Abstract

The development of multifunctional coatings plays a crucial role in the achievement of more competitive glasses for optical and solar application, among others. In this respect, coatings that provide high transmittance together with abrasion resistance could mean an added value to such glasses. Herein, we report design and preparation of novel multifunctional coatings that present anti-reflection (AR), scratch and abrasion resistance properties. This is achieved by a coating structure with a composite top layer comprising at least one type of metal oxide (ZrO2 or TiO2) or silane compound with low-refractive-index SiO2 layer. The above composite layer is applied onto a high refractive metal oxide layer, either titania or zirconia. The properties of the coatings were studied by different characterization techniques such as UV–visible–NIR spectrophotometer, FESEM, FIB, SEM–EDAX, haze and transmission meter, ellipsometer, pencil hardness tester, Taber Abrader and water contact angle measurement. The results indicate that the AR films produced by a bilayer system especially using a low refractive nanocomposite layer as a top layer and a high refractive layer as a bottom layer showed a high transmission in the visible range with comparatively better abrasion and scratch resistances. Moreover, the coatings developed on silicon wafer used as an absorber substrate for PV application exhibited an excellent low reflectance property, <2.5 % average reflection from 300 to 1500 nm which makes it applicable in both optical and photovoltaic systems with high mechanical stability.

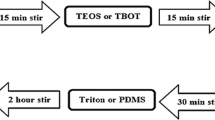

Graphical Abstract

Composite bilayer anti-reflection coatings with enhanced abrasion and scratch resistance properties.

Similar content being viewed by others

References

Nostell P, Roos A, Karlsson B (1999) Optical and mechanical properties of sol–gel antireflective films for solar energy applications. Thin Solid Films 351:170–175

Hammaberg E, Roos A (2000) Antireflection treatment of low-emitting glazing for energy efficient windows with high visible transmittance. Thin Solid Films 442:222–226

Chen D, Yan Y, Westenberg E, Niebauer D, Sakaitani N, Chaudhuri SR, Sato Y, Takamatsu M (2000) Development of anti-reflection (AR) coating on plastic panels for display applications. J Sol-Gel Sci Technol 19:77–82

Morimoto T, Sanada Y, Tomonaga H (2001) Wet chemical functional coatings for automotive glasses and cathode ray tubes. Thins Solid Films 392:214–222

Lien SY, Wu DS, Yeh WC, Liu JC (2006) Tri-layer antireflection coatings (SiO2/SiO2–TiO2/TiO2) for silicon solar cells using a sol–gel technique. Sol Energy Mater Sol Cells 90:2710–2719

Chabas A, Lombardo T, Cachier H, Pertuisot MH, Oikonomou K, Falcone R, Verita M, Geotti-Bianchini F (2008) Behaviour of self-cleaning glass in urban atmosphere. Build Environ 43:2124–2131

Prado R, Beobide G, Marcaide A, Goikoetxea J, Aranzabe A (2010) Development of multifunctional sol–gel coatings: anti-reflection coatings with enhanced self-cleaning capacity. Sol Energy Mater Sol Cells 94:1081–1088

Sakthivel S, Righeira Carnegie M, Joshi SV (2012) Indian patent 1777/DEL/2012

Bostrom T, Wackelgard E, Westin G (2003) Solution-chemical derived nickel–alumina coatings for thermal solar absorbers. Sol Energy 74:497–503

Bostrom T, Wackelgard E, Westin G (2004) Anti-reflection coatings for solution-chemically derived nickel–alumina solar absorbers. Sol Energy Mater Sol Cells 8:183–191

Nagel H, Metz A, Hezel R (2001) Porous SiO2 films prepared by remote plasma-enhanced chemical vapour deposition—a novel antireflection coating technology for photovoltaic modules. Sol Energy Mater Sol Cells 65:71–77

Ritala M, Niinisto J (2009) Atomic layer deposition. In: Jones AC, Hitchman ML (eds) Chemical vapour deposition: precursors, processes and applications. Royal Society of Chemistry, London, pp 158–206

Kesmez O, Camurlu HE, Burunkaya E, Arpac E (2009) Sol–gel preparation and characterization of anti-reflective and self-cleaning SiO2–TiO2 double-layer nanometric films. Sol Energy Mater Sol Cells 93:1833–1839

Chen D (2001) Anti-reflection (AR) coatings made by sol–gel processes: a review. Sol Energy Mater Sol Cells 68:313–336

Hinz P, Dislich H (1986) Anti-reflecting light-Scattering coatings via the sol–gel procedure. J Non-Cryst Solids 82:411–416

Rouse JH, Ferguson GH (2003) Preparation of thin silica films with controlled thickness and tuneable refractive index. J Am Chem Soc 125:15529–15536

Zhang X, Fujishima A, Jin M, Emeline AV, Murakami T (2006) Double-layered TiO2–SiO2 nanostructured films with self-cleaning and antireflective properties. J Phys Chem B 110:25148

Lee D, Rubner MF, Cohen RE (2006) All-nanoparticle thin-film coatings. Nano Lett 6:2305–2312

Bautista MC, Morales A (2003) Silica antireflective films on glass produced by the sol–gel method. Sol Energy Mater Sol Cells 80:217–225

Liu Z, Zhang X, Murakami T, Fujishima A (2008) Sol–gel SiO2/TiO2 bi-layer films with self-cleaning and antireflection properties. Sol Energy Mater Sol Cells 92:1434–1438

Walheim S, Schaffer E, Mlynek J, Steiner U (1999) Nanophase-separated polymer films as high-performance antireflection coatings. Science 283:520–522

