Abstract

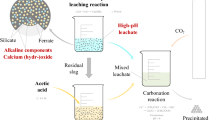

According to the difficult problem of disposal and recovery of uranium-containing waste slag, the leaching experiment was conducted by using the secondary countercurrent leaching process. The results showed that under conditions particle size of 1 mm, reaction time of 120 min, leaching temperature of 90 °C, nitric acid concentration of 429 g/L, liquid–solid ratio of 2.2:1, hydrogen peroxide dosage of 30 mL/L in primary leaching, then the temperature was switched to 130 °C during the secondary leaching. The leaching rate of uranium in alkali slag was 99.73% and the content of the uranium in insoluble slag was 0.788%.

Similar content being viewed by others

References

Costa Peluzo BMT, Kraka E (2022) Uranium: the nuclear fuel cycle and beyond. Int J Mol Sci 23:4655. https://doi.org/10.3390/ijms23094655

Sundaram CV, Mannan SL (1989) Nuclear fuels and development of nuclear fuel elements. Sadhana 14:21–57. https://doi.org/10.1007/bf02745341

Reynolds JG, Cooke GA, Page JS, Warrant RW (2018) Uranium-bearing phases in Hanford nuclear waste. J Radioanal Nucl Chem 316:289–299. https://doi.org/10.1007/s10967-018-5724-5

Ohashi Y, Murashita S, Nomura M (2014) Extraction of uranium from solid waste containing uranium and fluorine. Miner Eng 61:32–39. https://doi.org/10.1016/j.mineng.2014.03.003

Hyatt NC, Ojovan MI (2019) Special issue: materials for nuclear waste immobilization. Materials (Basel). 12:3611. https://doi.org/10.3390/ma12213611

Nathaniel SP, Alam MS, Murshed M, Mahmood H, Ahmad P (2021) The roles of nuclear energy, renewable energy, and economic growth in the abatement of carbon dioxide emissions in the G7 countries. Environ Sci Pollut Res Int 28:47957–47972. https://doi.org/10.1007/s11356-021-13728-6

Kiegiel K (2022) Storage and disposal options for nuclear waste. Energies 15:4665. https://doi.org/10.3390/en15134665

Abdelouas A (2006) Uranium mill tailings: geochemistry, mineralogy, and environmental impact. Elements 2:335–341. https://doi.org/10.2113/gselements.2.6.335

Paulillo A, Dodds JM, Palethorpe SJ, Lettieri P (2021) Reprocessing vs direct disposal of used nuclear fuels: the environmental impacts of future scenarios for the UK. Sustain Mater Technol 28:e00278. https://doi.org/10.1016/j.susmat.2021.e00278

Kurniawan TA, Othman MHD, Singh D, Avtar R, Hwang GH, Setiadi T, Lo W-h (2022) Technological solutions for long-term storage of partially used nuclear waste: a critical review. Ann Nucl Energy 166:108736. https://doi.org/10.1016/j.anucene.2021.108736

Rodríguez-Penalonga L (2017) A review of the nuclear fuel cycle strategies and the spent nuclear fuel management technologies. Energies 10:1235. https://doi.org/10.3390/en10081235

Gao F, Li M, Zhang X, Huang C, Wu X, Zhou Y, Fang Q (2020) Liberation mechanism of uranium from radioactive metallurgical waste containing uranium by a clean leaching method. JOM 72:3491–3501. https://doi.org/10.1007/s11837-020-04264-8

Long H, Zheng Y-j, Peng Y-l, He H-b (2020) Recovery of alkali, selenium and arsenic from antimony smelting arsenic-alkali residue. J Clean Prod 251:119673. https://doi.org/10.1016/j.jclepro.2019.119673

Xu L, Yang H, Liu Y, Zhou Y (2019) Uranium leaching using citric acid and oxalic acid. J Radioanal Nucl Chem 321:815–822. https://doi.org/10.1007/s10967-019-06673-9

Szolucha MM, Andrzej G (2017) A comparison of uranium recovery from low-grade ore by bioleaching and acid leaching. Physicochem Probl Miner Process 53:15. https://doi.org/10.5277/ppmp170111

