Abstract

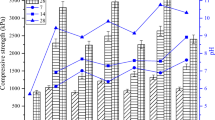

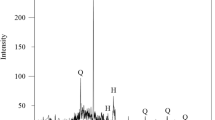

The uranium reconversion process is performed to convert concentrated UF6 into UO2. Ca(OH)2 is used to neutralize liquid waste generated during the uranium reconversion process, and all waste generated during this process is then collectively named lime waste. The present study aimed to improve cost-effectiveness and efficiency in lime waste treatment by replacing water, required in the cementation process, with concentrated liquid waste. The concentrate/cement ratio in the cementation process was set to range from 1.90 to 2.30, and the content of waste (lime + salt) ranged from 73.4 to 73.5 wt%. The optimum concentrate/cement ratio was determined to be 1.91, considering cost-effectiveness and safety. The structural stability of cement waste forms generated under the optimum operating conditions was evaluated according to the waste acceptance criteria (WAC). The feasibility of waste disposal was demonstrated by the evaluation of the leaching index of Cs, Sr, and Co.

Similar content being viewed by others

References

Dobrev L, Nonova T (2020) Determination of uranium content in ammonium uranyl carbonate (AUC) and triuranium octoxide (U3O8). J Radioanal Nucl Chem 326:1543–1550. https://doi.org/10.1007/s10967-020-07471-4

Neto JBS, De Carvalho EFU, Garcia RHL, Saliba-Silva AM, Riella HG, Durazzo M (2017) Production of uranium tetrafluoride from the effluent generated in the reconversion via ammonium uranyl carbonate. Nucl Eng Technol 49:1711–1716. https://doi.org/10.1016/j.net.2017.07.019

Sadeghi MH, Outokesh M, Sharifi M, Zare MH (2021) Recovery of uranium from carbonaceous radioactive waste of the UF6 production line in a uranium conversion plant: Laboratory and pilot plant studies. Hydrometallurgy 205:105747. https://doi.org/10.1016/j.hydromet.2021.105747

Okoshi M, Nakayama S (2015) Generation and characteristics of radioactive wastes. In: Nagasaki S, Nakayama S (eds) Radioactive waste engineering and management an advanced course in nuclear engineering. Springer, Tokyo, pp 17–46

Hwang D, Lee K, Choi Y, Hwang S, Park J (2004) Characteristics of lagoon sludge waste generated from an uranium conversion plant. J Radioanal Nucl Chem 260:327–333. https://doi.org/10.1023/b:jrnc.0000027105.83084.c7

Saliba-Silva A, de Carvalho EU , Riella H, Durazzo M (2011) Research reactor fuel fabrication to produce radioisotopes. https://www.intechopen.com/chapters/21643. Accesssed 7 Jan 2022.

Kent JA, Bommaraju TV, Barnicki SD (2017) Handbook of industrial chemistry and biotechnology. Springer, Cham. https://doi.org/10.1007/978-3-319-52287-6

Varlakov A, Zherebtsov A (2021) Innovative and conventional materials and designs of nuclear cementitious systems in radioactive waste management, in: sustainability of Life Cycle Management for Nuclear Cementation Based Technologies. Elsevier

Saleh HM, Eskander SB (2020) Innovative cement based materials for environmental protection and restoration, in new materials in civil engineering. Elsevier

Lang L, Song C, Xue L, Chen B (2020) Effectiveness of waste steel slag powder on the strength development and associated micro-mechanisms of cement-stabilized dredged sludge. Constr Build Mater 240:117975. https://doi.org/10.1016/j.conbuildmat.2019.117975

Li J, Chen L, Wang J (2021) Solidification of radioactive wastes by cement-based materials. Prog Nucl Energy 141:103957. https://doi.org/10.1016/j.pnucene.2021.103957

Kaneko M, Toyohara M, Satoh T, Noda T, Suzuki N, Sasaki N (2001) Development of high volume reduction and cement solidification technique for PWR concentrated waste. http://archive.wmsym.org/2001/41/41-7.pdf. Accesssed 7 Jan 2022.

França AAS (2021) Immobilization of liquid radioactive waste in cement. Braz J Radiat Sci. https://doi.org/10.15392/bjrs.v9i1A.1283

Rahman ROA, Rakhimov RZ, Rakhimova NR, Ojovan MI (2014) Cementitious materials for nuclear waste immobilization. Wiley

Arniella EF, Leslie JB (1990) Solidifying traps hazardous wastes. Chem Eng 97:92

Korean Industrial Standards (2017) Practice for mechanical mixing of hydraulic cement pastes and mortars of plastic consistency. https://standard.go.kr/KSCI/standardIntro/getStandardSearchView.do. Accessed 7 Jan 2022.

Korea Radioactive Wastes Agency (2008) Safety analysis report of low- and intermediate-level radioactive waste disposal facility.

El-Khoury M, Roziere E, Grondin F, Cortas R, Chehade FH (2022) Experimental evaluation of the effect of cement type and seawater salinity on concrete offshore structures. Constr Build Mater 322:126471. https://doi.org/10.1016/j.conbuildmat.2022.126471

Roy A, Bhattacharya J (2011) Microwave assisted synthesis of CaO nanoparticles and use in waste water treatment. https://briefs.techconnect.org/wp-content/volumes/Nanotech2011v3/pdf/946.pdf. Accesssed 7 Jan 2022.

Wang X, Shi L, Zhang J, Cheng J, Wang X (2018) In situ formation of surface-functionalized ionic calcium carbonate nanoparticles with liquid-like behaviours and their electrical properties. Royal Soc Open Sci 5:170732. https://doi.org/10.1098/rsos.170732

Shon JS, Lee HK, Kim GY, Kim TJ, Ahn BG (2022) Evaluation of disposal stability for cement solidification of lime waste. Materials 15(3):872. https://doi.org/10.3390/ma15030872

ANSI, Measurement of the leachability of solidified low-level radioactive wastes by a short-term test procedure, ANS 16.1 (2019) https://webstore.ansi.org/Standards/ANSI/ansians162019. Accessed 1 Aug 2022.

ANSI, Solid radioactive waste processing system for light-water-cooled reactor plants, ANS 55.1 (2021) https://webstore.ansi.org/Standards/ANSI/ansians552021. Accessed 1 Aug 2022.

Acknowledgements

This research was supported by Nuclear Energy R&D Program through the National Resarch Foundation of Korea (NRF) funded by Ministry of Science and ICT (2019M2C9A1059070).

Author information

Authors and Affiliations

Contributions

JSS: conceptualization, investigation, original draft preparation. HKL: investigation, writingreview and editing. GYK: resources. TJK: visualization, writing-reviewing. JSJ: validation.

Corresponding author

Ethics declarations

Conflicts of interest

There are no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shon, JS., Lee, HK., Kim, GY. et al. Evaluation of disposal stability of cement waste forms mixed with concentrated liquid waste for efficient treatment of AUC process waste. J Radioanal Nucl Chem 331, 4335–4345 (2022). https://doi.org/10.1007/s10967-022-08495-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-022-08495-8