Abstract

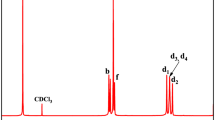

As a typical biodegradable material, poly(lactic acid) (PLA) has great development potential in fields such as packaging, textiles and biomedical applications due to its high modulus and strength as well as excellent biocompatibility. However, the inherent brittleness and poor toughness of PLA significantly limit its widespread application. In this study, a biodegradable aliphatic–aromatic copolyester called poly(ethylene adipate-co-terephthalate) (PEAT) was synthesized using the industrially well-established direct esterification method. PEAT demonstrated excellent flexibility and extremely high fracture elongation. Its fracture elongation exceeded 900%, making it a highly ductile material with exceptional toughness. Given the complementary nature of PLA and PEAT, blending PLA with PEAT becomes a natural choice for improving the performance of PLA. The influence of the addition of PEAT on the mechanical properties, thermal performance, crystallization, phase morphology and rheological behavior of the blends was thoroughly investigated. With the addition of PEAT, the fracture mode changed from brittle fracture of the neat PLA to ductile fracture of the blends as illustrated by tensile test. The best toughening effect on PLA was achieved at a PEAT content of 30 wt%, with the elongation at break increasing from 6.7% for neat PLA to 359% for the binary blend, an improvement of 53 times. Additionally, the impact strength also increased from 4.4 kJ/m2 to 10.5 kJ/m2, an increase of 138%. DSC revealed that PEAT had a certain influence on the crystallization behavior of PLA. SEM showed that the PEAT toughening mechanism was primarily attributed to a shear yielding mechanism triggered by debonding cavitation.

Similar content being viewed by others

Data availability

Author elects to not share data.

References

Gonzalez-Lopez ME, De Jesus Calva-Estrada S, Gradilla-Hernandez MS, Barajas-Alvarez P (2023) Current trends in biopolymers for food packaging: a review. Front Sustainable Food Syst. https://doi.org/10.3389/fsufs.2023.1225371

Wang X, Pan H, Jia S, Wang Z, Tian H, Han L, Zhang H (2022) In-situ reaction compatibilization modification of poly(butylene succinate-co-terepht-halate)/polylactide acid blend films by multifunctional epoxy compound. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2022.06.026

Mukherjee C, Varghese D, Krishna JS, Boominathan T, Rakeshkumar R, Dineshkumar S, Brahmananda Rao CVS, Sivaramakrishna A (2023) Recent advances in biodegradable polymers-properties, applications and future pros-pects. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2023.112068

Xu P-Y, Wang P-L, Liu T-Y, Zhen Z-C, Lu B, Huang D, Wang G-X, Ji J-H (2023) All-natural environmentally degradable poly(butylene terephthalat-e-co-caprolactone): a theoretical and experimental study of its degradation properties and mechanisms. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2023.165980

Petkoska AT, Daniloski D, Cunha NMD, Naumovski N, Broach AT (2021) Edible packaging: sustainable solutions and novel trends in food packaging. Food Res Int. https://doi.org/10.1016/j.foodres.2020.109981

Kristine VA (2023) Polysaccharides for biodegradable packaging materials: past, present, and future (brief review). Polymers. https://doi.org/10.3390/polym15020451

Chan Q-H, Alias SA, Quek SW, Ng CY, Marsilla KIK (2023) A review of the preparations, properties, and applications of smart biodegradable polymers. Polym-Plast Tech Mat. https://doi.org/10.1080/25740881.2023.2204954

Momeni S, Craplewe K, Safder M, Luz S, Sauvageau D, Elias A (2023) Accelerating the biodegradation of poly(lactic acid) through the inclusion o-f plant fibers: a review of recent advances. Acs Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.3c04240

Coltelli M-B, Aliotta L, Fasano G, Miketa F, Brkić F, Alonso R, Romei M, Cinelli P, Canesi I, Gigante V, Lazzeri A (2023) Recyclability studies on poly(lactic acid)/poly(butylene succinate-co-adipate) (PLA/PBSA) biobase-d and biodegradable films. Macromol Mater Eng. https://doi.org/10.1002/mame.202300136

Yang R, Cai C, Han X, Chen Z, Gu G, Zhang C, Zou G, Li J (2023) S-upertough and biodegradable poly(lactic acid) blends with hard-soft core-shell unsaturated poly(ether-ester) through self-vulcanization. Macromolecules. https://doi.org/10.1021/acs.macromol.3c01126

Chen K, Zhou C, Yao L, Jing M, Liu C, Shen C, Wang Y (2023) Phase morphology, rheological behavior and mechanical properties of supertough biobased poly(lactic acid) reactive ternary blends. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2023.127079

