Abstract

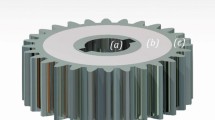

In this study, the effects of coating gear wheels made of PEEK material, which is frequently used in the industry, with the PVD method on the tribological performance were investigated. Spur gears with 6 modules, 15 teeth, and 20 mm surface width consisting of PEEK samples were used as the base material. Gears modeled in Solidworks were manufactured on a CNC milling machine. The coating process was performed with VCN target material in three different thicknesses. After the coating process, hardness and wear tests were applied to the samples. An increase in the hardness values of the samples coated in different thicknesses was observed compared to the pure PEEK material. As the coating thickness increased, the amount of wear on the gear wheels increased and it was determined that the most resistant sample against wear was the gear wheel with a coating thickness of 367 nm. In experiments conducted in different liquids, it was observed that the most wear occurred in NaCl solution.

Similar content being viewed by others

References

Abbasnezhad N, Khavandi A, Fitoussi J et al (2018) Influence of loading conditions on the overall mechanical behavior of polyether-ether-ketone (PEEK). Int J Fatigue 109:83–92

Cüreoğlu A, Şap E, Uzun M (2023) Mechanical analysis of PEEK samples coated using PVD method examining the features. JIST 13:1189–1198

Huo H, Cao L, Li J et al (2023) Tribological and mechanical behavior of tantalum and its compounds reinforced PEEK coatings for TKR. Surf Coat Technol 472:129964

Rodriguez V, Sukumaran J, Schlarb AK et al (2016) Influence of solid lubricants on tribological properties of polyetheretherketone (PEEK). Tribol Int 103:45–57

Rodriguez V, Sukumaran J, Schlarb AK et al (2016) Reciprocating sliding wear behaviour of PEEK-based hybrid composites. Wear 362–363:161–169

Matkovič S, Pogačnik A, Kalin M (2021) Wear-coefficient analyses for polymer-gear life-time predictions: a critical appraisal of methodologies. Wear 480–481:203944

Díez-Pascual AM, González-Domínguez JM, Teresa Martínez M et al (2013) Poly(ether ether ketone)-based hierarchical composites for tribological applications. J Chem Eng 218:285–294

Ferreira AA, Silva FJG, Pinto AG et al (2021) Characterization of thin chromium Coatings produced by PVD sputtering for Optical Applications. Coatings 11:215

Fallah P, Rajagopalan S, Mcdonald A et al (2020) Development of hybrid metallic coatings on carbon fiber-reinforced polymers (CFRPs) by cold spray deposition of copper-assisted copper electroplating process. Surf Coat Technol 400:126231

Maurer C, Schulz U (2013) Erosion resistant titanium based PVD coatings on CFRP. Wear 302:937–945

Hussain S, Rutledge L, Acheson JG et al (2020) The Surface Characterisation of Polyetheretherketone (PEEK) modified via the Direct Sputter Deposition of Calcium Phosphate Thin Films. Coatings 10:1088

Panjan P, Drnovšek A, Gselman P et al (2020) Review of growth defects in thin films prepared by PVD techniques. Coatings 10:447

Mohammed AS, Fareed MI (2016) Improving the friction and wear of poly-ether-etherketone (PEEK) by using thin nano-composite coatings. Wear 364–365:154–162

Polanec B, Zupanič F, Bončina T et al (2021) Experimental investigation of the wear Behaviour of Coated Polymer gears. Polymers 13:3588

Zhou X, Zhang Y, Guo P et al (2023) Tribological behavior of Cr/a-C multilayered coating against PEEK under dry sliding condition. Wear 518–519:204625

Dearn KD, Hoskins TJ, Petrov DG et al (2013) Applications of dry film lubricants for polymer gears. Wear 298–299:99–108

Caicedo JC, Gonzalez R, Caicedo HH et al (2016) Mechanical and tribological properties of V–C–N coatings as a function of applied bias voltage. J Superhard Mater 38:337–350

Ye Y, Jiang Z, Zou Y et al (2020) Enhanced anti-wear property of VCN coating in seawater with the optimization of bias voltage. Ceram Int 46:7939–7946

Yu L, Li Y, Ju H et al (2017) Microstructure, mechanical and tribological properties of magnetron sputtered VCN films. Surf Eng 33:919–924

Mu Y, Liu M, Zhao Y (2016) Carbon doping to improve the high temperature tribological properties of VN coating. Tribol Int 97:327–336

Cai Z, Pu J, Wang L et al (2019) Synthesis of a new orthorhombic form of diamond in varying-C VN films: microstructure, mechanical and tribological properties. Appl Surf Sci 481:767–776

Cüreoğlu A (2023) Ceramic coating of straight Gear Wheels made of PEEK (polyether ether ketone) material with PVD method and investigation of the wear behavior. Mechanical Engineering. İnönü University, Malatya/Turkey

Cüreoğlu A, Şap E, Uzun M (2022) Straight Gear Made of PEEK Material With PVD Method Investigation of Coverability. In: 2. International Black Sea Modern Scientific Research Congress. Rize/Turkey, pp 136–141

Grigore E, Ruset C, Luculescu C (2011) The structure and properties of VN-VCN-VC coatings deposited by a high energy ion assisted magnetron sputtering method. Surf Coat Technol 205:S29–S32

Acknowledgements

This study was produced from the master thesis titled “Ceramic Coating of Straight Gear Wheels Made of PEEK (Polyether Ether Ketone) Material with PVD Method and Investigation of The Wear Behavior”. Also, this work was supported by the Research Fund of the Inonu University (Project Number: BAP-2023-ID2991).

Funding

Inönü Üniversitesi, BAP-2023-ID2991, Mahir Uzun.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict Interests

The author(s) stated that they had no possible conflicts of interest in relation to the research, writing, and/or publishing of this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cüreoğlu, A., Uzun, M. & Şap, E. Effects of VCN coating of PEEK gears with the PVD method on wear performance. J Polym Res 31, 36 (2024). https://doi.org/10.1007/s10965-024-03884-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-024-03884-x