Abstract

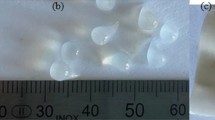

Layer-by-layer (LbL) alginate beads, which were prepared by multi-phase emulsion technique, had been fabricated via the ionic crosslinking between calcium ion (Ca2+) and the carboxylic group of alginate. The prepared beads were spherical, smooth-surfaced and non-aggregated. The SEM analysis displayed the LbL structure of the beads clearly. It had been demonstrated that the size of the beads was controllable and had a correlation with concentration of sodium alginate (SA) and CaCl2, ratio of water phase and oil phase (W/O), stirring speed, pH value of the water phase, viscosity of SA as well as the temperature for solidification. Stability studies showed that the beads degraded slowly in simulated gastric fluid and simulated intestinal fluid but degraded sharply when they were moved to simulated colonic fluid. Cytotoxicity study by MTT assay indicated that the prepared beads are slightly toxic. It is hoped that this kind of novel beads could be used in pharmaceutical area and cell culture area.

Similar content being viewed by others

References

Park JS, Lee CM, Lee KY (2007) A surface plasmon resonance biosensor for detecting Pseudomonas aeruginosa cells with self-assembled chitosan-alginate multilayers. Talanta 72:859–862

Ye SQ, Wang CY, Liu XX, Tong Z (2005) Deposition temperature effect on release rate of indomethacin microcrystals from microcapsules of layer-by-layer assembled chitosan and alginate multilayer films. J Controlled Release 106:319–328

Gaumann A, Laudes M, Jacob B, Pommersheim R, Laue C, Vogt W, Schrezenmeir J (2000) Effect of media composition on long-term in vitro stability of barium alginate and polyacrylic acid multilayer microcapsules. Biomaterials 21:1911–1917

Zhao QH, Han BS, Wang ZH, Gao CY, Peng CH, Shen JC (2007) Hollow chitosan-alginate multilayer microcapsules as drug delivery vehicle: doxorubicin loading and in vitro and in vivo studies. Nanomedicine 3:63–74

Jindarat W, Rattanadecho P, Vongpradubchai S (2011) Analysis of energy consumption in microwave and convective drying process of multi-layered porous material inside a rectangular wave guide. Exp Therm Fluid Sci 35:728–737

Roso M, Lorenzetti A, Besco S, Monti M, Berti G, Modesti M (2011) Application of empirical modelling in multi-layers membrane manufacturing. Comput Chem Eng 35:2248–2256

Zelikin AN, Li Q, Caruso F (2006) Degradable polyelectrolyte capsules filled with oligonucleotide sequences. Angew Chem Int Ed 45:7743–7745

Miao SD, Zhang CL, Liu ZM, Han BX, Xie Y, Ding SF, Yang ZZ (2008) Highly efficient nanocatalysts supported on hollow polymer nanospheres: synthesis, characterization, and applications. Phys Chem C 112:774–780

Ladet S, David L, Domard A (2008) Multi-membrane hydrogels. Nat Lett 452:76–79

de Villiers MM, Otto DP, Strydom SJ, Lvov YM (2011) Introduction to nanocoatings produced by layer-by-layer (LbL) self-assembly. Adv Drug Deliv Rev 63:701–715

Yang Y, He Q, Duan L, Cui Y, Li JB (2007) Assembled alginate/chitosan nanotubes for biological application. Biomaterials 28:3083–3090

Capela P, Hay TCK, Shah NP (2007) Effect of homogenisation on bead size and survival of encapsulated probiotic bacteria. Food Res Int 40:1261–1269

Kim IY, Seo SJ, Moon HS, Yoo MK, Park IY, Kim BC, Cho CS (2008) Chitosan and its derivatives for tissue engineering applications. Biotechnol Adv 26:1–21

Shi GQ, Chen YW, Wan CX, Yu XX, Feng T, Ding YL (2008) Study on the preparation of chitosan–alginate complex membrane and the effects on adhesion and activation of endothelial cells. Appl Surf Sci 255:422–425

Li Z, Ramay HR, Hauch KD, Xiao D, Zhang M (2005) Chitosan–alginate hybrid scaffolds for bone tissue engineering. Biomaterials 26:3919–3928

Johnson FA, Craig DQM, Mercer AD (1997) Characterization of the block structure and molecular weight of sodium alginates. J Pharm Pharmacol 49:639–643

Liu XX, Qian LY, Shu T, Tong Z (2003) Rheology characterization of sol–gel transition in aqueous alginate solutions induced by calcium cations through in situ release. Polymer 44:407–412

Gacesa P (1988) Alginates. Carbohydr Polym 8:161–182

Smidsrod O, Skjakbraek G (1990) Alginate as immobilization matrix for cells. Trends Biotechnol 8:71–78

