Abstract

Monodispersed porous ZnO nanospheres with diameters about 400–600 nm were successfully fabricated by a facile and effective cationic surfactant assisted selective etching strategy. The as-synthesized ZnO materials were characterized by X-ray diffraction, scanning electron microscope, transmission electron microscope and N2 adsorption–desorption. These samples were used as the gas sensor, showing the high, stable and fast response to acetone, revealing the potential application as gas sensor to detect acetone. In addition, the photocatalytic degradation property of the porous ZnO nanospheres for methyl orange (MO) under UV irradiation was investigated. The degradation efficiency of MO reaches 96 % of the porous ZnO samples after 50 min of UV-light irradiation.

Similar content being viewed by others

1 Introduction

Zinc oxide, a n-type semiconductor with a direct band gap (3.37 eV) and relatively high exciton binding energy (60 meV) at room temperature, has received much attention for catalysis, field-emission devices, optoelectronics, biomedicine and chemical sensors [1–8]. Beside the components, the structure, morphology, and particle size also were determined the performances of nanoparticles. So far, many workers tried to synthesize ZnO with various structures, such as nanobelts, nanorods, nanorings, hollow nanopheres, nanotubes and nanosheets [9–14] to satisfy the application needs. At present, many methods, such as sol–gel, thermal evaporation, precipitation and hydrothermal method [15–18], have been developed to prepare ZnO nanostructure with various structures. Gong et al. [19] reported utilizing a simple solution method synthesized spindle-like ZnO microcrystals at a low temperature condition and Jia et al. [20] reported a facile hydrothermal route for the production of ZnS/ZnO heterogeneous core–shell microspheres.

From the viewpoint of gas sensors and photocatalytic applications, porous ZnO materials are excellent candidates because of their special structure can usually provide a large surface-to-volume ratio which can greatly facilitate gas diffusion and mass transport in sensor material, thus improving the performance [21–25]. It is known that, the central nervous system of the human body is mainly restrained and narcotized by acetone. When acetone concentration is over 500 ppm, it can stimulate one’s nose, throat, liver and kidney even of making the person loss of consciousness, coma or death. Therefore, the detection of acetone is of great importance from the perspective of both environmental protection and human health [26–29]. Sahay et al. synthesized Zinc oxide thin film for detection of acetone, showing well sensitivity about 45 at 2,000 ppm [30]. Song et al. reported ZnO hollow spheres with 1.5 μm in size by one-pot hydrothermal reaction, showing 14 sensitivity at 1,000 ppm of acetone [31].

In this paper, porous ZnO nanospheres, with 400–600 nm in diameter, were synthesized by a cationic surfactant assisted selective etching strategy. It is a simple and possible way to improve the surface area of the ZnO nanoparticles (increase from 8.3 to 59.6 cm3 g−1). The pH value and surfactant concentration determine the porous structure of the final samples. Through HCl etching ZnO, the gas sensing and photocatalytic of porous ZnO is superior to reported pure ZnO [32, 33]. The gas sensing and photocatalytic degradation performances of these samples have been investigated in detail.

2 Experimental section

2.1 Materials

Cetyltrimethylammonium bromide (CTAB) was obtained from Aladdin. Zinc nitrate hexahydrate (Zn(NO3)2·6H2O), ammonium hydroxide, hydrochloric acid solution (HCl), and ethanol were purchased from Guangfu Industry of Fine Chemicals Institute, Tianjin. All the reagents were of analytical grade and used without further purification. Deionized water was used in all experiments.

2.2 Synthesis ZnO nanomaterials

Briefly, 1.19 g of Zn(NO3)2·6H2O was added to deionized water under vigorous stirring. Then, the solution was heated to 90 °C, and ammonium aqueous solution (3.15 mL) was added dropwise to the above solution. The mixture was continuously stirred until a white precipitate was formed. The products were centrifugally separated from the suspension and washed with deionized water and ethanol.

2.3 Synthesis of the porous ZnO nanomaterials

50 mg of the as-prepared ZnO nanospheres were homogeneously dispersed in 9 mL of deionized water by ultrasonication for 30 min, following the addition of 1 mL of CTAB aqueous solution (12.5 mg mL−1), then stirred at room temperature for 1 h, pH value of the solution reaches 6.35. After the mixture was stirred for 24 h at room temperature, the products were collected by centrifugation and washed with deionized water and ethanol. The products were calcined at 550 °C in air and maintained for 6 h in order to remove CTAB from the products. The sample was named as Z-CTAB-6.35. Without CTAB assisted etching, the sample was named Z-6.35. Z-CTAB-6.45 and Z-CTAB-6.25 means etching at pH = 6.45 and 6.25 with CTAB.

