Abstract

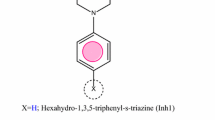

It is of great significance to understand the diffusion rate of the volatile corrosion inhibitor (VCI) in the VCI films for corrosion inhibition. The diffusion behavior of 1,2,3-Benzotriazole (BTA) in pure low density polyethylene (LDPE) and VCIs/LDPE blends was investigated using molecular dynamics (MD) simulation at 310, 328 and 353 K temperatures. The temperature dependence and diffusion property of BTA in LDPE were revealed. Subsequently, the accuracy of the MD simulations was confirmed by comparing the diffusion coefficients obtained from the MD simulations with those obtained from the experiments. The fractional free volume, interaction energy between BTA and VCIs/LDPE, activation energy of BTA and the self-diffusion behavior of LDPE on the diffusion of BTA were explored, which illustrated the microscopic diffusion mechanism of BTA in LDPE. Results showed that the diffusion coefficients of BTA increased with increasing temperature, increasing free volume and the more flexible chain of LDPE, while the increase in the interaction energy between BTA and VCIs/LDPE slowed down the diffusion of BTA. It can be concluded that the increase in the interaction energy between BTA and the system, the activation energy of BTA and the formation of H-bonds due to the addition of other VCIs led to the decrease in the diffusion coefficients of BTA. The strong molecular interactions between BTA and VCIs were the main reason for the decrease in the BTA diffusion coefficients. Adjusting the formulation of the VCI films can provide new ideas for regulating the BTA diffusion rate, which is beneficial for extending the corrosion inhibition time of BTA.

Similar content being viewed by others

Data availability

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- LDPE:

-

Low density polyethylene

- BTA:

-

Benzotriazole

- VCI:

-

Volatile corrosion inhibitor

- MD:

-

Molecular dynamics

- MSD:

-

Mean square displacement

- RDF:

-

Radial distribution function

- vdW:

-

Van der Waals

- AR:

-

Analytical reagent

- LP:

-

Laboratory pure

References

Merimi I, Bitari A, Kaddouri Y, Rezki N, Mohamed M, Touzani R, Hammouti B (2022) Metal corrosion inhibition by triazoles: A review. Int J Corros Scale Inhib 11:524–540. https://doi.org/10.17675/2305-6894-2022-11-2-4

Ammar S, Ma IAW, Muhammad FMS, Bashir S, Selvaraj M, Assiri MA, Ramesh K, Ramesh S (2020) Electrochemical studies of 1,2,3-Benzotriazole inhibitor for acrylic-based coating in different acidic media systems. J Polym Res 27:142. https://doi.org/10.1007/s10965-020-02130-4

Chen FX, Jin ZQ, Wang ED, Wang LQ, Jiang YD, Guo PF, Gao XY, He XY (2021) Relationship model between surface strain of concrete and expansion force of reinforcement rust. Sci Rep 11:4208. https://doi.org/10.1038/s41598-021-83376-w

Valdez B, Schorr M, Cheng N, Beltran E, Salinas R (2018) Technological applications of volatile corrosion inhibitors. Corros Rev 36:227–238. https://doi.org/10.1515/corrrev-2017-0102

Bastidas DM, Cano E, Mora EM (2005) Volatile corrosion inhibitors: a review. Anti-Corros Methods Mater 52:71–77. https://doi.org/10.1108/00035590510584771

Raja PB, Ismail M, Ghoreishiamiri S, Mirza J, Ismail MC, Kakooei S, Rahim AA (2016) Reviews on corrosion inhibitors: a short view. Chem Eng Commun 203:1145–1156. https://doi.org/10.1080/00986445.2016.1172485

Ebadi-Dehaghani H (2016) Diffusion of 1,2,3-Benzotriazole as a volatile corrosion inhibitor through common polymer films using the molecular dynamics simulation method. J Macromol Sci B 55:310–318. https://doi.org/10.1080/00222348.2016.1146979

Gangopadhyay S, Mahanwar PA (2018) Recent developments in the volatile corrosion inhibitor (VCI) coatings for metal: a review. J Coat Technol Res 15:789–807. https://doi.org/10.1007/s11998-017-0015-6

Basitnezhad F, Ebadi-Dehaghani H (2021) Controlled release of novel volatile corrosion inhibitor (VCI) nanoparticles incorporated in low density Polyethylene (LDPE) films for steel coverings: correlation of experimental results with molecular dynamics simulation. J Macromol Sci Part B: Phys 60:416–434. https://doi.org/10.1080/00222348.2020.1855839

