Abstract

This paper examines the impact of using heavy water (D2O, D = deuterium) in cementitious materials as an alternative to conventional water (light water) for improvement in neutron radiography (NR) of cementitious materials. Cement pastes with two different water-to-cement ratios were made using heavy and light water. The macroscopic cross sections of heavy water, light water and ordinary portland cement were measured. Isothermal calorimetry, porosity, and non-evaporable water content were measured. NR measurements were also performed. The measured macroscopic cross section of the cement paste samples compared well with predictions made using a composite model based on Beer’s law.

Similar content being viewed by others

References

Shultis JK, Faw RE (2016) Fundamentals of nuclear science and engineering. CRC Press, Cambridge

Hassanein R, Lehmann E, Vontobel P (2005) Methods of scattering corrections for quantitative neutron radiography. Nucl Instrum Methods Phys Res, Sect A 542:353–360

Craft AE, Wachs DM, Okuniewski MA, Chichester DL, Williams WJ, Papaioannou GC, Smolinski AT (2015) Neutron radiography of irradiated nuclear fuel at Idaho National Laboratory. Phys Procedia 69:483–490

Cooper NJ, Santamaria AD, Becton MK, Park JW (2017) Neutron radiography measurements of in-situ PEMFC liquid water saturation in 2D & 3D morphology gas diffusion layers. Int J Hydrogen Energy 42:16269–16278

Ryzewski K, Herringer S, Bilheux H, Walker L, Sheldon B, Voisin S, Bilheux J-C, Finocchiaro V (2013) Neutron imaging of archaeological bronzes at the Oak Ridge national laboratory. Phys Procedia 43:343–351

Moradllo MK, Qiao C, Hall H, Ley MT, Reese SR, Weiss WJ (2019) Quantifying fluid filling of the air voids in air entrained concrete using neutron radiography. Cement Concr Compos 104:103407

Moradllo MK, Montanari L, Suraneni P, Reese SR, Weiss J (2018) Examining curing efficiency using neutron radiography. Transp Res Rec 2672:13–23

De Beer FC, Strydom WJ, Griesel EJ (2004) The drying process of concrete: a neutron radiography study. Appl Radiat Isot 61:617–623

Lucero CL (2015) Quantifying moisture transport in cementitious materials using neutron radiography, thesis in Civil Engineering. Purdue University, West Lafayette, IN, USA, p 130

Lucero CL, Weiss WJ, Bentz DP, Hussey DS, Jacobson DL (2015) Using neutron radiography to quantify water transport and the degree of saturation in air entrained cement based mortar. Phys Procedia. https://doi.org/10.1016/j.phpro.2015.07.077

Zeilinger A, Huebner R, (1975) Measurement of moisture motion under a temperature gradient in a concrete for SNR-300 using thermal neutrons.

Groot, C (1991) First minutes water transport from mortar to brick. Brick and Block Masonry, 71–78

Zhang P, Wittmann FH, Lura P, Müller HS, Han S, Zhao T (2018) Application of neutron imaging to investigate fundamental aspects of durability of cement-based materials: a review. Cem Concr Res 108:152–166

Tsuchiya N, Kanematsu M, Noguchi T (2014) Quick water movement around concrete cracks under unsaturated conditions. Constr Build Mater 67:95–99

Ghantous RM, Valadez-Carranza Y, Reese SR, Weiss WJ (2022) Drying behavior of 3D printed cementitious pastes containing cellulose nanocrystals. Cement 9:14

Zhang P, Wittmann FH, Zhao T, Lehmann E, Jin Z (2010) Visualization and quantification of water movement in porous cement-based materials by real time thermal neutron radiography: Theoretical analysis and experimental study. Science China Technol Sci 53:1198–1207

Li W, Pour-Ghaz M, Trtik P, Wyrzykowski M, Münch B, Lura P, Vontobel P, Lehmann E, Weiss WJ (2016) Using neutron radiography to assess water absorption in air entrained mortar. Constr Build Mater 110:98–105

Zhang P, Hou D, Liu Q, Liu Z, Yu J (2017) Water and chloride ions migration in porous cementitious materials: an experimental and molecular dynamics investigation. Cem Concr Res 102:161–174

Lucero CL, Spragg RP, Bentz DP, Hussey DS, Jacobson DL, Weiss WJ (2017) Neutron radiography measurement of salt solution absorption in mortar. ACI Mater J 114:149

Schröfl C, Nerella V N, Mechtcherine V (2018) Capillary water intake by 3D-printed concrete visualised and quantified by neutron radiography. In RILEM International Conference on Concrete and Digital Fabrication. p. 217–224.