Minoru H, Akiko Y, Hiroshi K (1988) Jpn. Patent 0247166

Xu Y, Wu D, Sun YH, Li ZH, Dong BZ, Wu ZH (2005) Ammonia-catalyzed hydrolysis kinetics of mixture of tetraethoxysilane with methyltriethoxysilane by 29Si NMR. J Non-Cryst Solids 351:2403–2413

Wu G, Wang J, Shen J, Yang T, Zhang Q, Zhou B, Deng Z, Fan B, Zhou D, Zhang F (2000) Novel route to control refractive index of sol–gel derived nano-porous silica films used as broadband antireflective coatings. Mater Sci Eng B 78:135–139

Yoldas BE, O’Keefe TW (1979) Antireflective coatings applied from metal–organic derived liquid precursors. Appl Opt 18:3133–3138

Menna P, DiFrancia G, LaFerrara V (1995) Porous silicon in solar cells: a review and a description of its application as an AR coating. Sol Energy Mater Sol Cells 37:13–24

SanVicente G, Bayon R, German N, Morales A (2009) Long-term durability of sol–gel porous coatings for solar glass cover. Thin Solid Films 517:3157–3160

ASTM D3363-00 (2000) Standard test method for film hardness by pencil test. ASTM International, West Conshohocken

Wang X, Shen J (2010) Sol–gel derived durable antireflective coating for solar glass. J Sol-Gel Sci Technol 53:322–327

Li X, Shen J (2011) A scratch-resistant and hydrophobic broadband antireflective coating by sol–gel method. Thin Solid Films 519:6236–6240

Chen CH, Li SY, Chiang AST, Wu AT, Sun YS (2011) Scratch resistant zeolite anti-reflective coating on glass for solar applications. Sol Energy Mater Sol Cells 95:1694–1700

Xu L, Geng Z, He J, Zhou G (2014) Mechanically robust, thermally stable, broadband antireflective, and superhydrophobic thin films on glass substrates. ACS Appl Mater Interfaces 6:9029–9035

Aytug T, Lupini AR, Jellison GE, Joshi PC, Ivanov IH, Liu T, Wang P, Menon R, Trejo RM, Curzio EL, Hunter SR, Simpson JT, Paranthamana MP, Christena DK (2015) Monolithic graded-refractive-index glass-based antireflective coatings: broadband/omnidirectional light harvesting and self-cleaning characteristics. J Mater Chem C 3:5440–5449

Xia B, Zhang Q, Yao S, Zhang Y, Xiao B, Jiang B (2014) Sol–gel silica antireflective coating with enhanced abrasion-resistance using polypropylene glycol as porogen. J Sol-Gel Sci Technol 71:291–296

Cai C, Yang X, Wang Z, Dong H, Ma H, Zhao N, Xu J (2015) Robust anti-reflective silica nanocoatings: abrasion resistance enhanced via capillary condensation of APTES. J Mater Chem C 3:4254–4259

Hwang DK, Moon JH, Shul YG, Jung KT, Kim DH, Lee DW (2003) Scratch resistant and transparent UV-protective coating on polycarbonate. J Sol-Gel Sci Technol 26:783–787

Gilberts J, Tinnemans AHA, Hogerheide MP, Koster TPM (1998) UV curable hard transparent hybrid coating materials on polycarbonate prepared by the sol–gel method. J Sol-Gel Sci Technol 11:153–159

Rahman P, Vejayakumaran CS, Sipaut J, Ismail CK (2008) Effect of the drying techniques on the morphology of silica nanoparticles synthesized via sol–gel process. Ceram Int 34:2059–2066

Fujishima A, Hashimoto K, Watanabe T (1999) TiO2 photocatalysis fundamentals and applications. BKC Inc, Arvada

Mills A, Lepre A, Elliott N, Bhopal S, Parkin IP, O’Neil SA (2003) Thick titanium dioxide films for semiconductor photocatalysis. J Photochem Photobiol A 160:185–194

Wang R, Hashimoto K, Fujishima A, Chikuni M, Kojima E, Kitamura A, Shimohigoshi M, Watanabe T (1997) Light-induced amphiphilic surfaces. Nature 388:431–432

Fujishima A, Kohayakawa K, Honda K (1975) Discussion of hydrogen production under sunlight with an electrochemical photocell. J Electrochem Soc 122:1487–1489

Tryk DA, Fujishima A, Honda K (2000) Recent topics in photoelectrochemistry: achievements and future prospects. Electrochim Acta 45:2363–3276

Sakthivel S, Kisch H (2003) Photocatalytic and photoelectrochemical properties of nitrogen-doped titanium dioxide. ChemPhysChem 4:487–490

Sakthivel S, Kisch H (2003) Daylight photocatalysis by carbon-modified titanium dioxide. Angew Chem Int Ed 42:4908–4911

Veith M, Peter O, Jilavi M, Sakthivel S (2011, 2012) DE 102009035797.1, WO 012214, US 0125234 and EP 2460035

Sakthivel S, Neppolian B, Shankar MV, Arabindoo B, Palanichamy M, Murugesan V (2003) Solar photocatalytic degradation of azo dye: comparison of photocatalytic efficiency of ZnO and TiO2. Sol Energy Mater Sol Cells 77:65–82

Acknowledgments

The authors are very grateful to Dr. G. Sundararajan, Director and Dr. S.V. Joshi, Additional Director of ARCI for providing all the necessary facilities and their great encouragement for this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Righeira Carnegie, M., Sherine, A., Sivagami, D. et al. Anti-reflection coatings with enhanced abrasion and scratch resistance properties. J Sol-Gel Sci Technol 78, 176–186 (2016). https://doi.org/10.1007/s10971-015-3924-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-015-3924-9