Abstract

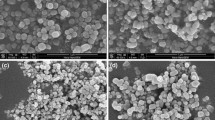

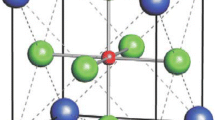

In this paper, a novel nanoporous barium titanate (BaTiO3) crystalline powder was synthesized by using triblock poly(ethylene oxide) (PEO) and poly(propylene oxide) (PPO) based systems (P-123) as the soft template via a sol–gel method and their structure-dependent electro rheological property was studied. The pore diameter and specific surface area of BaTiO3 were precisely controlled by varing the calcined temperature. The chemical composition, structure and surface morphology of BaTiO3 were characterized by X-ray diffraction (XRD), thermo gravimetric analysis (TGA), and nitrogen adsorption–desorption method, scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The result revealed that the pore volume and specific surface area of BaTiO3 decreased with the increment of calcined temperature. The electro rheological fluids (ERFs) were obtained by dispersing BaTiO3 crystallites in silicon oil and three kinds ERFs were fabricated by using three kinds of BaTiO3 which were prepared under different calcined temperature (550, 600 and 900 °C) as the precursors. The behaviors of the ERFs were evaluated via a rotational rheometer fixed with electric field generator. The results showed that electro rheological effect was related to the pore volume and specific surface area of BaTiO3. Due to the distinct advantage of sol–gel method for preparing nanoporous BaTiO3 without contamination of the materials, the markedly low current destiny of the ERFs was obtained. The yield stress of ERFs with large specific surface area of BaTiO3 reached the maximum of 3 kPa, which is higher than that of ERFs using traditional pure BaTiO3 crystallites (lower than 1 kPa).

Similar content being viewed by others

References

Satoshi O, Akira K, Hirofumi S, Kazuyoshi S, Hiroya A, Makio N (2008) Mater Lett 62:2957. doi:10.1016/j.matlet.2008.01.083

Fang CY, Wang CP, Polotai AV, Agrawal DK, Lanagan MT (2008) Mater Lett 62:2551. doi:10.1016/j.matlet.2007.12.045

Cui B, Yu PF, Wang X (2008) J Alloy Comp 459:589. doi:10.1016/j.jallcom.2007.07.039

Chen YY, Yu BY, Wang JH, Cochran RE, Shyue JJ (2009) Inorg Chem 48:681. doi:10.1021/ic8018887

Zhang SY, Jiang FS, Qu G, Lin CY (2008) Mater Lett 62:2225. doi:10.1016/j.matlet.2007.11.055

Wang ZY, Hu J, Yu MF (2006) Appl Phys Lett 89:263119. doi:10.1063/1.2425047

Yuh JH, Nino JC, Sigmund WM (2005) Mater Lett 59:3645. doi:10.1016/j.matlet.2005.07.008

Larsen G, Lotero E, Nabity M, Petkovic LM, Shobe DS (1996) J Catal 164:246. doi:10.1006/jcat.1996.0379

Victor F, Stone J, Davis RJ (1998) Chem Mater 10:1468. doi:10.1021/cm980050r

Corma A (1997) Chem Rev 97:2373. doi:10.1021/cr960406n

Zheng MB, Cao J, Liao ST, Liu JS, Chen HQ, Zhao Y, Dai WJ, Ji GB, Cao JM, Tao J (2009) J Phys Chem C 113:3887. doi:10.1021/jp810230d

Li YF, Li HF, Li TH, Li GL, Cao R (2009) Microporous Mesoporous Mater 117:444. doi:10.1016/j.micromeso.2008.06.042

Li H, Ni YH, Cai YF, Zhang L, Zhou JZ, Hong JM, Wei XW (2009) J Mater Chem 19:594. doi:10.1039/b818574c

Moreira ML, Mambrini GP, Volanti DP, Leite ER, Orlandi MO, Pizani PS, Mastelaro VR, Paiva-Santos CO, Longo E, Varela JA (2008) Chem Mater 20:5381. doi:10.1021/cm801638d

