Abstract

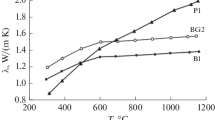

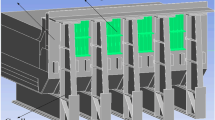

The diameter of the cylindrical waste form must be optimized through the estimated centerline temperature for thermally stable disposal. Salt wastes generated from pyrochemical processes were dechlorinated and vitrified using a universal silica alumina phosphate (U-SAP) glass system. The thermal properties of the waste form were analyzed, and centerline temperatures were calculated based on the analyzed thermal properties to optimize the diameter. Calculation of the centerline temperature was carried out using a steady-state conduction equation in an infinitely long cylindrical waste form. In all cases, the centerline temperatures of the U-SAP below a diameter of 0.4 m were estimated to be below 480 °C.

Similar content being viewed by others

References

Choi JH, Eun HC, Lee KR, Cho IH, Lee TK, Park HS, Ahn DH (2016) Fabrication of rare earth calcium phosphate glass waste forms for the immobilization of rare earth phosphates generated from pyrochemical process. J Non-Cryst Solids 434:79–84

Lee HS, Park GI, Kang KH, Hur JM, Kim JG, Ahn DH, Cho YZ, Kim EH (2011) Pyroprocessing technology development at KAERI. Nucl Eng Technol 43:317–328

Lee H, Park GI, Lee JW, Kang KH, Hur JM, Kim JG, Paek S, Kim IT, Cho IJ (2013) Current status of pyroprocessing development at KAERI. Sci Technol Nucl Install 1–11

Lexa D, Leibowitz L, Kropf J (2000) On the reactive occlusion of the (uranium trichloride + lithium chloride + potassium chloride) eutectic salt in zeolite 4A. J Nucl Mater 279:57–64

Lambregts MJ, Frank SM (2003) Characterization of cesium containing glass-bonded ceramic waste forms. Microporous Mesoporous Mater 64:1–9

Ebert WL, Lewis MA, Johnson SG (2002) The precision of product consistency tests conducted with a glass-bonded ceramic waste form. J Nucl Mater 305:37–51

Morss LR, Lewis MA, Richmann MK, Lexa D (2000) Cerium, uranium, and plutonium behavior in glass-bonded sodalite, a ceramic nuclear waste form. J Alloys Compd. 303:42–48

Richmann MK, Reed DT, Kropf AJ, Aase SB, Lewis MA (2001) EXAFS/XANES studies of plutonium-loaded sodalite/glass waste forms. J Nucl Mater 297:303–312

Lei P, Yao T, Gong B, Zhu W, Ran G, Lian J (2020) Spark plasma sintering-densified vanadinite apatite-based chlorine waste forms with high thermal stability and chlorine confinement. J Nucl Mater 528:151857

Donald IW, Metcalfe BL, Fong SK, Gerrard LA, Strachan DM, Scheele RD (2007) A glass-encapsulated calcium phosphate wasteform for the immobilization of actinide-, fluoride-, and chloride-containing radioactive wastes from the pyrochemical reprocessing of plutonium metal. J Nucl Mater 361:78–93

Leturcq G, Grandjean A, Rigaud D, Perouty P, Charlot M (2005) Immobilization of fission products arising from pyrometallurgical reprocessing in chloride media. J Nucl Mater 347:1–11

Bekaert E, Montagne L, Palavit G, Delevoye L, Kunegel A, Wattiaux A (2006) Conversion of tin and alkali chlorides to phosphates and vitrification into silicate glasses. J Non-Cryst Solids 352:4112–4121

Riley BJ, Rieck BT, McCloy JS, Crum JV, Sundaram SK, Vienna JD (2012) Tellurite glass as a waste form for mixed alkali-chloride waste streams: candidate materials selection and initial testing. J Nucl Mater 424(1–3):29–37

Park HS, Kim IT, Cho YZ, Eun HC, Lee HS (2008) Stabilization/solidification of radioactive salt waste by using x SiO2−y Al2O3−z P2O5 (SAP) material at molten salt state. Environ Sci Technol 42(24):9357–9362

Park HS, Cho IH, Eun HC, Kim IT, Cho YZ, Lee HS (2011) Characteristics of wasteform composing of phosphate and silicate to immobilize radioactive waste salts. Environ Sci Technol 45(5):1932–1939

Cho IH, Park HS, Ahn SN, Kim IT, Cho YZ (2012) Stabilization/Solidification of Radioactive LiCl–KCl Waste Salt by Using SiO2–Al2O3–P2O5 (SAP) inorganic composite: part 1. Dechlorination behavior of LiCl–KCl and characteristics of consolidation. J Nucl Fuel Cycle Waste Technol 10:45–53

Ahn SN, Park HS, Cho IH, Kim IT, Cho YZ (2012) Stabilization/solidification of radioactive LiCl–KCl waste salt by using SiO2–Al2O3–P2O5 (SAP) inorganic composite: part 2. The effect of SAP composition on stabilization/solidification. J Nucl Fuel Cycle Waste Technol 10:27–36

Cho IH, Park HS, Lee KR, Choi JH, Kim IT, Hur JM, Lee YS (2017) Treatment of radioactive waste salt by using synthetic silica-based phosphate composite for de-chlorination and solidification. J Nucl Mater 493:388–397

Lee KR, Park HS, Cho IH, Choi JH, Eun HC, Lee TK, Han SY, Ahn DH (2017) De-chlorination and solidification of radioactive LiCl waste salt by using SiO2–Al2O3–P2O5 (SAP) inorganic composite including B2O3 component. Korean J of Chem Eng 34:2390–2396

Lee KR, Riley BJ, Park HS, Choi JH, Han SY, Hur JM, Peterson JA, Zhu Z, Schreiber DK, Kruska K, Olszta MJ, Lee Ki Rak, Riley BJ, Park HS, Choi JH, Han SY, Hur JM, Peterson JA (2019) Investigation of physical and chemical properties for upgraded SAP (SiO2Al2O3P2O5) waste form to immobilize radioactive waste salt. J Nucl Mater 515:382–391

Spilman DB, Hench LL, Clark DE (1986) Devitrification and subsequent effects on the leach behavior of a simulated borosilicate nuclear waste glass. Nucl Chem Waste Manag 6:107–119

Gauld I, Hermann OW, Westfall RM (1998) ORIGEN-S: SCALE system module to calculate fuel depletion, actinide transmutation, fission product buildup and decay, and associated radiation source terms. Vol. II, Sect. F7 of SCALE: a modular code system for performing standardized computer analyses for licensing evaluation, NUREG/CR-0200, Rev 6

Choi JH, Eun HC, Lee TK, Lee KR, Han SY, Jeon MK, Park HS, Ahn DH (2017) Estimation of centerline temperature of the waste form for the rare earth waste generated from pyrochemical process. J Nucl Mater 483:82–89

Park GI, Jeon MK, Choi JH, Lee KR, Han SY, Kim IT, Cho YZ, Park HS (2019) Recent progress in waste treatment technology for pyroprocessing at KAERI. J Nucl Fuel Cycle Waste Technol 17(3):279–298

Hrma P (2010) Crystallization during processing of nuclear waste glass. J Non-Cryst Solids 356:3019–3025

Acknowledgements

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIP) (NRF-2017M2A8A5015082).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, C.W., Choi, JH., Park, HS. et al. Centerline temperature of the U-SAP waste form for sequestration of salt waste generated from the pyrochemical process. J Radioanal Nucl Chem 328, 65–70 (2021). https://doi.org/10.1007/s10967-020-07542-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-020-07542-6