2.4 Photocatalytic tests

The photocatalytic performances of the sample were evaluated using methylorange (MO) as a model dye. A 500 W UV light-tube was used for the UV photodegradation test. In the test, an MO solution (20 mg L−1, 100 mL) and photocatalyst (50 mg) were placed in a beaker. The solution was continuously stirred for 60 min in the dark to ensure the establishment of an adsorption–desorption equilibrium among the heterostructured photocatalysts, MO and water. Then the suspension was placed under UV light irradiation. At the regular time intervals, a quantity of the suspension was taken and analyzed with a UV–vis absorption spectrometer.

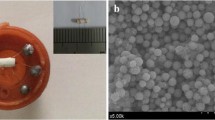

2.5 Sensor fabrication and gas-sensing property measurement

The as-synthesized sample was slightly mixed with deionized water to form the slurry. Then, the slurry was coated on a ceramic tube on which a pair of gold electrodes, and then a Ni–Cr heating wire was inserted in the tube to form a side-heated gas sensor.

Gas sensing properties were measured by using a static test system which included a test chamber and a data acquisition/processing system. Dry air was used as both a reference gas and a diluting gas to obtain desired concentrations of the target gases. The target gas was injected into the test chamber by a syringe through a rubber plug. When the response reached a constant value, the sensor was taken out to recover in dry air and the experiments were repeated. The gas response was defined as Ra/Rg, where Ra and Rg are the resistances of the sensor upon exposure to dry air and target gas, respectively. The response time was specified at the time to rise to 90 % of the equilibrium value of sensor resistance after the target gas was injected. The recovery time was defined as the time to decline to 10 % of the final resistance value after the removal of target gas. The operating current of the sensors was adjusted by varying a heating current. The operating current at 165 mA was used for all the samples in the follow experiments.

2.6 Characterization of the samples

The morphology of the products was recorded by scanning electron microscopy (SEM, Hitachi-4800) and transmission electron microscopy (TEM, JEOL 2010). X-ray powder difraction (XRD, Rigaku Dmax-2600/PC, CuKa radiation, λ = 0.1542 nm, 40 kV, 100 mA). The nitrogen adsorption/desorption, surface areas, and median pore diameters were measured by using a Quantachrome NOVA 2000 e analyzer. Before measuring at 77 K, the samples were degassed at 393 K for 12 h. Optical property was investigated by UV/Vis Spectrometer (Shimazu UV-2550).

3 Results and discussion

Figure 1 shows the SEM images of the sample. Figure 1a shows the as-synthesized ZnO nanomaterials possesses uniform ellipsoid morphology (400–600 nm in diameter). In order to clarify the morphological evolution of the porous ZnO materials, etching at different pH value was carried out. From Fig. 1b, Z-CTAB-6.45 shows the sphere morphology and the tips of ZnO nanoparticles becomes rounded when the pH value reaches 6.45 with CTAB protect. With the lower curvature radius, the two tips of the ZnO ellipsoids are dissolved easily. After etching, every ZnO ellipsoid was transferred to the ZnO sphere of all samples. Going on decreasing the pH value to 6.35, the materials also show the sphere morphology and the surface becomes rough and some porous structure can be seen obviously. Further decrease pH value to 6.25, Z-CTAB-6.25 was completely etched and the ZnO spheres were destroyed (Fig. 1d). However, without the protection of CTAB, ZnO sphere (Z-6.35) collapsed completely. From Fig. 1e, no intact sphere can be found. It is confirmed that CTAB can keep the morphology of ZnO nanospheres during the etching process, without CTAB ZnO particles can be dissolved. And the low pH value induces the drastically etching.

TEM images (Fig. 2) show the obvious different structure of these samples. From Fig. 2a, as-synthesized ZnO nanoparticles show the ellipsoid morphology. And there is obvious porous structure can be found from Fig. 2a. From Fig. 2b, Z-CTAB-6.35 shows the porous structure through the sphere. Without the CTAB protecting, the sample cannot remain the spherical morphology and porous structure also cannot be observed for Z–6.35 (Fig. 2c). From the high-resolution TEM image of Z-CTAB-6.3 (Fig. 2d), the spacing between two adjacent lattice planes is about 0.28 and 0.24 nm, ascribing to (100) and (101) planes of ZnO.

In this paper, CTAB was used as the protective-agent to remain the morphology of the sample, making the etching occur in the inner parts of the sphere. In aqueous solution, CTAB molecules assemble to form micelle and interact outside ZnO nano-particles to protect the morphology from further etched by H+. From above investigation, H+ prefers to enter inner and etching inner ZnO nanoparticles making porous structures at last.