Moradllo MK, Qiao C, Keys M, Hall H, Ley MT, Reese S, Weiss WJ (2019) Quantifying fluid absorption in air-entrained concrete using neutron radiography. ACI Mater J 116:213–226

Van Der Putten J, Azima M, Van den Heede P, Van Mullem T, Snoeck D, Carminati C, Hovind J, Trtik P, De Schutter G, Van Tittelboom K (2020) Neutron radiography to study the water ingress via the interlayer of 3D printed cementitious materials for continuous layering. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.119587

Ghantous RM, Fronczek B, Jablonski C, Bui V, Scaef S, Reese SR, Weiss WJ (2022) The influence of test parameters on the measured water permeability, submitted to ACEM

Kanematsu M, Maruyama I, Noguchi T, Iikura H, Tsuchiya N (2009) Quantification of water penetration into concrete through cracks by neutron radiography. Nucl Instrum Methods Phys Res, Sect A 605:154–158

Bouchelil L, Ghantous RM, Gwen C, Goodwin M N, Weiss W J, Moradllo M K (2022) Quantifying the impact of internally cured concrete on the duration of external curing using neutron radiography, Submitted to American concrete institue

Trtik P, Münch B, Weiss WJ, Kaestner A, Jerjen I, Josic L, Lehmann E, Lura PJ (2011) Release of internal curing water from lightweight aggregates in cement paste investigated by neutron and X-ray tomography. Nucl Instrum Methods Phys Res, Sect A 651:244–249

Villani C, Lucero C, Bentz D, Hussey D, Jacobson DL, Weiss WJ (2014) Neutron radiography evaluation of drying in mortars with and without shrinkage reducing admixtures. In American Concrete Institute Fall Meeting, Washington, DC (Vol. 26)

Moradllo MK, Ghantous RM, Quinn S, Aktan V, Reese S, Weiss WJ (2022) Quantifying drying and carbonation in calcium silicate-cement systems using neutron radiography. ACI Mater J 119(2):231–242

Wyrzykowski M, Trtik P, Münch B, Weiss J, Vontobel P, Lura P (2015) Plastic shrinkage of mortars with shrinkage reducing admixture and lightweight aggregates studied by neutron tomography. Cem Concr Res 73:238–245

Ghantous RM, Goodwin MN, Moradllo MKm Quinn S. Aktan V., Isgor OB, Weiss WJ (2022) Examining Carbonation of calcium silicate-based cements in real time using neutron radiography, submitted to American concrete institute

Brown D (2018) Evaluated Nuclear Data File. https://www-nds.iaea.org/exfor/endf.htm

ASTM, C150/C150M-19a: Standard Specification for Portland Cement. 2018: ASTM International, West Conshohocken, PA

Gadd MS (2007) LA-UR-07–5375: Characterization of the oregon state university neutron radiography facility. Los Alamos National Laboratory

Moradllo MK, Qiao C, Isgor B, Reese S, Weiss WJ (2018) Relating formation factor of concrete to water absorption. ACI Mater J 115(887–898):34

Moradllo MK, Reese SR, Weiss WJ (2019) Using neutron radiography to quantify the settlement of fresh concrete. Adv Civil Eng Mater 8:71–87

Hussey DS, Spernjak D, Weber AZ, Mukundan R, Fairweather J, Brosha EL, Davey J, Spendelow JS, Jacobson DL, Borup RL (2012) Accurate measurement of the through-plane water content of proton-exchange membranes using neutron radiography. J Appl Phys. https://doi.org/10.1063/14767118