Gomez-Caturla J, Tejada-Oliveros R, Ivorra-Martinez J, Garcia-Sanoguera D, Balart R, Garcia-Garcia D (2023) Development and characterization of new environmentally friendly polylactide formulations with terpenoid-based plasticizers with improved ductility. J Polym Environ. https://doi.org/10.1007/s10924-023-03000-y

Ming M, Zhou Y, Wang L, Zhou F, Zhang Y (2022) Effect of polycarbodiimide on the structure and mechanical properties of PLA/PBAT blends. J Polym Res Https. https://doi.org/10.1007/s10965-022-03227-8

Chen Y, Zhang J, Zhang Y, Cao W, Liu X, Bao J, Zhang X, Chen W (2023) Poly(l-lactide)-b-poly(ε-caprolactone)-b-poly(d,l-lactide) copolymers with enhanced toughness and strength by regulating crystallization and phase separation. J Polym Sci. https://doi.org/10.1002/pol.20230425

Wang G, Zhang L, Chi X (2023) Ductile poly(lactic acid)-based blends de-rived from poly(butylene succinate-co-butylene 2,5-thiophenedicarboxylate): structures and properties. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2023.123702

Duan K, Zhen W (2019) The synthesis of poly(lactic acid)-fulvic acid graft polymer and its effect on the crystallization and performance of poly(lactic acid). Polym-Plast Tech Mat. https://doi.org/10.1080/25740881.2019.1587768

Musa L, Kumar NK, Abd Rahim SZ, Mohamad Rasidi MS, Watson Rennie AE, Rahman R, Kanani AU, Azrem Azmi A (2022) A review on the p-otential of polylactic acid based thermoplastic elastomer as filament materi-Al for fused deposition modelling. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2022.08.057

Farsetti S, Cioni B, Lazzeri A (2011) Physico-mechanical properties of bio-degradable rubber toughened polymers. Macromol Symp. https://doi.org/10.1002/masy.201150311

Jiang L, Wolcott MP, Zhang JW (2006) Study of biodegradable polylactide/poly(butylene adipate-co-terephthalate) blends. Biomacromol. https://doi.org/10.1021/bm050581q

Deng Y, Yu C, Wongwiwattana P, Thomas NL (2018) Optimising ductility of poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends through co-continuous phase morphology. J Polym Environ. https://doi.org/10.1007/s10924-018-1256-x

Diao X, Zhang C, Weng Y (2022) Properties and degradability of poly(butylene adipate-co-terephthalate)/calcium carbonate films modified by polyethylene glycol. Polymers. https://doi.org/10.3390/polym14030484

De Matos Costa AR, Crocitti A, Hecker De Carvalho L, Carroccio SC, Cerruti P, Santagata G (2020) Properties of biodegradable films based on poly(butylene succinate) (PBS) and poly(butylene adipate-co-terephthalate) (PBAT) blends. Polymers. https://doi.org/10.3390/polym12102317

Letwaba J, Muniyasamy S, Lekalakala R, Mavhungu L, Mbaya R (2024) Design of compostable toughened PLA/PBAT blend with algae via reactive compatibilization: the effect of algae content on mechanical and thermal properties of bio-composites. J Appl Polym Sci. https://doi.org/10.1002/app.55204

Jia S-L, Wang X-Y, Zhang Y, Yan X, Pan H, Zhan Y, Han L, Zhang H, Dong L (2023) Superior toughened biodegradable poly(l-lactic acid)-based blends with enhanced melt strength and excellent low-temperature toughness via in situ reaction compatibilization. Chin J Polym Sci. https://doi.org/10.1007/s10118-022-2862-6

Muthuraj R, Misra M, Mohanty AK (2014) Biodegradable poly(butylene succinate) and poly(butylene adipate-co-terephthalate) blends: reactive extrusion and performance evaluation. J Poly Environ. https://doi.org/10.1007/s10924-013-0636-5

Wang X, Peng S, Chen H, Yu X, Zhao X (2019) Mechanical properties, r-heological behaviors, and phase morphologies of high-toughness PLA/PBAT blends by in-situ reactive compatibilization. Compos Part B-eng. https://doi.org/10.1016/j.compositesb.2019.107028

Wu F, Misra M, Mohanty AK (2020) Sustainable green composites from b-iodegradable plastics blend and natural fibre with balanced performance: synergy of nano-structured blend and reactive extrusion. Compos Sci Technol. https://doi.org/10.1016/j.compscitech.2020.108369

Li Y, Han C, Xiao L, Yu Y, Zhou G, Xu M (2021) Miscibility, morphology, and properties of poly(butylene succinate)/poly(vinyl acetate) blends. Colloid Polym Sci. https://doi.org/10.1007/s00396-020-04773-7