Lu LJ, Cheng C, Xu L, Pan L, Xia HF, Lu LX (2022) Migration of antioxidants from food-contact rubber materials to food simulants. J Food Eng 318:110904. https://doi.org/10.1016/j.jfoodeng.2021.110904

Bi H, Burstein GT, Rodriguez BB, Kawaley G (2016) Some aspects of the role of inhibitors in the corrosion of copper in tap water as observed by cyclic voltammetry. Corros Sci 102:510–516. https://doi.org/10.1016/j.corsci.2015.11.005

Onyeachu IB, Obot IB, Sorour AA, Abdul-Rashid MI (2019) Green corrosion inhibitor for oilfield application I: Electrochemical assessment of 2-(2-pyridyl) benzimidazole for API X60 steel under sweet environment in NACE brine ID196. Corros Sci 150:183–193. https://doi.org/10.1016/j.corsci.2019.02.010

Luchkin AY, Goncharova OA, Arkhipushkin A, Andreev NN, Kuznetsov YI (2020) The effect of oxide and adsorption layers formed in 5-Chlorobenzotriazole vapors on the corrosion resistance of copper. J Taiwan Inst Chem E 117:231–241. https://doi.org/10.1016/j.jtice.2020.12.005

Goncharova OA, Luchkin AY, Andreeva NP, Kasatkin VE, Vesely SS, Andreev NN, Kuznetsov YI (2022) Mutual effect of components of protective films applied on copper and brass from octadecylamine and 1,2,3-Benzotriazole vapors. Materials 15:1541. https://doi.org/10.3390/ma15041541

Goncharova OA, Kuznetsov YI, Andreev NN, Nad’kina EA (2016) Depositing nanolayers of volatile organic compounds on metals for higher resistance to atmospheric corrosion. Prot Met Phys Chem 52:1140–1146. https://doi.org/10.1134/S2070205116070078

Dudler V, Muinos C (1996) Diffusion of benzotriazoles in polypropylene - Influence of polymer morphology and stabilizer structure. Adv Chem Ser 249:441–453. https://doi.org/10.1021/ba-1996-0249.ch028

Chen T, Fu JJ (2012) pH-responsive nanovalves based on hollow mesoporous silica spheres for controlled release of corrosion inhibitor. Nanotechnology 23:235605. https://doi.org/10.1088/0957-4484/23/23/235605

Zheng QB, Xue QZ, Yan KO, Hao LZ, Li Q, Gao XL (2007) Investigation of molecular interactions between SWNT and polyethylene/polypropylene/polystyrene/polyaniline molecules. J Phys Chem C 111:4628–4635. https://doi.org/10.1021/jp066077c

Yan KY, Xue QZ, Xia D, Chen HJ, Xie J, Dong MD (2009) The core/shell composite nanowires produced by self-Scrolling carbon nanotubes onto copper nanowires. ACS Nano 3:2235–2240. https://doi.org/10.1021/nn9005818

Yang JS, Yang CL, Wang MS, Chen BD, Ma XG (2012) Isothermal crystallization of short polymer chains induced by the oriented slab and the stretched bundle of polymer: a molecular dynamics simulation. J Phys Chem B 116:2040–2047. https://doi.org/10.1021/jp209495w

Hill TL (1948) Steric Effects. I. Van der Waals Potential Energy Curves. J Chem Phys 16:399–404. https://doi.org/10.1063/1.1746902

Hirschfelder JO, Curtiss CF, Bird RB (1954) Molecular theory of gases and liquids. Wiley, New York

Zheng J, Wang DS, Song M, Jiao ML, Wang H (2022) Molecular dynamics simulation of effects of three accelerators on the microstructure of polyesters in non-aqueous solvents. Mater Today Commun 33:104404. https://doi.org/10.1016/j.mtcomm.2022.104404

Khaled KF (2009) Experimental and atomistic simulation studies of corrosion inhibition of copper by a new benzotriazole derivative in acid medium 54(18):4345–4352. https://doi.org/10.1016/j.electacta.2009.03.002

Wang ZW, Li B, Lin QB, Hu CY (2018) Two-phase molecular dynamics model to simulate the migration of additives from polypropylene material to food. Int J Heat Mass Transfer 122:694–706. https://doi.org/10.1016/j.ijheatmasstransfer.2018.02.004

Koopman EA, Lowe CP (2006) Advantages of a Lowe-Andersen thermostat in molecular dynamics simulations. J Chem Phys 124:204103. https://doi.org/10.1063/1.2198824