Orhan E, Varela JA (2005) Phys Rev B 71:085113. doi:10.1103/PhysRevB.71.085113

Wang YG, Xu G, Yang LL, Ren ZH, Wei X, Weng WJ, Du PY, Shen G, Han GR (2009) Mater Lett 63:239. doi:10.1016/j.matlet.2008.09.050

Wu ZB, Yoshimura M (1999) Solid State Ion 122:161. doi:10.1016/S0167-2738(99)00030-2

Yamauchi Y, Kuroda K (2008) Chem Asian J 3:664. doi:10.1002/asia.200700350

Hou RZ, Ferreira P, Vilarinho PM (2008) Microporous Mesoporous Mater 110:392. doi:10.1016/j.micromeso.2007.06.051

Zhang J, Ma YB, Shi F, Liu LQ, Deng YQ (2009) Microporous Mesoporous Mater 119:97. doi:10.1016/j.micromeso.2008.10.003

Sun ZX, Zheng TT, Bo QB, Vaughan D, Warren M (2008) J Mater Chem 18:5941. doi:10.1039/b810202c

Lia LX, Zou LD, Song HH, Morris G (2009) Carbon 47:775. doi:10.1016/j.carbon.2008.11.012

Tsai MC, Chang JC, Sheu HS, Chiu HT, Lee CY (2009) Chem Mater 21:499. doi:10.1021/cm802327z

Lee B, Yamashita T, Lu DL, Kondo JN, Domen K (2002) Chem Mater 14:867. doi:10.1021/cm010775m

Block H, Kelly JP (1988) J Phys D Appl Phys 21:1661. doi:10.1088/0022-3727/21/12/001

Wei JH, Zhao LH, Peng SL, Shi J, Liu ZY, Wen WJ (2008) J Sol–Gel Sci Technol 47:311. doi:10.1007/s10971-008-1787-z

Gong XQ, Wu JB, Huang XX, Wen WJ, Sheng P (2008) Nanotechnology 19:165

Lopes KP, Cavalcante LS, Simões AZ, Varela JA, Longo E, Leite ER (2009) J Alloy Comp 468:327. doi:10.1016/j.jallcom.2007.12.085

Yu PF, Cui B, Shi QZ (2008) Mater Sci Eng A 473:34. doi:10.1016/j.msea.2007.03.051

Yin JB, Zhao XP (2002) Chem Mater 14:4633. doi:10.1021/cm020388s

Cui B, Yu PF, Wang X (2008) J Alloy Comp 459:589. doi:10.1016/j.jallcom.2007.07.039

Marques VS, Cavalcante LS, Sczancoski JC, Volanti DP, Espinosa JWM, Joya MR, Santos MRMC, Pizani PS, Varela JA, Longo E (2008) Solid State Sci 10:1056. doi:10.1016/j.solidstatesciences.2007.11.004

Nunes MGB, Cavalcante LS, Santos V, Sczancoski JC, Santos MRMC, Santos-Júnior LS, Longo E (2008) J Sol–Gel Sci Technol 47:38. doi:10.1007/s10971-008-1751-y

Wang BX, Zhao Y, Zhao XP (2007) Colloids Surf A Physicochem Eng Asp 295:27. doi:10.1016/j.colsurfa.2006.08.025

Kim SG, Kim JW, Jang WH, Choi HJ, Jhon MS (2001) Polymer (Guildf) 42:5005. doi:10.1016/S0032-3861(00)00887-9

Klingenberg DJ, Vanswol F, Zuoski CF (1991) J Chem Phys 94:6170. doi:10.1063/1.460403

Acknowledgments

Financial support from National Basic Research Program of China (973 Program, Grant No. 2007CB936800) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Jiang, W., Jiang, C., Gong, X. et al. Structure and electrorheological properties of nanoporous BaTiO3 crystalline powders prepared by sol–gel method. J Sol-Gel Sci Technol 52, 8–14 (2009). https://doi.org/10.1007/s10971-009-2011-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-009-2011-5