Ma F, Wang B, Leng X, Wang Y, Sun Z, Wang P, Sang L, Wei Z (2022) Biodegradable PBAT/PLA/CaCO3 blowing films with enhanced mechanical and barrier properties: investigation of size and content of CaCO3 particles. Macromo Mater Eng. https://doi.org/10.1002/mame.202200135

Li K, Peng J, Turng L-S, Huang H-X (2011) Dynamic rheological behavior and morphology of polylactide/poly(butylenes adipate-co-terephthalate) blends with various composition ratios. Adv Polym Tech. https://doi.org/10.1002/adv.20212

Ding Y, Lu B, Wang P, Wang G, Ji J (2017) PLA-PBAT-PLA tri-block co-polymers: effective compatibilizers for promotion of the mechanical and r-heological properties of PLA/PBAT blends. Polym Degrad Stabil. https://doi.org/10.1016/j.polymdegradstab.2017.11.012

Jiang G, Wang F, Zhang S, Huang H (2020) Structure and improved properties of PPC/PBAT blends via controlling phase morphology based on melt viscosity. J Appl Polym Sci. https://doi.org/10.1002/app.48924

Jiang L, Wolcott MP, Zhang J (2006) Study of biodegradable polylactide/p-oly(butylene adipate-co-terephthalate) blends. Biomacromol. https://doi.org/10.1021/bm050581q

Teamsinsungvon A, Ruksakulpiwat Y, Jarukumjorn K (2013) Preparation an-d characterization of poly(lactic acid)/poly(butylene adipate-co-terepthalate) blends and their composite. Polym-Plast Tech Mat. https://doi.org/10.1080/03602559.2013.820746

Li W, Sun C, Li C, Xu Y, Tan H, Zhang Y (2021) Preparation of effective ultraviolet shielding poly(lactic acid)/poly(butylene adipate-co-terephthalate) degradable composite film using co-precipitation and hot-pressing method. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2021.09.097

Li X, Yan X, Yang J, Pan H, Gao G, Zhang H, Dong L (2018) Improvement of compatibility and mechanical properties of the poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends and films by reactive extrusion with chain extender. Polym Eng Sci. https://doi.org/10.1002/pen.24795

Rowland HD, King WP, Pethica JB, Cross GLW (2008) Molecular confin-ement accelerates deformation of entangled polymers during squeeze flow. Sci. https://doi.org/10.1126/science.1157945

Si L, Massa MV, Dalnoki-Veress K, Brown HR, Jones RAL (2005) Chain entanglement in thinfreestanding polymer films. Phys Rev Lett. https://doi.org/10.1103/PhysRevLett.94.127801

Zhang N, Wang Q, Ren J, Wang L (2009) Preparation and properties of b-iodegradable poly(lactic acid)/poly(butylene adipate-co-terephthalate) blend with glycidyl methacrylate as reactive processing agent. J Mater Sci. https://doi.org/10.1007/s10853-008-3049-4

Kishi H, Shi YB, Huang J, Yee AF (1998) Ductility and toughenability St-Udy of epoxy resins under multiaxial stress states. J Mater Sci. https://doi.org/10.1023/A:1013222421843

Ritchie RO (1999) Mechanisms of fatigue-crack propagation in ductile and brittle solids. Int J Fract. https://doi.org/10.1023/A:1018655917051

Jiang L, Liu B, Zhang J (2009) Properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/nanoparticle ternary composites. Ind Eng Chem Res. https://doi.org/10.1021/ie900576f

Huang Q, Hiyama M, Kabe T, Kimura S, Iwata T (2020) Enzymatic self-biodegradation of poly(l-lactic acid) films by embedded heat-treated and im-mobilized proteinase k. Biomacromol. https://doi.org/10.1021/acs.biomac.0c00759

Zhang SJ, Tang YW, Cheng LH (2013) Biodegradation behavior of PLA/PBS blends. AMR. https://doi.org/10.4028/www.scientific.net/amr.821-822.937

Chai X, He C, Liu Y, Niyitanga E, Wang L, Zhang W (2023) Degradation of wheat straw/polylactic acid composites with and without sodium alginate in natural soil and the effects on soil microorganisms. J Appl Polym Sci. https://doi.org/10.1002/app.53447

Ali SS, Elsamahy T, Al-Tohamy R, Zhu D, Mahmoud Y, Koutra E, Metwally M, Kornaros M, Sun J (2021) Plastic wastes biodegradation: Mechanis-ms, challenges and future prospects. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2021.146590

Acknowledgements

This research was supported by The Key Laboratory of Advanced Polymeric Materials of Shanghai.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, J., He, Z., Yin, W. et al. Enhancing the toughness of poly(lactic acid) with a novel, highly flexible and biodegradable polyester: poly(ethylene adipate-co-terephthalate) terephthalate. J Polym Res 31, 151 (2024). https://doi.org/10.1007/s10965-024-03992-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-024-03992-8