Weiss J, Geiker MR, Hansen KK (2015) Using X-ray transmission/attenuation to quantify fluid absorption in cracked concrete. Int J Mater Struct Integrity 9:3–20

Kang M, Bilheux HZ, Voisin S, Cheng CL, Perfect E, Horita J, Warren JM (2013) Water calibration measurements for neutron radiography: application to water content quantification in porous media. Nucl Instrum Methods Phys Res, Sect A 708:24–31

Powers TC, Brownyard TL (1946) Studies of the physical properties of hardened Portland cement paste. J Proceed 43:101–132

ASTM, C1702: Standard Test Method for Measurement of Heat of Hydration of Hydraulic Cementitious Materials Using Isothermal Conduction Calorimetry. 2017: ASTM International, West Conshohocken, PA

Castro J, Varga IDL, Weiss J (2012) Using isothermal calorimetry to assess the water absorbed by fine LWA during mixing. J Mater Civ Eng 24:996–1005

De la Varga I, Castro J, Bentz DP, Zunino F, Weiss J (2018) Evaluating the hydration of high volume fly ash mixtures using chemically inert fillers. Constr Build Mater 161:221–228

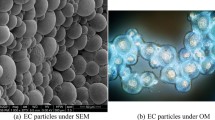

Qiao C (2021) Microstructural characterization of hydrated portland cement paste prepared with normal and heavy water cast at Oregon State University Located in Corvallis, Oregon. Report from DRP A twining company, DOI pending

Kim T, Olek J (2012) Effects of sample preparation and interpretation of thermogravimetric curves on calcium hydroxide in hydrated pastes and mortars. Transp Res Rec 2290:10–18

Linderoth O, Wadsö L, Jansen D (2021) Long-term cement hydration studies with isothermal calorimetry. Cement Concr Resear. https://doi.org/10.1016/j.cemconres.2020.106344

Parrott LJ, Geiker M, Gutteridge WA, Killoh D (1990) Monitoring Portland cement hydration: comparison of methods. Cem Concr Res 20:919–926

Königsberger M, Carette J (2020) Validated hydration model for slag-blended cement based on calorimetry measurements. Cement Concr Resear. https://doi.org/10.1016/j.cemconres.2019.105950

Pichler C, Lackner R (2020) Post-peak decelerating reaction of Portland cement: monitoring by heat flow calorimetry, modelling by Elovich-Landsberg model and reaction-order model. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2019.117107

Frølich L, Wadsö L, Sandberg P (2016) Using isothermal calorimetry to predict one day mortar strengths. Cem Concr Res 88:108–113

De Matos PR, Prudencio LR Jr, Pilar R, Gleize PJP, Pelisser F (2020) Use of recycled water from mixer truck wash in concrete: effect on the hydration, fresh and hardened properties. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2019.116981

Bogner A, Link J, Baum M, Mahlbacher M, Gil-Diaz T, Lützenkirchen J, Heberling F, Schäfer T, Ludwige HM, Dehna F, Müllera HS, Haist M (2020) Early hydration and microstructure formation of Portland cement paste studied by oscillation rheology, isothermal calorimetry, 1H NMR relaxometry, conductance and SAXS. Cement Concr Resear. https://doi.org/10.1016/j.cemconres.2020.105977

Acknowledgements

The authors gratefully acknowledge support for this work from the pooled fund study (Project No. U1117C) managed by the Oklahoma Department of Transportation, and from the National Science Foundation (Award No. 2129606). The authors would like to acknowlege Chunyu Qiao from DRP, a Twining Company who helped in the microscopic imaging. The contents of this paper reflect the views of the authors, who are responsible for the facts and the accuracy of the data presented herein. The contents do not necessarily reflect the official views or policies of the sponsors. These contents do not constitute a standard, specification, or regulation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Goodwin, M.N., Ghantous, R.M., Weiss, W.J. et al. Neutron radiography of cement paste made with light and heavy water. J Radioanal Nucl Chem 331, 5113–5121 (2022). https://doi.org/10.1007/s10967-022-08493-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-022-08493-w