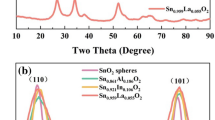

Figure 3 shows the XRD patterns of the as-prepared ZnO and Z-CTAB-6.35, respectively. The diffraction peaks of the all samples were in good agreement with hexagonal wurtzite ZnO structure (JCPDS file, No. 36-1451). No peaks from other structures are observed, indicating the high purity of the product. Comparing the XRD pattern of as-prepared ZnO with the Z-CTAB-6.35, the peak width of the Z-CTAB-6.35 is wider than that of as-prepared ZnO nanoparticles. It is the reason that the etching process making the particle sizes decrease and the peak width increase.

The nitrogen adsorption–desorption isotherms and pore size distribution of the samples are shown in Fig. 4. From the adsorption isotherm of as-synthesized ZnO, the adsorption loops are in the high relative pressure region. After etching the adsorption amount increase obviously due to the porous structure from etching. And that also can be reflected from the corresponding pore size distributions (Fig. 4b). From Fig. 4b, the as-prepared ZnO nanoparticles show no pore size distribution, and after etching the porous ZnO materials show pore distribution in 2–15 nm. And the surface area and pore volume also increase from 8.3 m2g−1 and 0.024 mLg−1 for as-prepared sample to 18.9 m2g−1 and 0.070 mLg−1, 59.6 m2g−1 and 0.213 mLg−1 for etching samples (pH = 6.45 and 6.35).

The FTIR spectra of ZnO nanosparticles (a), Z-CTAB-6.35 with CTAB protect (pH = 6.35) and without calcination (b) and after calcination Z-CTAB-6.35 (c) samples are shown in Fig. 5a–c. The broad at 478 cm−1 are attributed to the ZnO characteristic absorption peak. From Fig. 5a–c, the –OH stretching vibration and bending vibration at 3,400 and 1,640 cm−1 attributed to surface adsorbed H2O. The C–H (–CH2, –CH3) of CTAB stretching vibration peaks center at 2,921 and 2,850 cm−1 (Fig. 5b) Moreover, the peaks at 1,462 cm−1 is attributed to the NH2 characteristic absorption peak of CTAB. Above all when CTAB modified ZnO surface, the characteristic absorption peak of ZnO from 478 to 458 cm−1. It further gives a direct demonstration of CTAB in an etching process play a protection role which CTAB modified ZnO surface this peak was red-shifted from 458 cm−1 with significant diminution, and after calcination Z-CTAB-6.35, most of CTAB has removed (Fig. 5c).

To demonstrate photocatalytic activities of the as-synthesized porous ZnO nanospheres for the degradation of the organic pollutants, the experiments of the photocatalytic degradation of methyl orange (MO) have been carried out. Absorption spectra of photodegradation of MO dyes under UV irradiation are shown in Fig. 6. Figure 6a presents the absorption spectra of MO aqueous solution (initial concentration is 20 mg L−1) in the presence of the Z-CTAB-6.35 under exposure to UV light for different durations. The intensity of the absorbance peaks drops rapidly with the elongation of the exposure time and completely disappears 96.2 % after about 50 min. The absorption spectra of MO aqueous solution under the same condition with the Z-CTAB-6.45 and synthetic ZnO are shown in Fig. 6b, c. It revealed that the concentration of MO aqueous solution degraded 73 % during 80 min for Z-CTAB-6.45 and only 88 % of MO can be effectively decomposed by the synthetic ZnO after 100 min illumination.

Figure 6d reveals the photocatalytic degradation activity of MO using several different photocatalysts under the same condition. C0 and Ct are the initial concentration of MO after the equilibrium adsorption and that after the reaction, we compare two blank experiments, one is added as-synthesized ZnO, Z-CTAB-6.35 and Z-CTAB-6.45 in the dark condition, after 50 min, the degradation rates of MO reach 1.8, 7.9 and 3.8 % respectively. The other one in UV light irradiation without photocatalyst, the degradation rate of MO reaches 1.3 %. The as-synthesized ZnO and Z-CTAB-6.45 show about 55 and 61.7 % degradation in the MO solution after 50 min. As for the Z-CTAB-6.35, the degradation rate is 96.2 % after 50 min illumination, which is evidently greater than those of the above ZnO catalysts. This verifies the superior photoactivity of the Z-CTAB-6.35 compared with the synthetic ZnO and Z-CTAB-6.45. Hence, the order of the decomposition rate of the MO aqueous solution in the presence of above catalysts is as follows: Z-CTAB-6.35 (96.2 %) > Z-CTAB-6.45 (61.7 %) > synthetic ZnO (55 %).

