Abstract

A solid-phase metallurgy combined with spark plasma sintering technology was used to prepare U3Si2 pellets. The thermal conductivity and oxidation behavior of the pellets were studied. The pellets were highly dense (> 98% theoretical density) and had an ultra-high phase purity. The thermal conductivity of the U3Si2 pellets increased linearly with temperature from 300 to 973 K. By further annealing the pellets at 300 °C in air for two hours, the oxidation onset temperature was increased from 490 to 520 °C. A mechanism of pore passivation was proposed to account for the enhanced oxidation resistance.

Similar content being viewed by others

References

Scapin MA, Salvador VLR, Cotrim MEB, Pires MAF, Sato IM (2010) Uncertainty measurement evaluation of WDXRF and EDXRF techniques for the Si and Utotal determination in U3Si2 nuclear fuel. J Radioanal Nucl Chem 287:807–811. https://doi.org/10.1007/s10967-010-0897-6

Poineau F, Yeamans CB, Silva GWC, Cerefice GS, Sattelberger AP, Czerwinski KR (2011) X-ray absorption fine structure spectroscopic study of uranium nitrides. J Radioanal Nucl Chem 292:989–994. https://doi.org/10.1007/s10967-011-1551-7

Scapin MA, Silva CP, Cotrim MEB, Pires MAF (2014) Application of multivariate calibration for simultaneous determination of major and minor constituents in U3Si2 by WDXRF technique. J Radioanal Nucl Chem 302:1077–1085. https://doi.org/10.1007/s10967-014-3332-6

Ekberg C, Ribeiro Costa D, Hedberg M, Jolkkonen M (2018) Nitride fuel for Gen IV nuclear power systems. J Radioanal Nucl Chem 318:1713–1725. https://doi.org/10.1007/s10967-018-6316-0

Jayabun S, Pathak S, Rajeswari B, Bhoir S, Sengupta A (2022) ICP-OES based methodology for determination of critical elements in U3Si2 matrix. J Radioanal Nucl Chem 331:2117–2123. https://doi.org/10.1007/s10967-022-08275-4

Carmack J, Goldner, Frank. (2013) Overview of the U.S. DOE accident tolerant fuel development program. United States: N p. https://www.osti.gov/servlets/purl/1130553.

Zinkle SJ, Terrani KA, Gehin JC, Ott LJ, Snead LL (2014) Accident tolerant fuels for LWRs: a perspective. J Nucl Mater 448:374–379. https://doi.org/10.1016/j.jnucmat.2013.12.005

Johnson KD, Raftery AM, Lopes DA, Wallenius J (2016) Fabrication and microstructural analysis of UN-U3Si2 composites for accident tolerant fuel applications. J Nucl Mater 477:18–23. https://doi.org/10.1016/j.jnucmat.2016.05.004

Chen S, Ge Y, Zhong Y, Yuan C (2020) Radial distributions of power and fuel temperature in annular U3Si2 fuel with FeCrAl cladding. Ann Nucl Sci Tech. https://doi.org/10.1016/j.anucene.2019.106943

Karoutas Z, Brown J, Atwood A, Hallstadius L, Lahoda E, Ray S, Bradfute J (2018) The maturing of nuclear fuel: past to accident tolerant fuel. Prog Nucl Energy 102:68–78. https://doi.org/10.1016/j.pnucene.2017.07.016

Zhou W, Zhou W (2018) Enhanced thermal conductivity accident tolerant fuels for improved reactor safety—a comprehensive review. Ann Nucl Sci Tech 119:66–86. https://doi.org/10.1016/j.anucene.2018.04.040

Gong B, Yao T, Lei P, Cai L, Metzger KE, Lahoda EJ, Boylan FA, Mohamad A, Harp J, Nelson AT, Lian J (2020) U3Si2 and UO2 composites densified by spark plasma sintering for accident-tolerant fuels. J Nucl Mater. https://doi.org/10.1016/j.jnucmat.2020.152147

Marín J, Lisboa J, Ureta J, Olivares L, Contreras H, Chávez JC (1996) Synthesis and clad interaction study of U3Si2 powders dispersed in an aluminum matrix. J Nucl Mater 228:61–67. https://doi.org/10.1016/0022-3115(95)00167-0

Saliba-Silva AM, Durazzo M, de Carvalho EFU, Riella HG (2008) Fabrication of U3Si2 powder for fuels used in IEA-R1 nuclear research reactor. Mater Sci Forum 591–593:194–199. https://doi.org/10.4028/www.scientific.net/MSF.591-593.194

Harp JM, Lessing PA, Hoggan RE (2015) Uranium silicide pellet fabrication by powder metallurgy for accident tolerant fuel evaluation and irradiation. J Nucl Mater 466:728–738. https://doi.org/10.1016/j.jnucmat.2015.06.027

White JT, Nelson AT, Dunwoody JT, Byler DD, Safarik DJ, McClellan KJ (2015) Thermophysical properties of U3Si2 to 1773 K. J Nucl Mater 464:275–280. https://doi.org/10.1016/j.jnucmat.2015.04.031

