Abstract

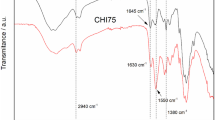

The synthesis of chitosan-based material (CHMAUR) of different forms (foam, porous and non-porous tough gels, porous dry) through crosslinking, facilitated by urea (UR) in the presence of malic acid (MA) as the organic acid, is reported. The new material was characterized extensively using FT IR spectroscopy, CP MAS solid state NMR spectroscopy, powder x-ray diffraction analysis and thermogravimetric analysis. Its structure was found to be independent of the form in which it was prepared. The porous dry form was characterized extensively. Its porosity was determined using helium gas pycnometry, ethanol displacement method while its morphology was examined using scanning electron microscopy. In this form, CHMAUR absorbed water rapidly and supported a compressive load of up to 15 MPa. With the ability to be machined using conventional tools and resistance to flame it might find use as an engineering material.

Similar content being viewed by others

References

Younes I, Rinaudo M, Harding D, Sashiwa H (2015) Chitin and chitosan preparation from marine sources. Structure, properties and applications. Mar Drugs 13:1133–1174

Rinaudo M (2006) Chitin and chitosan: Properties and applications. Prog Polym Sci 31:603–632

Hahn T, Tafi E, Paul A et al (2020) Current state of chitin purification and chitosan production from insects. J Chem Technol Biotechnol 95:2775–2795

Blair HS, Guthrie J, Law T, -K, Turkington P (1987) Chitosan and modified chitosan membranes I. Preparation and characterisation. J Appl Polym Sci 33:641–656

Fang J, Liao J, Zhong C et al (2022) High-Strength, Biomimetic Functional Chitosan-based hydrogels for full-thickness osteochondral defect repair. ACS Biomater Sci Eng 8:4449–4461

Sun Y, Chu Y, Deng C et al (2022) High-strength and superamphiphobic chitosan-based aerogels for thermal insulation and flame retardant applications. Colloids Surf Physicochem Eng Asp 651:129663

Yang J, Liu Y, Zhang ZZ et al (2022) Preparation protocol of urea cross-linked chitosan aerogels with improved mechanical properties using aqueous aluminum ion medium. J Supercrit Fluids 179:105414

Ganesan K, Heyer M, Ratke L, Milow B (2018) Facile Preparation of Nanofibrillar Networks of Ureido-Chitin Containing Ureido and Amine as Chelating Functional groups. Chem – A Eur J 24:19332–19340

Guerrero-Alburquerque N, Zhao S, Adilien N et al (2020) Strong, Machinable, and insulating Chitosan-Urea aerogels: toward ambient pressure drying of Biopolymer Aerogel Monoliths. ACS Appl Mater Interfaces 12:22037–22049

Takeshita S, Zhao S, Malfait WJ (2021) Transparent, Aldehyde-Free Chitosan Aerogel. Carbohydr Polym 251:117089

Narayanan A, Dhamodharan R (2015) Super water-absorbing new material from Chitosan, EDTA and urea. Carbohydr Polym 134:337–343

Narayanan A, Kartik R, Sangeetha E, Dhamodharan R (2018) Super water absorbing polymeric gel from Chitosan, citric acid and urea: synthesis and mechanism of water absorption. Carbohydr Polym J 191:152–160

Govindaraj P, Abathodharanan N, Ravishankar K et al (2019) Facile preparation of biocompatible macroporous chitosan hydrogel by hydrothermal reaction of a mixture of chitosan-succinic acid-urea. Mater Sci Eng C 104:109845. https://doi.org/10.1016/J.MSEC.2019.109845

Sangeetha E, Narayanan A, Dhamodharan R (2022) Super water-absorbing hydrogel based on chitosan, itaconic acid and urea: preparation, characterization and reversible water absorption. Polym Bull 79:3013–3030

Sangeetha E, Sharma R, Narayanan A et al (2022) Tough gels and Macroporous Foams based on Chitosan through Hydrothermal synthesis of Chitosan, Tartaric Acid, and Urea. ACS Appl Polym Mater 4:1764–1774

Paleckiene R, Sviklas A, Šlinkšiene R (2005) Reaction of urea with citric acid. Russ J Appl Chem 78:1651–1655

Radell J, Brodman BW, Domanski JJ (1967) Dicarboxylic Acid-Urea complexes. Angew Chemie Int Ed 71:1596–1601

Dutta A, Maity S, Das RK (2018) A highly stretchable, tough, Self-Healing, and Thermoprocessable polyacrylamide–Chitosan Supramolecular Hydrogel. Macromol Mater Eng 303:1–9

Xiang X, Chen G, Chen K et al (2020) Facile preparation and characterization of super tough chitosan/poly(vinyl alcohol) hydrogel with low temperature resistance and anti-swelling property. Int J Biol Macromol 142:574–582

Li Y, Sun S, Gao P et al (2021) A tough chitosan-alginate porous hydrogel prepared by simple foaming method. J Solid State Chem 294:121797

Sabnis S, Block LH (1997) Improved infrared spectroscopic method for the analysis of degree of N-deacetylation of Chitosan. Polym Bull 39:67–71

Zhang Y, Xue C, Xue Y et al (2005) Determination of the degree of deacetylation of chitin and chitosan by X-ray powder diffraction. Carbohydr Res 340:1914–1917

Ottøy MH, Vårum KM, Smidsrød O (1996) Compositional heterogeneity of heterogeneously deacetylated chitosans. Carbohydr Polym 29:17–24

Kasaai MR, Arul J, Charlet G (2000) Intrinsic viscosity-molecular weight relationship for chitosan. J Polym Sci Part B Polym Phys 38:2591–2598

Cho YI, No HK, Meyers SP (1998) Physicochemical characteristics and functional properties of various commercial chitin and Chitosan products. J Agric Food Chem 46:3839–3843

Han J, Zhou Z, Yin R et al (2010) Alginate–chitosan/hydroxyapatite polyelectrolyte complex porous scaffolds: Preparation and characterization. Int J Biol Macromol 46:199–205

Lei C, Wang Q, Li L (2009) Effect of interactions between poly(vinyl alcohol) and urea on the water solubility of poly(vinyl alcohol). J Appl Polym Sci 114:517–523

Heux L, Brugnerotto J, Desbrières J et al (2000) Solid state NMR for determination of degree of acetylation of chitin and chitosan. Biomacromol 1:746–751

Huang Y, He M, Lu A et al (2015) Hydrophobic modification of chitin whisker and its potential application in structuring oil. Langmuir 31:1641–1648

Ogawa K (1991) Effect of heating an aqueous suspension of Chitosan on the Crystallinity and Polymorphs. Agric Biol Chem 55:2375–2379

Ogawa K, Yui T (1993) Crystallinity of partially n-acetylated chitosans. Biosci Biotechnol Biochem 57:1466–1469

Acknowledgements

The first author thanks IIT Madras for Teaching cum Research Assistantship. We thank IIT Madras for financial support of this work. The Department of Civil Engineering, IIT Madras is thanked for facilities extended towards the helium pycnometry studies while Prof. Palaniappan Ramu and Mr. Suresh, Department of Engineering Design, are thanked for the facilities extended towards the compressive testing.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to state.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supporting Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharma, R., Dhamodharan, R. Synthesis and characterization of material derived from Chitosan, malic acid and urea. J Polym Res 31, 46 (2024). https://doi.org/10.1007/s10965-024-03891-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-024-03891-y