Abstract

Fe1−x Co x alloys were synthesized by sol–gel autocombustion method. The atomic ratios of Fe:Co were easily controlled by adjusting the relative concentration of Fe3+ and Co2+ in the preparation of the precursor gels. Their phases and compositions were confirmed by X-ray diffraction and energy-dispersive X-ray spectroscopy analysis. Morphology characterization revealed the porous structure with micron-size pores. Synthetic mechanism was studied by thermogravimetry and differential scanning calorimetry. Magnetic properties of the alloys were investigated at room temperature. The highest saturation magnetization was found to be about 231 emu/g, which is much larger than that of the corresponding alloys synthesized through other chemical methods.

Graphical Abstract

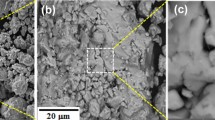

SEM images and magnetic hysteresis loop of Fe0.7Co0.3 alloy synthesized by sol–gel autocombustion method.

Similar content being viewed by others

References

Rong C, Zhang Y, Poudyal N, Xiong X, Kramer MJ, Liu JP (2010) Fabrication of bulk nanocomposite magnets via severe plastic deformation and warm compaction. Appl Phys Lett 96:102513-1–102513-3

Seo WS, Lee JH, Sun X, Suzukl Y, Mann D, Liu Z, Terashima M, Yang P, Mcconnell MV, Nishimura DG, Dai H (2006) FeCo/graphitic-shell nanocrystals as advanced magnetic-resonance-imaging and near-infrared agents. Nat Mater 5:971–976

Hutten A, Sudfeld D, Ennen I, Reiss G, Wojczykowski K, Jutzi PJ (2005) Ferromagnetic FeCo nanoparticles for biotechnology. Magn Magn Mater 293:93–101

Chaubey GS, Barcena C, Poudyal N, Rong C, Gao J, Sun S, Liu JP (2007) Synthesis and stabilization of FeCo nanoparticles. J Am Chem Soc 129:7214–7215

Kim JN, Kim JB, Kim JR, Kim KH (2013) Characterization of as-synthesized FeCo magnetic nanoparticles by coprecipitation method. J Appl Phys 113:17A313-1–17A313-3

Yan Q, Li S, Pang E, Wang Y (2014) Fabrication of hollow spheres FeCo alloy through a hydrothermal reduction method. Mater Lett 120:185–188

Zamanpour M, Chen Y, Hu B, Carroll K, Huba ZJ, Carpenter EE, Lewis LH, Harris VG (2012) Large-scale synthesis of high moment FeCo nanoparticles using modified polyol synthesis. J Appl Phys 111:07B528-1–07B528-3

Bouali HL, Bentayeb FZ, Louidi S, Guo X, Tria S, Sunol JJ, Escoda L (2013) X-ray line profile analysis of the ball-milled Fe–30Co alloy. Adv Powder Technol 24:168–174

Sirvent P, Berganza E, Aragon AM, Bollero A, Moure A, Garcia-Hernandez M, Marin P, Fernandez JF, Quesada A (2014) Effective high-energy ball milling in air of Fe65Co35 alloys. J Appl Phys 115:17B505-1–17B505-3

Shin SJ, Kim YH, Kim CW, Cha HG, Kim YJ, Kang YS (2007) Preparation of magnetic FeCo nanoparticles by coprecipitation route. Curr Appl Phys 7:404–408

Nguyen Q, Chinnasamy CN, Yoon SD, Sivasubramanian S, Sakai T, Baraskar A, Mukerjee S, Vittoria C, Harris VG (2010) Functionalization of FeCo alloy nanoparticles with highly dielectric amorphous oxide coatings. J Appl Phys 22:587–603

Poudyal N, Chaubey GS, Rong C, Cui J, Liu JP (2013) Synthesis of monodisperse FeCo nanoparticles by reductive salt-matrix annealing. Nanotechnology 24:345605-1–345605-6

Jiang YW, Yang SG, Hua ZH, Huang HB (2009) Sol–gel autocombustion synthesis of metals and metal alloys. Angew Chem Int Ed 48:8529–8531

Hua ZH, Deng Y, Li KN, Yang SG (2012) Low-density nanoporous iron foams synthesized by sol–gel autocombustion. Nanoscale Res Lett 7:1–7

Deshpande K, Mukasyan A, Varma A (2004) Direct synthesis of iron oxide nanopowders by the combustion approach: reaction mechanism and properties. Chem Mater 16:4896–4904

Denton AR, Ashcroft NW (1991) Vegard’s law. Phys Rev A 43:3161–3164

Chikazumi S (1964) Physics of magnetism. Wiley, New York, pp 72–77

Acknowledgments

This work was supported by National Natural Science Foundation of China under Grant No. 61176087.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, X., Hua, Z. & Yang, S. Sol–gel autocombustion synthesis and characterization of Fe1−x Co x alloys with large saturation magnetization. J Sol-Gel Sci Technol 78, 171–175 (2016). https://doi.org/10.1007/s10971-015-3909-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-015-3909-8