Lopes DA, Benarosch A, Middleburgh S, Johnson KD (2017) Spark plasma sintering and microstructural analysis of pure and Mo doped U3Si2 pellets. J Nucl Mater 496:234–241. https://doi.org/10.1016/j.jnucmat.2017.09.037

Mohamad A, Ohishi Y, Muta H, Kurosaki K, Yamanaka S (2018) Thermal and mechanical properties of polycrystalline U3Si2 synthesized by spark plasma sintering. J Nucl Sci Technol 55:1141–1150. https://doi.org/10.1080/00223131.2018.1480431

Gong B, Yao T, Lei P, Harp J, Nelson AT, Lian J (2020) Spark plasma sintering (SPS) densified U3Si2 pellets: microstructure control and enhanced mechanical and oxidation properties. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2020.154022

Havette J, Iltis X, Palancher H, Drouan D, Fiquet O, Castelier E, Pasturel M (2020) From arc-melted ingot to MTR fuel plate: a SEM/EBSD microstructural study of U3Si2. J Nucl Mater. https://doi.org/10.1016/j.jnucmat.2020.152224

Buckley J, Goddard DT, Abram TJ (2021) Studies on the spark plasma sintering of U3Si2: processing parameters and interactions. J Nucl Mater. https://doi.org/10.1016/j.jnucmat.2020.152655

Sooby Wood E, White JT, Nelson AT (2017) Oxidation behavior of U-Si compounds in air from 25 to 1000 ℃. J Nucl Mater 484:245–257. https://doi.org/10.1016/j.jnucmat.2016.12.016

Fink JK (2000) Thermophysical properties of uranium dioxide. J J Nucl Mater 279:1–18. https://doi.org/10.1016/s0022-3115(99)00273-1

Hoggan RE, Tolman KR, Cappia F, Wagner AR, Harp JM (2018) Grain size and phase purity characterization of U3Si2 fuel pellets. J Nucl Mater 512:199–213. https://doi.org/10.1016/j.jnucmat.2018.10.011

Antonio DJ, Shrestha K, Harp JM, Adkins CA, Zhang Y, Carmack J, Gofryk K (2018) Thermal and transport properties of U3Si2. J Nucl Mater 508:154–158. https://doi.org/10.1016/j.jnucmat.2018.05.036

Ranasinghe JI, Jossou E, Malakkal L, Szpunar B, Szpunar JA (2018) Study on radial temperature distribution of aluminum dispersed nuclear fuels: U3O8-Al, U3Si2-Al, and UN-Al. J Nucl Eng Radiat Sci. https://doi.org/10.1115/1.4039886

Kaloni TP, Torres E (2020) Thermal and mechanical properties of U3Si2: a combined ab-initio and molecular dynamics study. J Nucl Mater. https://doi.org/10.1016/j.jnucmat.2020.152090

Khalfa M, Hadji S, Korichi S, Boucherit H, Khachai H, Khenata R, Rahal B, Sahli A, Bin Omran S (2022) High pressure and temperature dependence of the structural, electronic, thermal and transport properties of U3Si2: computational insights. Phys Status Solidi B. https://doi.org/10.1002/pssb.202100630

White JT, Nelson AT, Byler DD, Safarik DJ, Dunwoody JT, McClellan KJ (2015) Thermophysical properties of U3Si5 to 1773 K. J Nucl Mater 456:442–448. https://doi.org/10.1016/j.jnucmat.2014.10.021

Milena-Pérez A, Rodríguez-Villagra N, Fernández-Carretero S, Núñez A (2023) Thermal air oxidation of UO2: joint effect of precursor’s nature and particle size distribution. Prog Nucl Energy. https://doi.org/10.1016/j.pnucene.2023.104629

Gong B, Cai L, Lei P, Metzger KE, Lahoda EJ, Boylan FA, Yang K, Fay J, Harp J, Lian J (2020) Cr-doped U3Si2 composite fuels under steam corrosion. Corros Sci. https://doi.org/10.1016/j.corsci.2020.109001

Turner J, Abram T (2020) Steam performance of UB2/U3Si2 composite fuel pellets, compared to U3Si2 reference behaviour. J Nucl Mater. https://doi.org/10.1016/j.jnucmat.2019.151919

Mohamad A, Yao T, Gong B, Harp J, Wagner AR, Nelson AT, Lian J (2021) Aluminum-doped U3Si2 composite fuels with enhanced oxidation resistance. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2020.157319

Mohamad A, Gong B, Yao T, Wagner AR, Benson MT, Lian J (2021) 3Y-TZP toughened and oxidation-resistant U3Si2 composites for accident tolerant fuels. J Nucl Mater. https://doi.org/10.1016/j.jnucmat.2020.152691

Schwarz JA, Contescu C, Contescu A (2002) Methods for preparation of catalytic materials. Chem Rev 95:477–510. https://doi.org/10.1021/cr00035a002