Kolambkar YM, Dupont KM, Boerkcel JD, Hutmacher DW, Guldberg RE (2010) An alginate-based hybrid system for growth factor delivery in the functional repair of large bone defects. Biomaterials 32:65–74

Kim MH, Kim JC, Lee HY, Kim JD, Yang JH (2005) Release property of temperature-sensitive alginate beads containing poly (N-isopropylacrylamide). Coll Surf B Biointerfaces 46:57–61

Levy FE, Levy MC (1999) Serum albumin–alginate coated beads: mechanical properties and stability. Biomaterials 20:2069–2084

Stabler C, Wilks K, Sambanis A, Constantinidis I (2001) The effects of alginate composition on encapsulated βTC3 cells. Biomaterials 22:1301–1310

Zhang J, Chen XG, Sun GZ, Huang L, Cheng XJ (2010) Effect of molecular weight on the oleoyl-chitoan nanoparticles as carriers for doxorubicin. Colloids Surf B Biointerfaces 77:125–130

Jorgensen L, Moeller EH, van de Weert M, Nielsen HM, Frokjaer S (2006) Preparing and evaluating delivery systems for proteins. Eur J Pharm Sci 29:174–182

Castellanos IJ, Cruz G, Crespo R, Griebenow K (2002) Encapsulation-induced aggregation and loss in activity of -chymotrypsin and their prevention. J Control Release 81:307–319

Coombes AGA, Yeh MK, Lavelle EC, Davis SS (1998) The control of protein release from poly (dl-lactide co-glycolide) microparticles by variation of the external aqueous phase surfactant in the water-in oil-in water method. J Control Release 52:311–320

Freitas S, Merkle HP, Gander B (2005) Microencapsulation by solvent extraction/evaporation: reviewing the state of the art of microsphere preparation process technology. J Control Release 102:313–332

Kim JH, Bae YH (2004) Albumin loaded microsphere of amphiphilicpoly (ethylene glycol)/aliphaticpoly (ester) multiblock copolymer. Eur J Pharm Sci 23:245–251

Takada S, Yamagata Y, Misaki M, Taira K, Kurokawa T (2003) Sustained release of human growth hormone from microcapsules prepared by a solvent evaporation technique. J Control Release 88:229–242

Lu W, Park TG (1995) Protein release from poly (lactic-co-glycolic acid) microspheres: protein stability problems. PDA J Pharm Sci Tech 49:13–19

Park TG, Lee HY, Nam YS (1998) A new preparation method for protein loaded poly (d, l-lactic-co-glycolic acid) microspheres and protein release mechanism study. J Control Release 55:181–191

Zhao QS, Ji QX, Cheng XJ, Sun GZ, Zhao B, Chen XG (2010) Preparation of alginate coated chitosan hydrogel beads by thermosensitive internal gelation technique. J Sol-Gel Sci Technol 54:232–237

Anal AK, Stevens WF (2005) Chitosan–alginate multilayer beads for controlled release of ampicillin. Int J Pharm 290:45–54

Zhao QS, Cheng XJ, Ji QX, Kang CZ, Chen XG (2009) Effect of organic and inorganic acids on chitosan/glycerophosphate thermosensitive hydrogel. J Sol-Gel Sci Technol 50:111–118

Tavakol M, Farahani EV, Farahani TD, Najafabadi SH (2009) Sulfasalazine release from alginate-N, O-carboxymethyl chitosan gel beads coated by chitosan. Carbohydr Polym 77:326–330

Sun W, Griffiths MW (2000) Survival of bifidobacteria in yogurt and simulated gastric juice following immobilization in gellan–xanthan beads. Int J Food Microbiol 61:17–25

Liu LS, Liu SQ, Ng SY, Froix M, Ohno T, Heller J (1997) Controlled release of interleukin-2 for tumour immunotherapy using alginate/chitosan porous microspheres. J Control Release 43:65–74

Dainty AL, Goulding KH, Robinson PK, Simpkins I, Trevan MD (1986) Stability of alginate immobilized algal cells. Biotechnol Bioeng 28:210–216

Li Y, Hu M, Du YM, Xiao H, McClements DJ (2011) Control of lipase digestibility of emulsified lipids by encapsulation within calcium alginate beads. Food Hydrocoll 25:122–130

Acknowledgments

This work was supported by grants from the National Natural Science Foundation of China (NSFC,81071274), International S&T Cooperation Program of China (ISTCP,2011DFA31270).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, Y., Kong, M., Feng, C. et al. Preparation and property of layer-by-layer alginate hydrogel beads based on multi-phase emulsion technique. J Sol-Gel Sci Technol 62, 217–226 (2012). https://doi.org/10.1007/s10971-012-2712-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-012-2712-z