Abstract

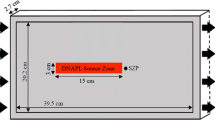

A mathematical model of co-decontamination process (1A) containing U(VI), Pu(IV), Zr(IV), and Ru(III) was developed with a high-performance Iteration of Extraction Equilibrium (ITEE) algorithm. ITEE algorithm not only guarantees the positive solution set but also possesses better computational efficiency than L-BFGS-B and fsolve algorithms. This model was used to study the effects of the HNO3 concentration and the location of the feed stage on the extraction and decontamination efficiencies. The results show HNO3 is beneficial to the extraction of U, Pu, and Zr. More extraction stages boost the extraction of U and Pu into the organic phase.

Similar content being viewed by others

References

Mckay HAC (1990) The PUREX process. Science and technology of tribuytl phosphate. CRC Press, Boca Raton

Ewing RC (2015) Long-term storage of spent nuclear fuel. Nat Mater 14(3):252–257. https://doi.org/10.1038/nmat4226

Geist A, Adnet J-M, Bourg S, Ekberg C, Galán H, Guilbaud P, Miguirditchian M, Modolo G, Rhodes C, Taylor R (2021) An overview of solvent extraction processes developed in Europe for advanced nuclear fuel recycling, part 1 — heterogeneous recycling. Sep Sci Technol 56(11):1866–1881. https://doi.org/10.1080/01496395.2020.1795680

Zabunogˇlu OH, Özdemir L (2005) Purex co-processing of spent LWR fuels: flow sheet. Ann Nucl Energy 32(2):151–162. https://doi.org/10.1016/j.anucene.2004.07.015

Bruno J, Ewing RC (2006) Spent nuclear fuel. Elements 2(6):343–349. https://doi.org/10.2113/gselements.2.6.343

McKibben JM (1984) Chemistty of the purex process. Radiochim Acta 36(1–2):3–16. https://doi.org/10.1524/ract.1984.36.12.3

Herbst RS, Baron P, Nilsson M (2011) Standard and advanced separation: PUREX processes for nuclear fuel reprocessing. Advanced Separation Techniques for Nuclear Fuel Reprocessing and Radioactive Waste Treatment. Elsevier, pp 141–175

Chen H, Taylor RJ, Jobson M, Woodhead DA, Boxall C, Masters AJ, Edwards S (2017) Simulation of neptunium extraction in an advanced PUREX process—model improvement. Solvent Extr Ion Exch 35(1):1–18. https://doi.org/10.1080/07366299.2016.1273684

Kolarik Z, Dressler P (1989) Extraction and coextraction of Tc(VII), Zr(IV), Np(IV.VI), Pa(V) and Nb(V) with tributyl phosphate from nitric acid solutions. Solvent Extr Ion Exch 7(4):625–644. https://doi.org/10.1080/07360298908962328

Dian JJ (1977) The behavior and control of ruthenium during reprocessing. Report No. CEA-R-4813 CEA. Paris, France

Boswell GGJ, Soentono S (1981) Ruthenium nitrosyl complexes in nitric acid solutions. J Inorg Nucl Chem 43(7):1625–1632. https://doi.org/10.1016/0022-1902(81)80350-8

Moeyaert P, Miguirditchian M, Masson M, Dinh B, Hérès X, De Sio S, Sorel C (2017) Experimental and modelling study of ruthenium extraction with tri-n-butylphosphate in the purex process. Chem Eng Sci 158:580–586. https://doi.org/10.1016/j.ces.2016.10.035

Puzikov EA, Zilberman BY, Fedorov YS, Blazheva IV, Kudinov AS, Goletskiy ND, Ryabkov DV (2015) A new approach to simulation of extraction equilibria in the purex process. Solvent Extr Ion Exch 33(4):362–384. https://doi.org/10.1080/07366299.2014.993238

Fletcher J, Hardy C (1963) Extraction of metal nitrates by TBP·HNO3. Nucl Sci Eng 16(4):421–427. https://doi.org/10.13182/NSE63-A26554

Verma PK, Mohapatra PK (2021) Ruthenium speciation in radioactive wastes and state-of-the-art strategies for its recovery: a review. Sep Purif Technol 275:119148. https://doi.org/10.1016/j.seppur.2021.119148

Svantesson I, Hagström I, Persson G, Liljenzin JO (1979) Distribution ratios and empirical equations for the extraction of elements in PUREX high level waste solution: I: TBP. J Inorg Nucl Chem 41(3):383–389. https://doi.org/10.1016/0022-1902(79)80151-7