Ye W, Zhao C, Shen X, Ma C, Deng Z, Li Y, Wang Y, Zuo C, Wen Z, Li Y, Yuan X, Wang C, Cao Y (2021) High quantum yield Gd4.67Si3O13:Eu3+ red-emitting phosphor for tunable white light-emitting devices driven by UV or blue LED. ACS Appl Electron Mater 3:1403–1412. https://doi.org/10.1021/acsaelm.1c00012

Chuev II, Kovalev DY (2022) Effects of titanium high energy ball milling on the solid-phase reaction Ti+C. Mater Chem Phys. https://doi.org/10.1016/j.matchemphys.2022.126025

Toby BH (2001) EXPGUI, a graphical user interface for GSAS. J Appl Crystallogr 34:210–213. https://doi.org/10.1107/s0021889801002242

Mendelson MI (1969) Average grain size in polycrystalline ceramics. J Am Ceram Soc 52:443–446. https://doi.org/10.1111/j.1151-2916.1969.tb11975.x

Han J-H, Kim D-Y (1995) Analysis of the proportionality constant correlating the mean intercept length to the average grain size. Acta Metall Mater 43:3185–3188. https://doi.org/10.1016/0956-7151(95)00007-i

Idris MS, Osman RAM (2013) Structure refinement strategy of li-based complex oxides using GSAS-EXPGUI software package. Adv Mater Res 795:479–482. https://doi.org/10.4028/www.scientific.net/AMR.795.479

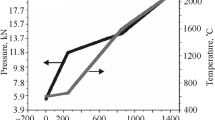

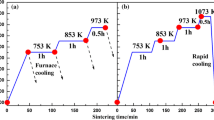

Zou J, Xu S, Chen J, Wang P, Yan C, Cao C, You Y, Lu J, Zhu L, Zhu Z, Lin J (2023) Effects of spark plasma sintering parameters on the microstructure of U3Si2 pellets. J Nucl Mater. https://doi.org/10.1016/j.jnucmat.2023.154649

Schlichting KW, Padture NP, Klemens PG (2001) Thermal conductivity of dense and porous yttria-stabilized zirconia. J Mater Sci 36:3003–3010. https://doi.org/10.1023/a:1017970924312

Benarosch A (2017) Development of U3Si2 pellets for LWR applications. Degree Project in Chemical Science and Engineering, Stockholm

Yan T, Xie D, Chen Z, Yang R, Zhu K, Jiang C, Ma C, Liu J, Wang X, Liu K, Luo L, Pan Q, Hu Y (2019) Initial oxidation of U3Si2 studied by in-situ XPS analysis. J Nucl Mater 520:1–5. https://doi.org/10.1016/j.jnucmat.2019.04.005

Harrison RW, Gasparrini C, Worth RN, Buckley J, Wenman MR, Abram T (2020) On the oxidation mechanism of U3Si2 accident tolerant nuclear fuel. Corros Sci. https://doi.org/10.1016/j.corsci.2020.108822

Yang JH, Kim DS, Kim D-J, Kim S, Yoon J-H, Lee HS, Koo Y-H, Song KW (2020) Oxidation and phase separation of U3Si2 nuclear fuel in high-temperature steam environments. J Nucl Mater. https://doi.org/10.1016/j.jnucmat.2020.152517

Johnson K, Ström V, Wallenius J, Lopes DA (2016) Oxidation of accident tolerant fuel candidates. J Nucl Sci Technol. https://doi.org/10.1080/00223131.2016.1262297

Mamiya M, Takei H, Kikuchi M, Uyeda C (2001) Preparation of fine silicon particles from amorphous silicon monoxide by the disproportionation reaction. J Cryst Growth 229:457–461. https://doi.org/10.1016/s0022-0248(01)01202-7

Brewer L, Edwards RK (2002) The stability of SiO solid and gas. J Phys Chem 58:351–358. https://doi.org/10.1021/j150514a015

Mamiya M, Kikuchi M, Takei H (2002) Crystallization of fine silicon particles from silicon monoxide. J Cryst Growth 237–239:1909–1914. https://doi.org/10.1016/s0022-0248(01)02244-8

Kapaklis V, Politis C, Poulopoulos P, Schweiss P (2005) Photoluminescence from silicon nanoparticles prepared from bulk amorphous silicon monoxide by the disproportionation reaction. Appl Phys Lett. https://doi.org/10.1063/1.2043246

Acknowledgements

This study was supported by the Frontier Science Key Program of the Chinese Academy of Sciences (Grant Number QYZDY-SSW-JSC016) and the Natural Science Foundation of Shanghai (Grant Nos. 20ZR1468800 and 21ZR1476300).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zou, JZ., Xu, SZ., Wang, P. et al. Thermal properties and oxidation behavior of densified U3Si2 pellets prepared by solid-phase metallurgy combined with spark plasma sintering. J Radioanal Nucl Chem 332, 4477–4488 (2023). https://doi.org/10.1007/s10967-023-09145-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-023-09145-3