The porous metal oxides are prospective material for gas sensor. The gas sensing properties of ZnO nanostructures have been widely investigated. However, the influence of ZnO morphology on the gas sensing performance has scarcely been investigated. Many studies have proven that some special structures could significantly affect the sensor performance. In addition, the surface accessibility and excellent channels were provided by the high porosity of the as-prepared porous architectures for the mass transportation of the target gases. In this paper, we studied the acetone and other gases sensing properties of porous ZnO nanospheres.

The sensitivity increases with the increase of operating current (Fig. 7). Until 165 mA, Z-CTAB-6.35 reveals the highest sensitivity (19.6). Further increasing operating current makes the sensitivity decrease. Therefore, in this paper, 165 mA was used as the operating current for all the experiments.

Figure 8 shows the variations of response of three sensors fabricated from pure ZnO and H+ etched ZnO to 50 ppm acetone at 165 mA. It is distinctly shown that, the response to Z-CTAB-6.35 (20) is higher than others, ascribing the largest surface area and pore volume of 59.6 m2g−1 and 0.213 mLg−1. That is beneficial for the transfer of the testing gas making the high response. Therefore, Z-CTAB-6.35 was chosen for the following research.

Figure 9 shows the responses of the sensor made from Z-CTAB-6.35 to various gases including CH3COCH3, C2H5OH, C6H5CH3, NO, CH3OH, SO2, NH3, H2, CO and H2S, where the operating current is 165 mA and the gas concentration is 50 ppm. It is clearly shown that, the response to CH3COCH3 (20) is almost 2 times larger than C2H5OH (11.5) and 3 times larger than to NO (7), the sensor displays the negligible response to SO2, NH3, H2, CO and H2S. These results show that the sensors based on the porous ZnO nanospheres exhibits considerable selectivity for CH3COCH3.

Figure 10 shows the response of Z-CTAB-6.35 to different concentrations of acetone and the response increases as the acetone concentration increases. For acetone concentrations at levels of 20, 50, 100, 500 and 1,000 ppm, the responses are about 19.6, 27.5, 41, 63.1 and 86.8, respectively. Furthermore, the response and recovery time were also discussed for the Z-CTAB-6.35 based sensors. The response and recovery times are quick at the sensitivity less than 10 ppm and the response time and recovery time are about 10 and 18 s (the inset), respectively for the sensor to 50 ppm acetone. Simultaneously, with the increase in acetone concentration, the response time has no obvious change, but recovery time decrease. The Z-CTAB-6.35 show the fastest response due to their porous structure, which facilitates the diffusion of gas molecules.

On the basis of the above results, the sensing mechanism of porous metal oxide based sensors can be explained as follows: It is well known that the surface-adsorbed oxygen plays an important role in the sensing process, because the conductivity of ZnO is mainly determined by the presence of singly charged oxygen vacancies.

The oxygen vacancies in porous ZnO nanospheres act as electron donors to provide electrons to the conduction band of porous ZnO nanospheres. When the ZnO sensors are encircled by air, oxygen molecules will be adsorbed on the sensor surface to produce negatively charged chemisorbed oxygen species, such as O2 −, O2−, or O−. Consequently, depletion layers are formed in the surface area of porous ZnO nanospheres, leading to the decline of carrier concentration and electron mobility, and making the conductivity decrease. When reducing gases are introduced, these reducing molecules may react with surface chemisorbed oxygen and release the trapped electron back to the conduction band, increasing of the carrier concentration and electron mobility, and resulting in the reducing of materials resistance.

Therefore, from the change of conductivity, the reducing gas can be sensed.

The related reactions are expressed as follows:

4 Conclusions

In summary, we have developed a facile etching route to fabricate porous ZnO. And, the photocatalytic degradation experiments revealed that the Z-CTAB-6.35 exhibit a high photocatalytic activity for the degradation of MO with a degradation rate of 96.2 % after 50 min, therefore these obtained porous ZnO nanospheres may be expected to have applications for eliminating organic pollutant in waste water. The gas-sensing showed that the Z-CTAB-6.35 has a high and fast response to acetone, gas sensor measurements were operated at the current of 165 mA with the concentration of 1,000 ppm, the sensor is sensitive to acetone with the response value of 86.8 demonstrating its excellent potential application as a gas sensor to detect acetone.