Siczek A, Meisenhelder J (1980) Zirconium retention in 30% tributyl phosphate/n-dodecane. Radiochim Acta 27(4):217–221

Pruett DJ (1980) The solvent extraction behavior of ruthenium I-the nitric acid-tri-n-butyl phosphate system. Radiochim Acta 27(2):115–120. https://doi.org/10.1524/ract.1980.27.2.115

Sood DD, Patil SK (1996) Chemistry of nuclear fuel reprocessing: current status. J Radioanal Nucl Chem 203(2):547–573. https://doi.org/10.1007/BF02041529

Glatz JP, Bokelund H, Valkiers S (1984) Separation of fission products, nitric acid plutonium and uranium by extraction chromatography with TBP-polystyrene. Inorg Chim Acta 94(1–3):129–131. https://doi.org/10.1016/S0020-1693(00)94595-X

Groenier WS (1972) Calculation of the transient behavior of a dilute-PUREX solvent extraction process having application to the reprocessing of LMFBR fuels. Oak Ridge National Lab., Tenn., Tenn., United States. doi:https://doi.org/10.2172/4679651

Watson SB, Rainey RH (1975) Modifications of the SEPHIS computer code for calculating the Purex solvent extraction system. Oak Ridge National Lab., Tenn.(USA), Tenn., United States. doi:https://doi.org/10.2172/4167160

Watson SB, Rainey RH (1979) User's guide to the SEPHIS computer code for calculating the Thorex solvent extraction system. Oak Ridge National Lab., TN (USA), Tenn., United States. doi:https://doi.org/10.2172/6346841

Geldard JF, Beyerlein AL (1989) CUSEP—A new mathematical model of pulsed column contactors using the PUREX process. Nucl Technol 85(2):172–186. https://doi.org/10.13182/NT89-A34239

Gonda K, Fukuda S (1977) Calculation code MIXSET for Purex process. vol 10. Power Reactor and Nuclear Fuel Development Corp., PNCT-841–77–60 (in Japanese)

Gonda K, Oka K, Fukuda S (1979) Calculation code revised mixset for Purex process. vol 11. Power Reactor and Nuclear Fuel Development Corp., PNCT-841–79–26 (in Japanese)

Tachimori S (1994) EXTRA· M: a computing code system for analysis of the Purex process with mixer settlers for reprocessing. vol 25. Japan Atomic Energy Research Inst., JAERI-1331 (in Japanese)

Naito M, Suto T, Asakawa K, Kashiwagi E (1999) MIXSET-X: A Computer Code for Simulating the PUREX Solvent Extraction Process. JNC, TN8400 99 (005) (in Japanese)

Tsubata Y, Asakura T, Morita Y (2009) Development of a computer code, PARC, for simulation of solvent extraction process in reprocessing. Trans Atomic Energy Soc Jpn 8(3):211–220. https://doi.org/10.3327/taesj.J08.054 (in Japanese)

Sorel C, Montuir M, Pacary V, Roussel H, Dinh B, Baron P (2010) The PAREX code: a powerful tool to model and simulate solvent extraction operations. Paper presented at the Uranium 2010 The Future is U, Saskatoon, Aug 15–18, 2010

Yu T, He H, Hong Z, Liu Z, Li F, Ye G (2019) Computer simulation and software development of uranium/plutonium separation unit (1B) in PUREX process. Atomic Energy Sci Technol 53(2):193–199 (in Chinese)

Yu T, He H, Liu Z, Zhang L, Li Z, Zhao H, Ye G (2020) Transient behavior and mathematical model of solvent extraction process in mixer-settler. J Nucl Radiochem 42(4):214–225 (in Chinese)

Chen Y, He H, Tang H, Zhang C, Yu T (2012) Application status and prospect of computer simulation of purex. J Nucl Radiochem 34(4):193–200 (in Chinese)

Chen Y, He H, Zhang C, Chang L, Li R, Tang H, Yu T (2013) Computer simulation of technetium scrubbing section of purex process I. computer simulation and technical parameter analysis. J Nucl Radiochem 35(1):19–23 (in Chinese)

He H, Hu J, Zhang X, Xiao S, Zhu W, Wang F (2001) Reductive back-extraction of Pu(IV) with N, N-dimethylhydroxylamine and the development of the corresponding computation modeling. J Nucl Radiochem 23(2):65–71 (in Chinese)

