Abstract

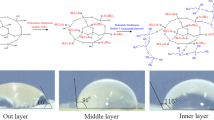

The experimental results of thermal process on the microstructural and physical properties of ambient pressure dried hydrophobic silica aerogel monoliths are reported and discussed. With sodium silicate as precursor, ethanol/hexamethyldisiloxane/hydrochloric acid as surface modification agent, the crack-free and high hydrophobic silica aerogel monoliths was obtained possessing the properties as low density (0.096 g/cm3), high surface area (651 m2/g), high hydrophobicity (~147°) and low thermal conductivity (0.0217 Wm/K). Silica aerogels maintained hydrophobic behavior up to 430 °C. After a thermal process changing from room temperature to 300 °C, the hydrophobicity remained unchanged (~128°), of which the porosity was 95.69% and specific density about 0.094 g/cm3. After high temperature treatment (300–500 °C), the density of final product decreased from 0.094 to 0.089 g/cm3 and porosity increased to 96.33%. With surface area of 466 m2/g, porosity of 91.21% and density about 0.113 g/cm3, silica aerogels were at a good state at 800 °C. Thermal conductivities at desired temperatures were analyzed by the transient plane heat source method. Thermal conductivity coefficients of silica aerogel monoliths changed from 0.0217 to 0.0981 Wm/K as temperature increased to 800 °C, revealed an excellent heat insulation effect during thermal process.

Similar content being viewed by others

References

Hrubesh LW (1990) J Chem Ind 824:17

Bhagat SD, Kim YH, Ahn YS, Yeo JG (2007) Appl Surf Sci 253:3231

Reim M, Korner W, Manara J, Korder S, Arduini-Schuster M, Ebert HP (2005) J Fricke Solar Energy 79:131

Smirnova S, Suttiruengwong AW (2004) J Non-Cryst Solids 350:54

Pajonk GM (1991) J Appl Catal 72:217

Hrubesh LW, Coronado PR, Satcher JH Jr (2001) J Non-Cryst Solids 285:328

Akimov YK (2003) R Instrum Exp Tech 46:287

Carlson G, Lewis D, McKinley K, Richardson J, Tilloston T (1995) J Non-Cryst Solids 186:372

Hüsing N, Schubert U (1998) J Angew Chem Int Ed 37:22

Schwertfeger F, Frank D, Schmidt M (1998) J Non-Cryst Solids 225:24

Schmidt M, Schwertfeger F (1998) J Non-Cryst Solids 225:364

Kim GS, Hyun SH (2003) J Mater Sci 38:1961

Rao AP, Pajonk GM, Rao AV (2005) J Mater Sci 40:3481

Rao AV, Rao AP, Kulkarni MM (2004) J Non-Cryst Solids 350:224

Rao AP, Rao AV, Pajonk GM (2007) J Appl Surf Sci 253:6032

Reichenauer G, Scherer GW (2001) J Colloid Interf Sci 236:385

Bi Z, Zhang Z, Xu F, Qian YY (1999) J Colloid Interf Sci 214:368

Bikerman JJ (1958) Surface Chemistry: Theory and Applications, 2nd edn. Academic Press, New York, p 343

Wang LJ, Zhao SY, Yang M (2009) J Mater Chem Phys 113:485

Rao AV, Kalesh R, Amalnerkar DP, Seth T (2003) J Porous Mater 10:23

Rassy HE, Pierre AC (2005) J Non-Cryst Solids 351:1603

Zhou XC, Zhong LP, Xu YP (2008) J Inorg Mater 44:976

Bhagat SD, Kim YH, Yi GB, Ahn YS, Yeo JG (2006) J Micropor Mesopor Mater 253:3231

Deshpande R, Smith DM, Brinker CJ (1992) J Non-Cryst Solids 144:32

Lee S, Chad YC, Hwang HJ, Hwang HJ, Moon JW, Han IS (2007) J Mater Lett 61:3130

Suh DJ, Park TJ, Sonn JH, Lim JC (1999) J Mater Sci Lett 18:1473

Sarawade PB, Kim JK, Hilonga A, Kim HT (2010) Korean J Chem Eng 27(4):1301

Burns GT, Deng Q, Field R, Hahn JM, Lengtz CW (1999) J Chem Mater 11:1275

Pierre AC, Elaloui E, Pajonk GM (1998) J Langmuir 14:66

Li WC, Lu AH, Guo SC (2002) J Colloid Interface Sci 254:153

Sing KSW, Everett DH, Haul RW, Moscou L, Pierotti RA, Rouquerol J, Siemieniewska T (1985) J Pure Appl Chem 57:603

Acknowledgments

This work was supported by National Natural Science Foundation of China (50802064, 51072137, and 11074189), New Century Excellent Talents in University of China (NCET-08-0405), National Science and Technology Support Program (2009BAC62B02).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, G., Zhou, B., Ni, X. et al. Influence of thermal process on microstructural and physical properties of ambient pressure dried hydrophobic silica aerogel monoliths. J Sol-Gel Sci Technol 62, 126–133 (2012). https://doi.org/10.1007/s10971-012-2694-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-012-2694-x