing, 1st edn. Kluwer Academic Publishers, London, pp 155–158

Katahira K, Kohchi Y, Shimura T, Iwahara H (2007) Solid State Ion 138:91–98

Zhong Z (2007) Solid State Ion 178:213–220

Acknowledgments

The authors would like to thank the Ministry of Education (MOE) of Malaysia for the Research Acculturation Collaborative Effort (RACE/2012) Grant and Fundamental Research Grant Scheme (FRGS/2014 and FRGS/2/2013/TK06/UKM/02/9). Additionally, the authors acknowledge the financial support given by the Universiti Kebangsaan Malaysia (UKM) via research sponsorships DLP-2014-004. The first author gratefully acknowledges Universiti Malaysia Perlis (UniMAP) and MOE for a PhD scholarship. Facility support from the Center for Research and Instrumentation Management (CRIM) and Fuel Cell Institute of Universiti Kebangsaan Malaysia (UKM) and Universiti Teknologi MARA (UiTM) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdul Samat, A., Somalu, M.R., Muchtar, A. et al. LSC cathode prepared by polymeric complexation method for proton-conducting SOFC application. J Sol-Gel Sci Technol 78, 382–393 (2016). https://doi.org/10.1007/s10971-015-3945-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-015-3945-4