Abstract

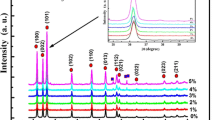

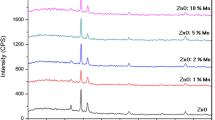

Nanocrystalline Zn1−xMnxS (x = 0.00, 0.01, 0.02, 0.03, 0.05, and 0.1) thin films having different Mn content were grown by the sol–gel dip coating process. The effect of Mn content on the structural, optical and magnetic properties of Zn1−xMnxS nanocrystalline thin films were investigated. X-ray diffraction results showed the presence of single hexagonal phase corresponding to ZnS with a preferred orientation along the ZnS (002) hexagonal plane direction without any detectable secondary phase, suggesting the incorporation of Mn ions into the ZnS lattice. Scanning electron microscope revealed the surface of the nanocrystalline films to be homogeneous and dense and the grains of the film surface were randomly scattered. In ultraviolet–visible measurements, the band gap energy corresponding to the absorption edge estimated were found to be 3.59–3.23 eV depending on the Mn doping ratio. Magnetic measurements showed that a paramagnetic behavior at 5 K and ferromagnetic behavior at 300 K.

Similar content being viewed by others

References

Dietl T, Ohno H, Matsukura F, Cibert J, Ferrand D (2000) Science 287:1019

Bartholomew DU, Furdyna JK, Ramdas AK (1986) Phys Rev B 34:6943

Hwang YH, Um YH, Furdyna JK (2004) Semicond Sci Technol 19:565–570

Deng H, Russell JJ, Lamb RN, Jiang B (2004) Thin Solid Films 458:43–46

Goktas A, Aslan F, Yasar E, Mutlu IH (2012) J Mater Sci Mater Electron 23:1361–1366

Parak WJ, Gerion D, Pellegrino T, Zanchet D, Micheel C, Williams SC, Boudreau R, Le Gros MA, Larabell CA, Alivisatos AP (2003) Nano Lett 3:33–36

Falcony C, Garcia M, Ortiz A, Alonso JC (1992) J Appl Phys 72:1525

Ding JX, Zapien JA, Chen WW, Lifshitz Y, Lee ST, Meng XM (2004) Appl Phys Lett 85:2361

Polat I, Aksu S, Altunbas M, Yılmaz S, Bacaksız E (2011) J Solid State Chem 184:2683–2689

Sambasivam S, Paul Joseph D, Raja Reddy D, Reddy BK, Jayasankar CK (2008) Mater Sci Eng B 150:125–129

Patel SP, Pivin JC, Patel MK, Won J, Chandra R, Kanjilal D, Kumar L (2012) J Magn Magn Mater 324:2136–2141

Cao J, Han D, Wanga B, Fan L, Fu H, Wei M, Feng B, Liu X, Yang J (2013) J Solid State Chem 200:317–322

Bol AA, Beek RV, Meijerink A (2002) Chem Mater 14:1121–1126

Awschalom DD, Kikkawa JM (1999) Phys Today 52(1999):33–38

Ni WS, Lin YJ, Liu CJ, Yang YW, Horng L (2013) J Alloy Compd 556:178–181

Geszke-Moritz M, Clavier G, Lulek J, Schneider R (2012) J Lumin 132:987–991

Sarkar I, Sanyal MK, Kar S, Biswas S, Banerjee S, Chaudhuri S, Takeyama S, Mino H, Komori F (2007) Phys Rev B 75:224409

Peng WQ, Qu SC, Cong GW, Zhang XQ, Wang ZG (2005) J Cryst Growth 282:179–185

Wang ZH, Geng DY, Li D, Zhan ZD (2007) J Mater Res 22:2376–2383

Tsujii N, Kitazawa H, Kido G (2003) J Appl Phys 93:6957

Zuo M, Tan S, Li GP, Zhang SY (2012) Science (China) 55:219–223

Yuan HJ, Yan XQ, Zhang ZX, Liu DF, Zhou ZP, Cao L, Wang JX, Gao Y, Song L, Liu LF, Zhao XW, Dou XY, Zhou WY, Xie SS (2004) J Cryst Growth 271:403–408