Li M, Huang C-M, Zhang X-W, Gao F-Y, Wu X-Y, Fang Q, Tan W-F, Zhang D (2018) Extraction mechanism of depleted uranium exposure by dilute alkali pretreatment combined with acid leaching. Hydrometallurgy 180:201–209. https://doi.org/10.1016/j.hydromet.2018.07.021

Chen S, Wei X, Liu J, Sun Z, Chen G, Yang M, Liu Y, Wang D, Ma C, Kong D (2022) Weak acid leaching of uranium ore from a high carbonate uranium deposit. J Radioanal Nucl Chem 331:2583–2596. https://doi.org/10.1007/s10967-022-08323-z

Van Lien T, Dinh TT, Dung NTK (2020) Study on leaching systems and recovery for PALUA–PARONG low grade uranium sandstone ores. Hydrometallurgy 191:105164. https://doi.org/10.1016/j.hydromet.2019.105164

Wang X, Sun Z, Liu Y, Min X, Guo Y, Li P, Zheng Z (2019) Effect of particle size on uranium bioleaching in column reactors from a low-grade uranium ore. Bioresour Technol 281:66–71. https://doi.org/10.1016/j.biortech.2019.02.065

Ryon AD, Hurst FJ, Seeley FG (1977) Nitric acid leaching of radium and other significant radionuclides from uranium ores and tailings. Oak Ridge National Lab (ORNL), Oak Ridge. https://doi.org/10.2172/7219223

Manaa E-SA (2021) Uranium extraction from gattar granite sample after leaching using nitrate solution in presence of peroxide. Nucl Sci Eng 195:664–677. https://doi.org/10.1080/00295639.2020.1825899

Khalafalla MS (2022) Biotechnological recovery of uranium (VI) from Abu Zeneima spent ore residue using green lixiviant. J Radioanal Nucl Chem 331:2503–2513. https://doi.org/10.1007/s10967-022-08249-6

Wang X, Liu Y, Sun Z, Li J, Chai L, Min X, Guo Y, Li P, Zhou Z (2017) Heap bioleaching of uranium from low-grade granite-type ore by mixed acidophilic microbes. J Radioanal Nucl Chem 314:251–258. https://doi.org/10.1007/s10967-017-5406-8

Sadeghi MH, Outokesh M, Sharifi M, Zare MH (2021) Recovery of uranium from carbonaceous radioactive waste of the UF6 production line in a uranium conversion plant: laboratory and pilot plant studies. Hydrometallurgy 205:105747. https://doi.org/10.1016/j.hydromet.2021.105747

Bakry AR, Demerdash M, Manaa EA, Fatah AILAE (2021) Recovery of uranium and rare earth elements from western desert phosphate rocks with EDTA and nitric acid solutions. Radiochemistry 63:297–306. https://doi.org/10.1134/s1066362221030073

Fan S, Xin Q, Zhang Y, Zhao X, Liu X, Hao X, Hu E, Wang H, Lv J, Lei Z, Wang Q (2023) Efficient and clean release of uranium and zirconium in hazardous uranium purification waste by combined alkali decomposition and acid leaching process. J Environ Chem Eng 11(2):109382. https://doi.org/10.1016/j.jece.2023.109382

Mo X, Li X, Wen J (2019) Optimization of bioleaching of fluoride-bearing uranium ores by response surface methodology. J Radioanal Nucl Chem 321:579–590. https://doi.org/10.1007/s10967-019-06594-7

Kumagai Y, Takano M, Watanabe M (2017) Reaction of hydrogen peroxide with uranium zirconium oxide solid solution—Zirconium hinders oxidative uranium dissolution. J Nucl Mater 497:54–59. https://doi.org/10.1016/j.jnucmat.2017.10.050

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflict of interests, we do not have any possible conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, H., Wang, Q., Lei, Z. et al. The mechanism of secondary countercurrent leaching of uranium-containing alkali slag. J Radioanal Nucl Chem 332, 3827–3836 (2023). https://doi.org/10.1007/s10967-023-09049-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-023-09049-2