He H, Li G, Chen H, Jiang D, Tang H (2008) Computer simulation of co-decontamination process in purex. Atomic Energy Sci Technol 42(9):784–789 (in Chinese)

Moré JJ, Garbow BS, Hillstrom KE (1980) User guide for MINPACK-1. https://doi.org/10.2172/6997568

Morales JL, Nocedal J (2011) Remark on “Algorithm 778: L-BFGS-B: Fortran subroutines for large-scale bound constrained optimization.” ACM Trans Math Softw 38(1):1–4. https://doi.org/10.1145/2049662.2049669

Zhu C, Byrd RH, Lu P, Nocedal J (1997) Algorithm 778: L-BFGS-B: fortran subroutines for large-scale bound-constrained optimization. ACM Trans Math Softw 23(4):550–560. https://doi.org/10.1145/279232.279236

Byrd RH, Lu P, Nocedal J, Zhu C (1995) A limited memory algorithm for bound constrained optimization. SIAM J Sci Comput 16(5):1190–1208. https://doi.org/10.1137/0916069

Dirks T (2020). Ruthenium speciation in extraction phases of nuclear fuel recycling processes. Material chemistry. Université Montpellier. NNT: 2020MONTS063.

Hardy C, Fairhurst D, McKay H, Willson A (1964) Extraction of water by tri-n-butyl phosphate. Trans Faraday Soc 60:1626–1636. https://doi.org/10.1039/TF9646001626

Natarajan R, Pandey NK, Vijayakumar V, Subbarao RV (2012) Modeling and simulation of extraction flowsheet for FBR fuel reprocessing. Procedia Chem 7:302–308. https://doi.org/10.1016/j.proche.2012.10.048

Alcock K, Bedford FC, Hardwick WH, McKay HAC (1957) Tri-n-butyl phosphate as an extracting solvent for inorganic nitrates—I: zirconium nitrate. J Inorg Nucl Chem 4(2):100–105. https://doi.org/10.1016/0022-1902(57)80091-8

Orth DA, Olcott TW (1963) Purex process performance versus solvent exposure and treatment. Nucl Sci Eng 17(4):593–612. https://doi.org/10.13182/NSE63-A18452

Baldwin AG, Bridges NJ, Braley JC (2016) Distribution of fission products into tributyl phosphate under applied nuclear fuel recycling conditions. Ind Eng Chem Res 55(51):13114–13119. https://doi.org/10.1021/acs.iecr.6b04056

Matsumoto S, Uchiya G, Ozawa M, Kobayashi Y, Shirato K (2003) Research committee on ruthenium and technetium chemistry in PUREX system, organized by the atomic energy society of Japan. Radiochemistry 45(3):219–224. https://doi.org/10.1023/A:1026047722973

Dileep CS, Jagasia P, Dhami PS, Achuthan PV, Dakshinamoorthy A, Tomar BS, Munshi SK, Dey PK (2008) Distribution of technetium in PUREX process streams. Desalination 232(1–3):157–165. https://doi.org/10.1016/j.desal.2007.11.053

Benedict M, Pigford TH, Levi HW (1981) Nuclear chemical engineering. McGraw-Hill Education, New York, United States

Zilberman B, Fedorov Y, Puzikov E, Blazheva I (2008) New data on joint extraction of nitric acid, Uranium(VI) and tetravalent elements by diluted TBP and new approach to modeling of their distribution

Dirks T, Dumas T, Solari PL, Charbonnel M-CJI, Research EC (2019) Ruthenium nitrosyl structure in solvent extraction systems: a comparison of tributyl phosphate, tetrabutyl urea, N-methyl, N-octyl ethylhexanamide, and N, N, N′, N′-tetraoctyl diglycolamide. Ind Eng Chem Res 58(32):14938–14946. https://doi.org/10.1021/acs.iecr.9b02555

Moeyaert P (2016) Etude expérimentale et modélisation des mécanismes d’extraction des produits de fission et des actinides mineurs par des extractants de la classe des monoamides. Montpellier. (in French)

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grant 11775214.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no potential competing interests about the work in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Guo, Z., Tang, J., Yang, Y. et al. Mathematical modeling of the co-decontamination process in PUREX. J Radioanal Nucl Chem 331, 2955–2966 (2022). https://doi.org/10.1007/s10967-022-08377-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-022-08377-z