Lakshmi PVB, Sakthiraj K, Ramachandran K (2008) Cryst Res Technol 44:153–158

El-Hagary M, Soltan S (2013) Solid State Commun 155:29–33

Goktas A, Mutlu IH, Kawashi A (2012) Thin Solid Films 520:6138–6144

Goktas A, Mutlu IH, Yamada Y, Celik E (2013) J Alloy Compd 553:259–266

Goktas A, Mutlu IH, Yamada Y (2013) Superlatt Microstr 57:139–149

Goktas A, Aslan F, Mutlu IH (2012) J Mater Sci Mater Electron 23:605–611

Zarbali M, Göktaş A, Mutlu IH, Kazan S, Şale AG, Mikailzade F (2012) J Supercond Nov Magn 25:2767–2770

Dean JA (1999) Lange’s handbook of chemistry. McGRAW-Hill Inc, New York

El-Hagary M, Emam-Ismail M, Shaaban ER, Al-Rashidi A, Althoyaib S (2012) Mater Chem Phys 132:581–590

Cullity BD (1978) Elements of x-ray diffraction, 2nd edn. Addition-Weasley, London

Barreau N, Marsillac S, Bernede JC, Ben Nasrallah T, Belgacem S (2001) Phys Stat Sol A 184:179–186

Chauhan R, Kumar A, Chaudhary RP (2012) Chalcogenide Lett 9:151–156

Tauc J (1974) Amorphous and liquid semiconductor. Plenum, New York

Agbo SN, Ezema FI (2007) The Pacific J Sci Technol 8:150–154

Fan DB, Wang H, Zhang YC, Cheng J, Yan H (2007) Surf Rev Lett 11:27–31

Kanmani SS, Rajkumar N, Ramachandran K (2011) J Nano Electron Phys 3:1064–1070

Singh P, Kaushal A, Kaur D (2009) J Alloys Compd 471:11–15

Singhal S, Chawla AK, Gupta HO, Chandra R (2010) Nanoscale Res Lett 5:323–331

Ghosh PK, Ahmed SKF, Jana S, Chattopadhyay KK (2007) Opt Mater 29:1768–1772

Xu HY, Liu YC, Xu CS, Liu YX, Shao CL, Mu R (2006) J Chem Phys 124:074707

Elanchezhiyan J, Bhuvana KP, Gopalakrishnan N, Balasubramanian T (2008) Mater Lett 62:3379–3381

Chen W, Zhao LF, Wang YQ, Miao JH, Liu S, Xia ZC, Yuan SL (2005) Appl Phys Lett 87:042507

Ragam M, Sankar N, Ramachandran K (2011) Defect Diffus For 318:11–21

Kolesnik S, Dabrowski B (2004) J Appl Phys 96:5379

Delikanli S, He S, Qin Y, Zhang P, Zeng H, Zhang H, Swihart M (2008) Appl Phys Lett 93:132501

Bhattacharyya S, Estrin Y, Rich DH, Zitoun D, Koltypin Y, Gedanken A (2010) J Phys Chem C 114:22002–22011

Liu H, Zhang X, Li L, Wang YX, Gao KH, Li ZQ, Zheng RK, Ringer SP, Zhang B, Zhang XX (2007) Appl Phys Lett 91:072511

Quynh Hoa TT, Duc The N, McVitie S, Nam NH, Van Vu L, Canh TD, Long NN (2011) Opt Mater 33:308–314

Chen H, Shi D, Qi J (2011) J Appl Phys 109:084338

Saeed Y, Nazir S, Reshak AH, Shaukat A (2010) J Alloys Compd 508:245–250

Anderson PW (1950) Phys Rev 79:350

Xie J (2010) J Magn Magn Mater 322:L37–L41

Acknowledgments

This work was supported by the Higher Education Council of Turkey (YOK) and scientific and technological research council of Harran University (HUBAK) with project number 1029. The authors are grateful to Prof. Dr.Yasuji YAMADA Department of Physics and Materials, Interdisciplinary Faculty of Science and Engineering, Shimane University, Japan, for hosting and guiding of Abdullah GÖKTAŞ during his fellowship at Shimane University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Göktaş, A., Mutlu, İ.H. Room temperature ferromagnetism in Mn-doped ZnS nanocrystalline thin films grown by sol–gel dip coating process. J Sol-Gel Sci Technol 69, 120–129 (2014). https://doi.org/10.1007/s10971-013-3194-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-013-3194-3