References

Singh G, Choudhary A, Haranath D, Joshi GA, Singh N, Singh S, Pasricha R (2012) Carbon 50:385–394

Yadav HK, Sreenivas K, Gupta V (2010) J Appl Phys 107:044507-1–044507-9

Meulenkamp EA (1998) J Phys Chem B 102:5566–5572

Hong YC, Tian G, Jiang BJ, Wu AP, Zhang Q, Tian GH, Fu HG (2013) J Mater Chem A 1:5700–5708

Fan S, Chaplie MG, Franklin NR, Tombler TW, Cassell AM, Dai H (1999) Science 283:512–514

Vispute RD, Talyansky V, Choopun S, Sharma RP (1998) Appl Phys Lett 73:348–350

Xiao X, Yuan LY, Zhong JW, Ding TP, Liu Y, Cai ZX, Rong YG, Han HW, Zhou J, Wang ZL (2011) Adv Mater 23:5440–5444

Bohle DS, Spina CJ (2007) J Am Chem Soc 129:12380–12381

Zhai QZ, Hu WH, Huang BL, Wang CY (2012) J Sol-Gel Sci Technol 63:435–444

Hames Y, Alpaslan Z, Kösemen A, San SE, Yerli Y (2010) Sol Energy 84:426–431

Hughes WL, Wang ZL (2004) J Am Chem Soc 126:6703–6709

Li ZQ, Xie Y, Xiong YJ, Zhang R (2003) New J Chem 10:1518–1521

Peng Y, Bao L (2008) Front Chem China 3:458–463

Wang J, Qu FY, Wu X (2013) Sci Adv Mater 5:1–8

Li W, Zhang F, Dou YQ, Wu ZX, Liu HJ, Qian XF, Gu D, Xia YY, Tu B, Zhao DY (2011) Adv Energy Mater 1:382–386

Bae SY, Na CW, Kang JH, Park J (2005) J Phys Chem B 109:2526–2531

Rodríguez-Paéz JE, Caballero AC, Villegas M, Moure C, Durán P, Fernández JF (2001) J Eur Ceram Soc 21:925–930

Ohshima E, Ogino H, Niikura I, Maeda K, Sato M, Ito M, Fukuda T (2004) J Cryst Growth 260:166–170

Gong LH, Wu X, Ye C, Qu FY (2010) J Alloy Compd 501:375–379

Jia WN, Jia BX, Lin HM, Qu FY, Wu X, Jiang JJ (2011) Micro Nano Lett 6:633–635

Cho S, Kim DH, Lee BS, Jung J, Yu WR, Hong SH, Lee S (2012) Sens Actuat B Chem 162:300–306

Chang HX, Sun ZH, Ho KYF, Tao XM, Yan F, Kwok WM, Zheng ZJ (2011) Nanoscale 3:258–264

Zhang J, Wang SR, Xu MJ, Wang Y, Zhu BL, Zhang SM, Huang WP, Wu SH (2009) Cryst Growth Des 9:3532–3537

Zeng Y, Zhang T, Yuan MX, Kang MH, Lu GY, Wang R (2009) Sensors Actuators B 143:93–98

Khan SB, Faisal M, Rahman MM, Jamal A (2011) Talanta 85:943–949

Li XB, Maa SY, Lia FM, Chen Y, Zhanga QQ, Yanga XH, Wanga CY, Zhu J (2013) Mater Lett 100:119–123

Liu L, Li SC, Zhuang J, Wang LY, Zhang JB, Li HY, Liu Z, Han Y, Jiang XX, Zhang P (2011) Sens Actuat B Chem 155:782–788

Sahay PP (2005) J Mater Sci 40:4383–4385

Song P, Wang Q, Yang ZX (2012) Mater Lett 86:168–170

Na CW, Woo HS, Kim ID, Lee JHS (2011) Chem Commun 47:5148–5150

Wei A, Pan LH, Huang W (2011) Mater Sci Eng B Solid 176:1409–1421

Qia Q, Zhang T, Liu L, Zheng XJ, Yu QJ, Zeng Y, Yang HB (2008) Sens Actuat B Chem 134:166–170

Mohajerani MS, Lak A, Simchi A (2009) J Alloy Compd 485:616–620

Acknowledgments

Financial support for this study was provided by the National Natural Science Foundation of China (21171045, 21101046), Natural Science Foundation of Heilongjiang Province of China (ZD201214, B201206), Program for Scientific and Technological Innovation team Construction in Universities of Heilongjiang province (2011TD010), Research Fund for the Doctoral Program of Higher Education of China (20102329110002), Pre-research Found for Technological Development of Harbin Normal University (12XYG-11).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiang, D., Qu, F., Chen, X. et al. Synthesis of porous ZnO nanospheres for gas sensor and photocatalysis. J Sol-Gel Sci Technol 69, 370–377 (2014). https://doi.org/10.1007/s10971-013-3229-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-013-3229-9