Berendsen HJC, Postma JPM, van Gunsteren WF, DiNola A, Haak JR (1984) Molecular dynamics with coupling to an external bath. J Chem Phys 81:3684. https://doi.org/10.1063/1.448118

Wang YH, Wang WH, Zhang ZQ, Xu LC, Li P (2016) Study of the glass transition temperature and the mechanical properties of PET/modified silica nanocomposite by molecular dynamics simulation. Eur Polym J 75:36–45. https://doi.org/10.1016/j.eurpolymj.2015.11.038

Lakshminarasimman N, Quinones O, Vanderford BJ, Campo-Moreno P, Dickenson EV, McAvoy DC (2018) Biotransformation and sorption of trace organic compounds in biological nutrient removal treatment systems. Sci Total Environ 640:62–72. https://doi.org/10.1016/j.scitotenv.2018.05.145

Herrero P, Borrull F, Pocurull E, Marce RM (2013) Efficient tandem solid-phase extraction and liquid chromatography-triple quadrupole mass spectrometry method to determine polar benzotriazole, benzothiazole and benzenesulfonamide contaminants in environmental water samples. J Chromatogr A 1309:22–32. https://doi.org/10.1016/j.chroma.2013.08.018

Krasevec I, Prosen H (2021) Determination of polar benzotriazoles in aqueous environmental samples by hollow-fibre microextraction method with LC-MS/MS and its comparison to a conventional solid-phase extraction method. Microchem J 166:106191. https://doi.org/10.1016/j.microc.2021.106191

Chen X, Lu LX, Qiu XL, Tang YL (2017) Controlled release mechanism of complex bio-polymeric emulsifiers made microspheres embedded in sodium alginate based films. Food Control 73:1275–1284. https://doi.org/10.1016/j.foodcont.2016.10.047

Crank J (1955) The mathematics of diffusion. Clarendon Press, Oxford. https://doi.org/10.2307/3609455

Frenkel D, Smit B (1996) Understanding Molecular Simulation: From Algorithms to Applications (second ed.), Academic Press, Inc ISBN: 0122673700. https://doi.org/10.1016/B978-0-12-267351-1.X5000-7

Maiti M, Bhowmick AK (2007) Effect of polymer-clay interaction on solvent transport behavior of fluoroelastomer-clay nanocomposites and prediction of aspect ratio of nanoclay. J Appl Polym Sci 105:435–445. https://doi.org/10.1002/app.26052

Sun B, Lu L, Zhu Y (2019) Molecular dynamics simulation on the diffusion of Flavor, O2 and H2O molecules in LDPE film. Materials 12:3515. https://doi.org/10.3390/ma12213515

Li B, Wang ZW, Lin QB, Hu CY (2017) Molecular dynamics simulation of three plastic additives’ diffusion in polyethylene terephthalate. Food Addit Contam: Part A 34:1086–1099. https://doi.org/10.1080/19440049.2017.1310398

Li H, Zhang X, Chu H, Qi G, Ding H, Gao X, Meng J (2022) Molecular simulation on permeation behavior of CH4/CO2/H2S mixture gas in PVDF at service conditions. Polymers 14:545. https://doi.org/10.3390/polym14030545

Zhang J, Yu WZ, Yu LJ, Yan YG, Qiao GM, Hu SQ, Ti Y (2011) Molecular dynamics simulation of corrosive particle diffusion in benzimidazole inhibitor films. Corros Sci 53:1331–1336. https://doi.org/10.1016/j.corsci.2010.12.027

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Funding

None.

Author information

Authors and Affiliations

Contributions

Xueyu Cheng: Methodology, Experiment performance, Validation, Data curation, Writing. Huan Ye: Experiment performance, Establishment of determination method. Chenghao Guo: Conceptualization, Experimental assistance. Liao Pan: Software assistance, Supervision. Lixin Lu: Conceptualization, Methodology, Supervision, Resources.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The microscopic diffusion mechanism of BTA in LDPE was computationally fulfilled

• The temperature dependence of BTA diffusion in LDPE was revealed;

• The influencing factors of BTA diffusion in LDPE were demonstrated;

• The interaction between BTA and VCIs was decisive in reducing the diffusion of BTA in LDPE.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cheng, X., Ye, H., Guo, C. et al. Molecular dynamics simulation of the effects of intermolecular interactions on the diffusion mechanism of 1,2,3-benzotriazole in low density polyethylene. J Polym Res 31, 109 (2024). https://doi.org/10.1007/s10965-024-03961-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-024-03961-1